Description

Key Technical Specifications (For Spare Parts Verification)

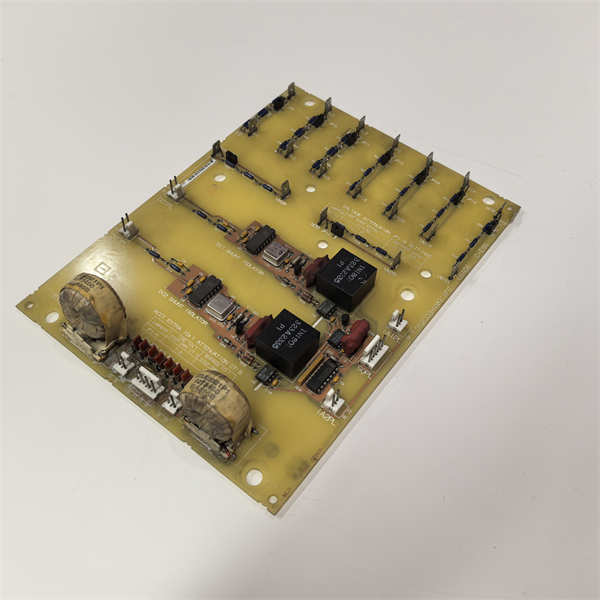

- Product Model: DS200SHVMG1AFE

- Manufacturer: General Electric (GE Power / GE Vernova)

- System Family: Mark V Speedtronic Control System

- Board Type: High-Voltage Module (SHVM), G1 revision, AFE variant

- Primary Function: Generates phase-controlled gate pulses for SCRs/thyristors in exciter or motor drive bridges

- Input Interface: Receives firing angle commands from DTBC terminal board via ribbon cable

- Output: Isolated high-voltage gate drive signals (typically ±15 V to ±30 V pulses at several amps peak)

- Isolation: Reinforced galvanic isolation between control logic and power electronics (≥2.5 kV)

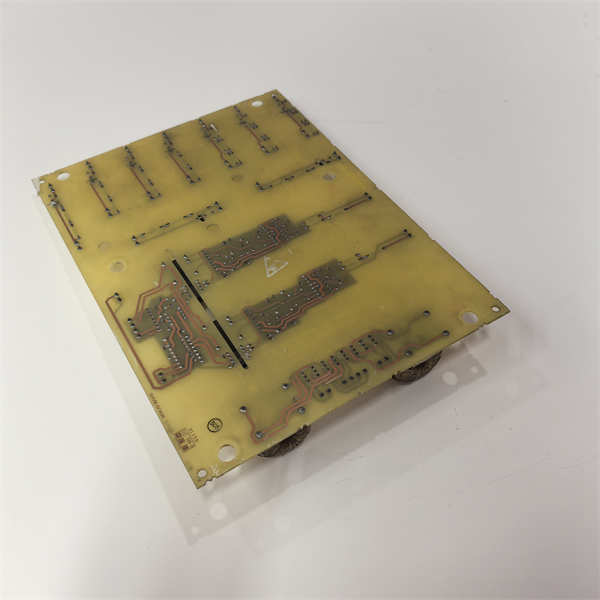

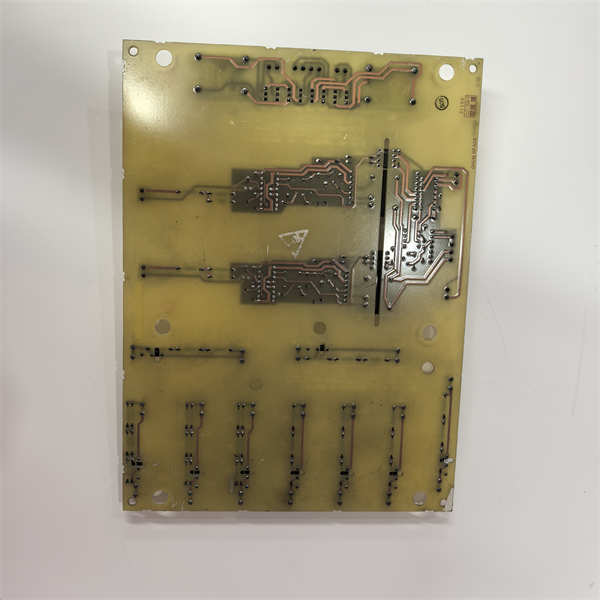

- Mounting: Vertical PCB mount in Mark V core rack, adjacent to DTBC and power supply modules

- Diagnostic Indicators: Onboard LEDs for power status and fault conditions (e.g., overcurrent, sync loss)

- Compatibility: Mark V systems with G1-series hardware; used primarily in static excitation (EX2000/EX2100-era) or large motor applications

System Role and Downtime Impact

The DS200SHVMG1AFE is a critical interface between the Mark V’s low-voltage control logic and the high-power thyristor bridges used in generator excitation or large synchronous motor drives. It translates digital firing commands into precisely timed, high-current gate pulses that control the conduction angle of SCRs—directly governing field current, terminal voltage, or motor torque. Failure of this module typically results in loss of excitation (leading to generator under-excitation trips) or uncontrolled motor torque, often triggering immediate turbine or motor shutdown. Because the SHVM operates in a high-noise, high-voltage environment, its failure can also damage connected power semiconductors if gate signals become erratic. Replacement requires system de-energization, careful handling due to stored energy in capacitors, and post-installation validation of firing angles and waveform symmetry—processes that are time-consuming and heavily dependent on spare part availability.

Reliability Analysis and Common Failure Modes

The DS200SHVMG1AFE is exposed to harsh electrical stresses, making it prone to specific age-related failure mechanisms. The most common issues involve degradation of high-voltage optocouplers or pulse transformers used for isolation, leading to timing drift, reduced gate drive strength, or complete signal dropout. Electrolytic capacitors in the local power supply section frequently dry out over time, causing unstable bias voltages and intermittent operation—especially under thermal cycling. Additionally, the board’s high-current output traces and connectors are susceptible to corrosion or micro-cracking, which increases impedance and reduces gate drive fidelity. A design vulnerability is the lack of real-time self-diagnostics for individual channel health; faults may only manifest during load transients. For preventive maintenance, technicians should periodically inspect for burnt components, verify gate pulse waveforms with an oscilloscope during scheduled outages, ensure clean and tight connections to the DTBC board, and monitor excitation system performance trends for early signs of instability.

GE DS200SHVMG1AFE

Lifecycle Status and Migration Strategy

GE has discontinued the DS200SHVMG1AFE as part of the Mark V platform’s end-of-life cycle. No new units are available, and official support is restricted to legacy service agreements with diminishing resources. Continued use carries substantial risk: untested surplus modules may fail prematurely, counterfeit units may lack proper isolation ratings, and firmware/hardware mismatches can cause system instability. Short-term mitigation includes sourcing boards from certified vendors with full functional test reports, implementing burn-in procedures before installation, and maintaining a small inventory of verified spares. The long-term solution is migration to GE’s modern Mark VIe control platform, which integrates excitation control via digital I/O and high-speed analog outputs, eliminating the need for discrete high-voltage gate driver cards. This transition typically involves replacing the excitation controller (e.g., upgrading to EX2100e), re-engineering control logic in ToolboxST, and re-commissioning the entire excitation loop. While capital-intensive, this path restores access to cybersecurity updates, predictive diagnostics, and sustainable technical support—critical for maintaining reliability in power generation and industrial drive applications.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: