Description

Technical Specifications (For Spare Parts Verification)

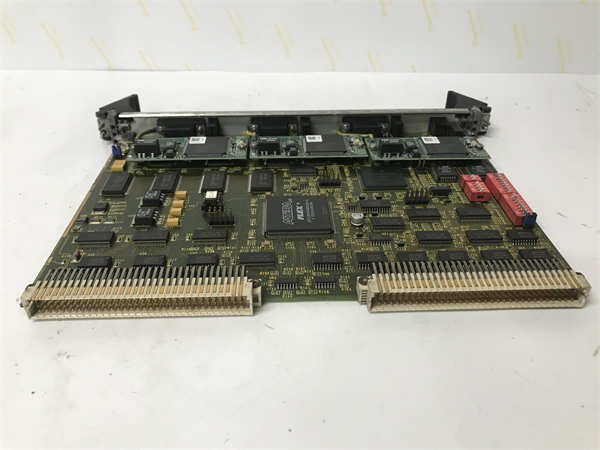

- Model: EVPBDP0001 / EVPBDP032

- Manufacturer: GE Fanuc Automation (now Emerson)

- System Family: VersaMax PLC / I/O System

- EVPBDP0001 Type: 1-slot empty carrier base (used for single I/O module installation)

- EVPBDP032 Type: 32-point high-density digital I/O base (integrated terminal block, no separate module required)

- Mounting Style: DIN rail compatible with VersaMax bus base (EVPBUSxx series)

- Connector Interface: Matches VersaMax backplane pinout (proprietary 48-pin edge connector)

- Terminal Type: Screw terminals (EVPBDP032) or open slots for plug-in modules (EVPBDP0001)

- Operating Voltage: Powered via VersaMax backplane (24 VDC nominal)

- Physical Dimensions: Standard VersaMax width (approx. 22 mm per slot)

- Key Visual ID: EVPBDP0001 has no terminals; EVPBDP032 has two rows of 16 screw terminals labeled “I0–I15” or “Q0–Q15”

System Role and Downtime Impact

The GE EVPBDP0001 and EVPBDP032 are foundational hardware components in legacy VersaMax distributed I/O systems. The EVPBDP0001 serves as a passive carrier that allows a single plug-in I/O module (e.g., EVPMDCxxx) to connect to the VersaMax network. The EVPBDP032 is a self-contained 32-point digital I/O base with built-in wiring terminals—functionally equivalent to a module and base combined.

If either unit fails—due to cracked PCB, damaged backplane connector, or corroded terminals—the connected I/O points become unresponsive. In critical applications such as water treatment pump control, boiler safety interlocks, or conveyor sequencing, this can result in partial or full process shutdown. Because these bases are not field-repairable and lack active electronics redundancy, their failure directly translates to lost production until a verified replacement is installed.

Reliability Analysis and Common Failure Modes

These bases have no active components, which contributes to their long field life—many units have operated reliably for 15–20 years. However, their mechanical and environmental exposure makes them vulnerable to specific failure modes.

Common failure patterns include:

- Backplane connector wear or oxidation, leading to intermittent communication or complete loss of I/O scan.

- Terminal block screw stripping or thermal cycling fatigue, causing loose wiring and signal dropout.

- PCB delamination or trace cracking due to vibration in industrial environments (especially near motors or compressors).

- Corrosion on terminal screws or copper traces in high-humidity or chemical-exposure areas.

Design weaknesses stem from their reliance on mechanical integrity: there is no diagnostic feedback if a terminal is loose or a connector is partially seated. Additionally, the EVPBDP032’s integrated design means a single point of physical damage can disable all 32 I/O points.

Preventive maintenance recommendations:

- Inspect terminal tightness during routine outages using calibrated torque screwdrivers.

- Clean backplane connectors with contact enhancer spray if communication errors occur.

- Verify DIN rail mounting stability to minimize vibration-induced stress.

- Store spare units in climate-controlled, anti-static packaging to prevent latent damage.

GE EVPBDP0001 EVPBDP032

Lifecycle Status and Migration Strategy

GE officially discontinued the entire VersaMax product line years ago, with no direct replacements offered under the current Emerson portfolio. Continued use carries significant risk: genuine new-old-stock (NOS) inventory is nearly exhausted, and secondary market units may have unknown usage history or counterfeit components.

As a temporary measure, facilities can:

- Secure tested spares from certified surplus suppliers with functional verification reports.

- Implement board-level repair services for units with minor terminal or connector damage.

- Isolate critical I/O onto redundant circuits where feasible.

For long-term sustainability, migration is strongly advised. The recommended path is to transition to the Emerson PACSystems RX3i or RXi2 platform. This requires:

- Replacing VersaMax CPU and I/O racks with RX3i equivalents.

- Rewiring field devices to new I/O modules (e.g., IC695MDL754 for 32-point digital).

- Converting logic from Proficy Machine Edition (VersaMax) to PACMachine Edition or CODESYS-based engineering tools.

While migration involves upfront engineering effort, it eliminates ongoing obsolescence risk, improves cybersecurity posture, and enables integration with modern SCADA and IIoT platforms via OPC UA and Ethernet/IP. A phased approach—starting with non-critical subsystems—can minimize disruption while building internal competency on the new architecture.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: