Description

Key Technical Specifications (For Spare Parts Verification)

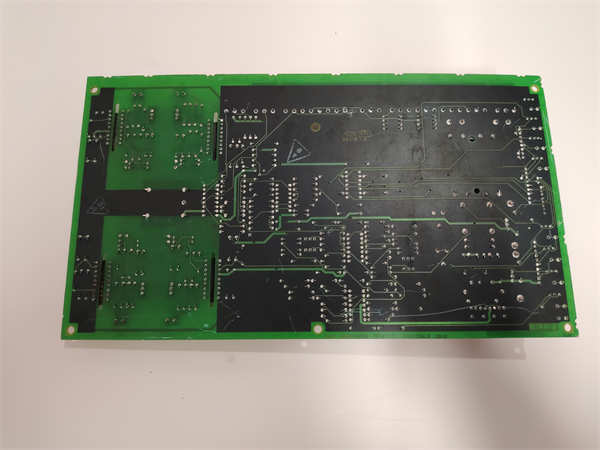

- Product Model: DS200SIOCG1AEA

- Manufacturer: General Electric (GE Power / GE Vernova)

- System Family: Mark V Speedtronic Turbine Control System

- Board Type: Serial Input/Output Controller (SIOC) – G1 revision, AEA variant

- Form Factor: Plug-in PCB module for Mark V core rack (typically mounted in core)

- Communication Interfaces: Dual redundant STBN (Serial Time Division Bus Network) links to main processors (, , )

- I/O Connectivity: Interfaces with DTBC terminal boards and I/O packs (e.g., DCC, DTAO, DTAI) via ribbon cables

- Diagnostic Features: Onboard LEDs for power, activity, and fault status; error codes via Mark V HMI

- Firmware Dependency: Requires specific PROM versions aligned with turbine application code (e.g., gas turbine vs. steam turbine)

- Power Supply: +5 V, ±15 V from Mark V backplane

- Compatibility: Mark V systems with G1-series hardware; not compatible with Mark VI or VIe

System Role and Downtime Impact

The DS200SIOCG1AEA is a mission-critical component within the triple-modular redundant (TMR) architecture of the GE Mark V control system. It serves as the primary data conduit between the three main control processors and the distributed I/O subsystems that monitor and actuate field devices—such as fuel valves, vibration sensors, pressure switches, and generator breakers. In normal operation, it ensures synchronized, fault-tolerant signal exchange across all channels. If this board fails or becomes unresponsive, the affected control core may lose I/O communication, triggering a “core fault” and potentially forcing a turbine trip or preventing restart. Given that most Mark V installations operate without full hot-spare redundancy at the SIOC level, replacement typically requires a controlled shutdown. Extended downtime is common due to parts scarcity and the need for post-installation validation through loop checks and functional tests.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the DS200SIOCG1AEA is now vulnerable to age-related failures due to its early-1990s to early-2000s manufacturing era. The most prevalent issues include degradation of surface-mount electrolytic capacitors on the power regulation circuitry, leading to voltage instability, intermittent resets, or complete board lockup. Additionally, repeated thermal cycling can cause hairline cracks in solder joints—particularly around high-pin-count connectors—resulting in intermittent communication faults that are difficult to diagnose. The board’s reliance on proprietary ASICs and PROMs also presents a hidden risk: latent bit errors in firmware memory can corrupt communication protocols without obvious hardware failure. A known weakness is sensitivity to electrical noise or ground loops in older plant wiring, which may induce false trip signals. Preventive measures include periodic visual inspection for capacitor bulging, cleaning dust from ventilation paths, verifying secure seating in the backplane, and maintaining up-to-date system backups to facilitate rapid recovery.

DS200SIOCG1AEA GE

Lifecycle Status and Migration Strategy

GE has formally discontinued the DS200SIOCG1AEA as part of the broader obsolescence of the Mark V platform. No new units are available through official channels, and technical support is limited to legacy service contracts. Continuing to operate with this hardware entails significant operational risk: spare parts are increasingly unreliable, counterfeit boards may lack proper firmware, and diagnostic tools (e.g., Toolbox software) face compatibility challenges with modern operating systems. Short-term mitigation includes sourcing tested-used units from certified vendors, implementing rigorous pre-installation burn-in testing, and maintaining a small inventory of verified spares. The strategic long-term solution is migration to GE’s current control platform—Mark VIe—which offers enhanced cybersecurity, modern I/O architectures, and cloud-enabled diagnostics. This transition typically involves replacing the entire control core, re-engineering application logic, and re-commissioning I/O—requiring substantial planning but delivering improved reliability, regulatory compliance, and lifecycle sustainability for critical power assets.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: