Description

Key Technical Specifications (For Spare Verification)

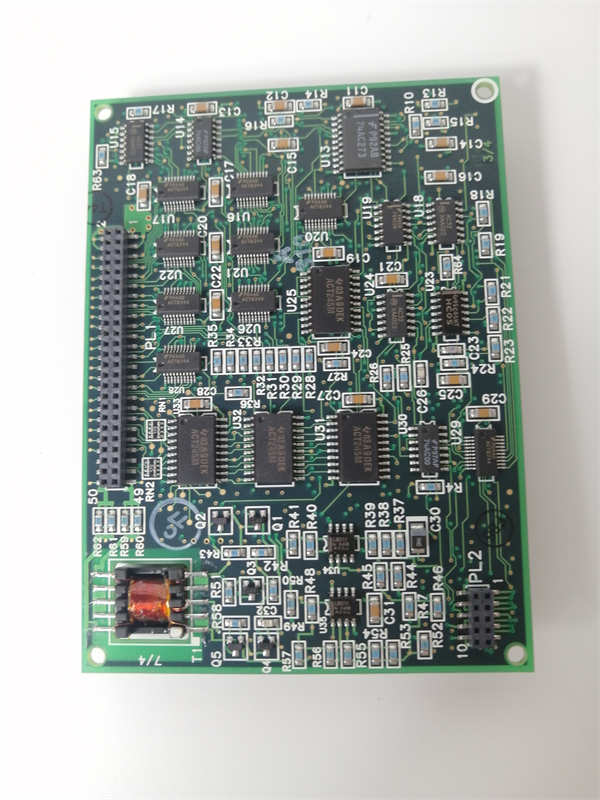

- Product Model: IC660ELB912J

- Manufacturer: GE Fanuc Automation (now Emerson)

- System Family: Genius I/O Series (Genius Bus-based distributed I/O)

- Output Channels: 8 isolated analog outputs

- Output Ranges: 4–20 mA (sink/source), 0–20 mA, 0–10 VDC (field-selectable via jumpers or software)

- Resolution: 12-bit

- Isolation: 500 V channel-to-channel and channel-to-bus

- Update Time: ~10 ms per rack (dependent on Genius bus configuration)

- Mounting: DIN-rail mountable block with removable terminal connectors

- Status Indicators: Power, fault, and module OK LEDs

System Role and Downtime Impact

The IC660ELB912J is a critical output interface in distributed control architectures using the GE Fanuc Genius I/O system, commonly found in water treatment plants, power generation facilities, and legacy manufacturing lines. It translates digital commands from the PLC into analog signals that drive final control elements such as modulating control valves, variable frequency drives (VFDs), and positioners. Loss of functionality in this module can result in loss of process regulation—for example, inability to adjust chemical dosing rates, boiler fuel flow, or motor speeds. In non-redundant installations, a single failed module may force manual operation or trigger safety interlocks, leading to partial or full plant shutdowns. Given its role in continuous processes, even degraded performance (e.g., output drift or slow response) can compromise product quality or regulatory compliance.

Reliability Analysis and Common Failure Points

Despite its rugged industrial design, the IC660ELB912J is subject to predictable wear mechanisms:

- DAC (Digital-to-Analog Converter) drift: Over time, internal reference voltages degrade, causing output offsets—especially noticeable in low-current ranges (e.g., 4 mA baseline errors).

- Output driver failure: Transistor or op-amp circuits driving the 4–20 mA loops can fail shorted or open due to sustained overloads or field wiring faults (e.g., shorted cables).

- Terminal block corrosion: Removable connectors are prone to oxidation in humid or corrosive environments, increasing contact resistance and signal instability.

- Power supply capacitor aging: Onboard filtering capacitors lose effectiveness, making the module susceptible to noise-induced glitches on the Genius bus.

A notable limitation is the absence of per-channel diagnostic feedback; the module reports only general fault status, complicating troubleshooting. To reduce risk, maintenance teams should:

- Conduct periodic loop calibration using precision current simulators

- Inspect and clean terminal blocks during scheduled outages

- Verify grounding integrity of the Genius bus shield and power commons

- Monitor output trends in the HMI for signs of drift or saturation

GE IC660ELB912J

Lifecycle Status and Migration Strategy

Emerson has officially discontinued the entire Genius I/O product line, including the IC660ELB912J. No new units are available, and factory repair or calibration services have been terminated. Continued use presents significant challenges: dwindling spare availability, lack of cybersecurity updates, and incompatibility with modern engineering tools.

As an interim solution, facilities may acquire tested-used modules from certified resellers or engage third-party specialists for board-level rework—though long-term reliability cannot be guaranteed.

The recommended migration path is to transition to Emerson PACSystems RSTi-EP I/O or VersaMax Nano platforms with Ethernet-based communication. These systems offer:

- Native support for EtherNet/IP and Modbus TCP

- Higher channel density and improved diagnostics

- Seamless integration with current versions of Proficy Machine Edition

- Ongoing firmware support and global service coverage

Migration typically involves replacing remote I/O heads while reusing existing field wiring through terminal adapters. Although requiring upfront engineering effort, this upgrade eliminates obsolescence risk, enhances process visibility, and aligns legacy infrastructure with contemporary industrial automation standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: