Description

Technical Specifications (For Spare Verification)

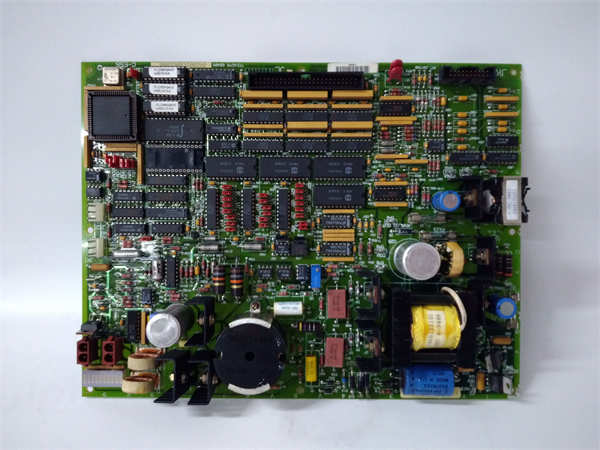

- Product Models: DS200TCEAG1BNE (rack-mounted module), DS215TCEAG1BZZ01A (front-access terminal board)

- Manufacturer: General Electric (GE Power / formerly GE Industrial Systems)

- System Family: Mark V Gas Turbine Control System (used in Frame 5, 6, 7, and 9 turbines)

- Function: Analog and digital I/O expansion adapter with signal conditioning and isolation

- Compatibility: Must be used as a matched pair; DS215 board plugs directly into DS200 module

- I/O Capacity: Supports up to 32 analog inputs (typically 4–20 mA or ±10 V) and multiple discrete I/O channels

- Backplane Interface: Connects to Mark V core rack via VME-style bus (requires specific slot assignment)

- Diagnostic Features: Limited LED indicators for power and communication status

- Firmware Dependency: Requires correct PROM version on associated controllers (e.g., STCA, PTBA)

- Mechanical Form Factor: Standard Mark V 6U card size with keyed connector to prevent mis-mating

-

DS200TCEAG1BNE DS215TCEAG1BZZ01A

System Role and Downtime Impact

The DS200TCEAG1BNE and its companion terminal board DS215TCEAG1BZZ01A form a critical I/O interface layer in the GE Mark V control architecture. They reside between the turbine’s field instrumentation (e.g., speed probes, LVDTs, pressure transmitters) and the central control processors. This TCEA pair is often deployed for auxiliary systems such as lube oil pressure monitoring, inlet guide vane control, or exhaust temperature profiling. If either component fails—due to internal circuit damage, connector corrosion, or firmware mismatch—the associated I/O signals become invalid. In many configurations, loss of key analog inputs (e.g., bearing vibration) will automatically force a turbine trip or prevent synchronization to the grid. Recovery requires replacement of the entire TCEA assembly, as the terminal board cannot function without its base module. Given that Mark V systems often operate in baseload or peaking power plants, unplanned downtime due to TCEA failure can result in revenue losses exceeding $100,000 per day.

Reliability Analysis and Common Failure Modes

Despite being solid-state, the TCEA assembly is vulnerable to several age- and environment-related failure mechanisms:

- Electrolytic capacitor degradation on the DS200 board, leading to power supply ripple and erratic I/O readings.

- Corrosion or oxidation on the high-density connector between the DS200 and DS215 boards, causing intermittent signal loss—especially in humid or coastal environments.

- Damage to analog input protection circuits from voltage surges (e.g., during lightning events or generator switching), resulting in channel drift or complete failure.

Design weaknesses include limited overvoltage protection on field terminals and reliance on aging surface-mount components not rated for >25-year service. The DS215 terminal board uses screw terminals that can loosen over time due to thermal cycling, increasing contact resistance.

Preventive maintenance should include:

- Annual inspection of terminal tightness and signs of arcing on the DS215 board.

- Thermal imaging of the DS200 module during operation to detect hot spots indicating failing regulators.

- Verification of I/O calibration drift using a known reference source during scheduled outages.

- Storage of spares in climate-controlled, anti-static packaging to avoid latent damage.

-

DS200TCEAG1BNE DS215TCEAG1BZZ01A

Lifecycle Status and Migration Strategy

GE has formally discontinued the DS200/DS215 TCEA series as part of the end-of-life plan for the Mark V platform. No new units are available through official channels, and GE no longer provides repair or calibration services. Continuing to operate with these modules carries escalating risk: the global pool of tested, functional units is shrinking, and counterfeit or previously failed boards are increasingly common in the gray market.

As a short-term mitigation, operators should:

- Secure at least one verified, tested spare set per turbine.

- Partner with specialized third-party vendors offering board-level refurbishment (including capacitor replacement and conformal coating).

- Implement redundant I/O paths where possible to isolate single-point failures.

For long-term sustainability, GE recommends migrating to the Mark VIe or Mark VIeS control platform. This transition replaces the entire I/O architecture with modern, Ethernet-based I/O packs (e.g., VSVO, VSAO) and eliminates dependency on obsolete VME hardware. While migration requires significant engineering effort—including logic conversion, loop re-commissioning, and operator training—it restores access to cybersecurity updates, remote diagnostics, and guaranteed spare parts. Facilities with extended asset life plans should initiate feasibility studies now, as lead times for migration projects exceed 18 months. Until then, rigorous spares management and condition monitoring remain essential to avoid catastrophic turbine trips.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: