Description

Technical Specifications (For Spare Part Verification)

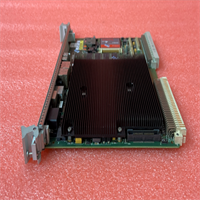

- Product Model: VME-7807RC (P/N: VME-7807RC-410000)

- Manufacturer: GE Power / GE Digital (USA)

- System Platform: GE Mark VI Integrated Turbine Control System

- Form Factor: 6U VMEbus module (233.35 mm x 160 mm)

- Processor: Motorola MPC860 or PowerPC-based embedded CPU (varies by revision)

- Memory: Onboard DRAM and flash; configuration stored on removable memory card (typically ATA Flash or SRAM with battery backup)

- Bus Interface: VME64 (32-bit, 33 MHz) backplane communication

- I/O Support: Interfaces with I/O packs via high-speed serial links (not direct field I/O)

- Power Requirement: +5 V DC, ±12 V DC from VME chassis (typical draw: ~5 A on +5V rail)

- Operating Temperature: 0°C to +60°C (requires active cooling in control cabinet)

System Role and Downtime Impact

The VME-7807RC is the primary CPU module in the GE Mark VI turbine control system, serving as the central decision-making unit for gas and steam turbines in power plants and industrial facilities. It executes the control logic for startup, synchronization, load control, and emergency shutdown sequences. If this module fails—due to hardware fault, memory corruption, or power anomaly—the entire Mark VI system loses its ability to command actuators (e.g., fuel valves, IGVs), resulting in an immediate turbine trip. In combined-cycle or baseload power plants, such a failure can lead to a full plant outage lasting days, with financial impacts exceeding hundreds of thousands of dollars per incident.

Reliability Analysis and Common Failure Modes

Despite its robust design, the VME-7807RC is susceptible to age-related degradation due to its early-2000s architecture. The most frequent failure modes include:

- Battery-backed memory loss: The module relies on a lithium coin cell (e.g., BR2330) to retain configuration during power cycles. After 10–15 years, these batteries deplete, causing program or parameter loss upon reboot.

- Electrolytic capacitor aging: Power regulation circuits on the board contain aluminum electrolytic capacitors that dry out over time, leading to voltage instability and intermittent crashes.

- VME connector wear: Repeated thermal cycling causes micro-cracks in the edge connector fingers, resulting in poor backplane contact and system resets.

- Flash memory wear-out: The onboard ATA flash card (if used) has limited write cycles; repeated firmware updates or logging can cause corruption.

Key design weaknesses include dependence on non-replaceable onboard batteries and lack of error-correcting code (ECC) memory. For preventive maintenance, operators should:

- Replace the backup battery every 5–7 years (even if voltage appears normal)

- Inspect and clean VME edge connectors annually using contact enhancer

- Monitor CPU temperature and ensure cabinet cooling fans are functional

- Maintain at least one verified spare module under controlled storage conditions

VME-7807RC VME-7807RC-410000 GE

Lifecycle Status and Migration Strategy

GE officially discontinued the VME-7807RC as part of the Mark VI end-of-life roadmap, with Mark VIe (based on PC/104+ and later CompactPCI) designated as the successor platform. Continuing to operate Mark VI systems carries significant risk: no factory support, no warranty, and dwindling global spare inventory. Lead times for functional units now exceed 6–12 months, and prices have risen sharply.

As a temporary measure, facilities may:

- Source tested, refurbished units from specialized industrial automation suppliers

- Perform board-level repair (e.g., capacitor rework, battery replacement) through certified third parties

- Implement redundant CPU configurations (if originally designed with dual controllers)

For long-term sustainability, GE recommends migrating to the Mark VIe platform. This upgrade involves replacing the entire controller chassis, I/O packs, and engineering workstation, along with re-commissioning of all control logic. While capital-intensive, the migration delivers modern cybersecurity features, IEC 61850 support, remote diagnostics, and extended lifecycle assurance—making it the only viable path for plants planning operation beyond 2030.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: