Description

Technical Specifications (For Spare Parts Verification)

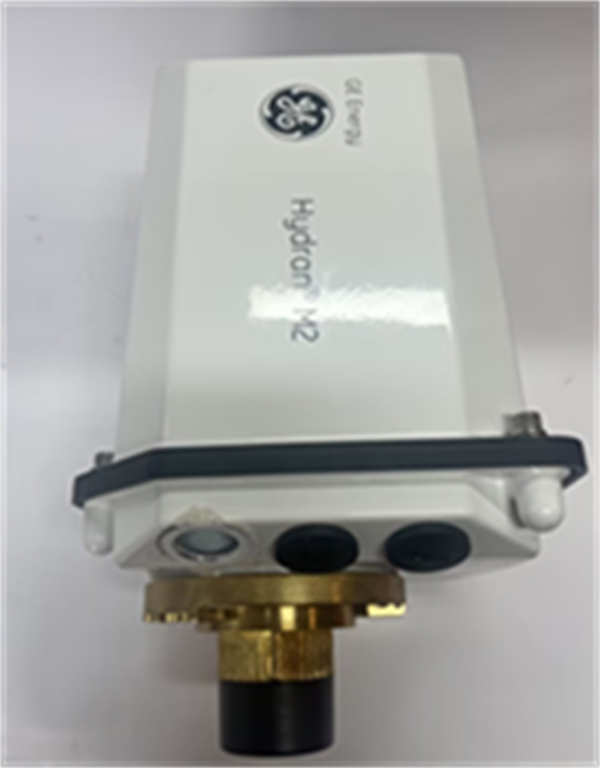

- Product Model: HYDRAN M2

- Manufacturer: GE Grid Solutions

- Associated System: Online transformer condition monitoring (standalone or integrated into SCADA via RTU)

- Measured Gases: Hydrogen (H₂) as primary indicator; optional CO sensor

- Output Signals: 2 × 4–20 mA (H₂ and CO), 2 × programmable alarm relays (SPDT)

- Power Supply: 24 VDC or 110/220 VAC (field-selectable)

- Oil Connection: DN25 flange (ISO 6162) or 1″ NPT, with built-in oil circulation pump

- Operating Temperature: -40°C to +70°C (outdoor-rated enclosure)

- Enclosure Rating: IP66 / NEMA 4X

- Calibration Interval: Typically 24 months (factory recommended)

- Communication: Analog only – no digital protocol support

System Role and Downtime Impact

The HYDRAN M2 is typically installed directly on the conservator tank or drain valve of high-voltage power transformers (69 kV and above) in transmission substations or industrial plants. It provides continuous measurement of hydrogen concentration—a key indicator of partial discharge, overheating, or arcing—enabling operators to detect developing faults weeks or months before catastrophic failure. If the unit fails (e.g., sensor drift, pump seizure, or electronics fault), the utility loses its primary real-time insight into transformer health. This forces reliance on infrequent lab-based DGA sampling (quarterly or annually), significantly increasing the risk of unexpected outages. In critical grid nodes, such a failure could delay maintenance planning, violate regulatory reliability standards (e.g., NERC PRC-002), or result in multi-million-dollar asset loss during a sudden internal fault.

Reliability Analysis and Common Failure Modes

Although engineered for harsh outdoor environments, the HYDRAN M2 exhibits several age-related failure mechanisms. The most common is oil pump degradation, where mechanical wear or particulate contamination reduces oil flow through the sensing chamber, causing slow response or false low readings. A second frequent issue is electrochemical sensor aging, particularly in high-humidity climates, leading to baseline drift or reduced sensitivity. Additionally, the analog output circuitry can develop offset errors due to capacitor aging on the signal conditioning board, resulting in inaccurate 4–20 mA signals that mislead SCADA systems.

A key design limitation is the absence of self-diagnostics or data logging. Unlike modern DGA monitors, the M2 cannot report internal status (e.g., pump runtime, sensor health), making it difficult to distinguish between a true gas event and an instrument fault. Furthermore, its reliance on analog outputs increases vulnerability to ground loops and EMI in electrically noisy substations.

Recommended preventive actions include:

- Annual verification using a certified gas-in-oil reference standard or portable DGA calibrator

- Inspection of oil inlet/outlet filters for clogging and pump operation noise

- Measurement of 4–20 mA loop impedance to ensure compatibility with RTU input cards

- Replacement of internal backup battery (if equipped for clock/calendar) to maintain event timestamping

GE HYDRAN M2

Lifecycle Status and Migration Strategy

GE (now Hitachi Energy) discontinued the HYDRAN M2 in favor of the HYDRAN M3 and 201Ti platforms, which offer digital communication (Modbus TCP, IEC 61850-7-420), multi-gas analysis (H₂, CO, CH₄, C₂H₂, etc.), and remote diagnostics via Hitachi’s eServ cloud platform. No factory repair or calibration services are available for the M2 beyond basic third-party support.

For utilities managing aging fleets, two interim approaches are practical:

- Strategic sparing: Secure multiple verified working M2 units now to cover remaining operational life (typically 5–7 years).

- Functional replacement: Install a modern DGA monitor (e.g., HYDRAN 201Ti) alongside the existing M2, using the new unit for monitoring while retaining the old for redundancy during transition.

The long-term migration path involves replacing the M2 with a HYDRAN 201Ti, which fits the same DN25 flange and requires minimal piping changes. However, integration into SCADA will shift from analog to digital (Modbus TCP over Ethernet), necessitating updates to RTU configuration and alarm logic. Given the critical role of DGA in asset risk management, delaying this upgrade increases exposure to undetected transformer degradation—making proactive replacement a prudent reliability investment.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: