Description

Key Technical Specifications (For Spare Part Verification)

- Product Model: DS200PCCAG5ACB

- Manufacturer: General Electric (GE)

- System Family: Mark V Turbine Control System

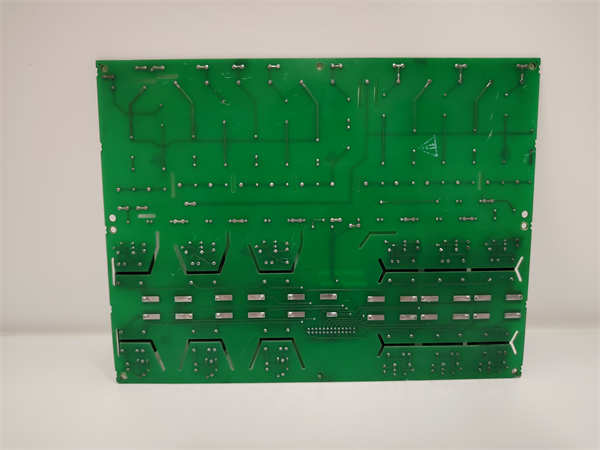

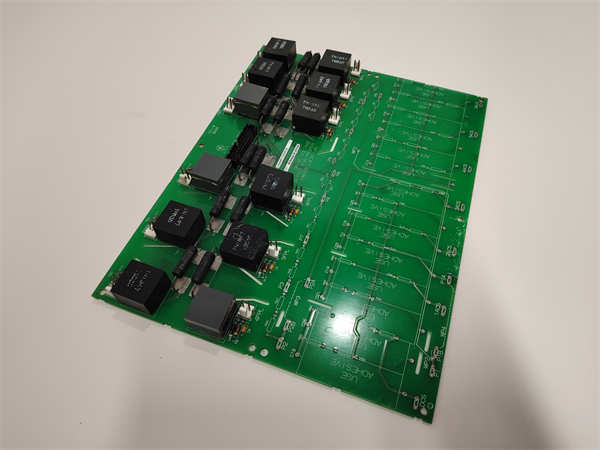

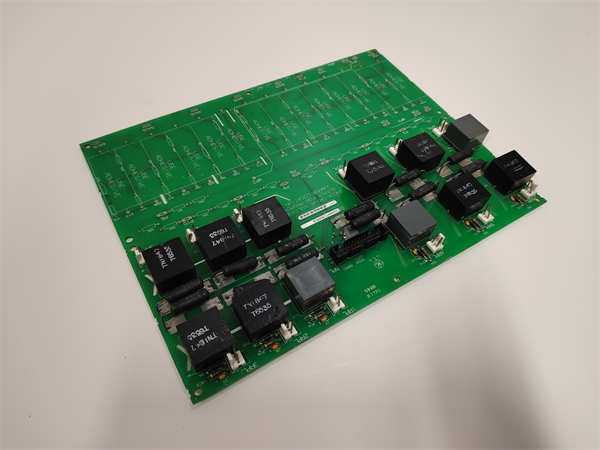

- Board Type: Power Connect Card (PCCA), Revision G5, Variant ACB

- Function: Distributes +5V, ±15V, and +24V DC to I/O cards; routes TTL-level signals between , , and controller cores and terminal boards

- Connector Types: High-density AMPMODU backplane connectors, power terminals, and diagnostic headers

- Mounting: Vertical insertion in Mark V core chassis (typically slot 1 or 2)

- Diagnostic Features: LEDs for power rails and core synchronization status (depending on revision)

- Compatibility: Must match exact revision (G5) and variant (ACB); not interchangeable with earlier G1–G4 or other suffixes

- Form Factor: Full-height Eurocard (approx. 233 mm × 160 mm)

System Role and Downtime Impact

The DS200PCCAG5ACB serves as the electrical backbone of the Mark V control core. It supplies regulated power to all I/O terminal boards (e.g., TCQA, VCMA, LAQA) and enables inter-core communication between the triple-redundant processors (, , ). A malfunction—such as voltage dropout, short circuit, or signal trace failure—can cause partial or complete loss of I/O scanning, leading to turbine trip or forced manual operation. Because the PCCA is not redundant within a single core, its failure directly compromises system integrity. In combined-cycle or baseload power plants, this often results in an unplanned outage lasting 24–72 hours, depending on spare availability and troubleshooting complexity.

Reliability Analysis and Common Failure Modes

The PCCA operates under continuous electrical load and is vulnerable to long-term thermal stress. The most frequent failure points are cracked solder joints around high-current power pins due to thermal cycling, and degradation of tantalum capacitors on the +5V and +24V rails, which can lead to voltage sag or short circuits. The board’s dense through-hole design and use of older FR-4 PCB material also make it susceptible to moisture ingress and dendritic growth in humid environments, especially if cabinet air conditioning fails. Additionally, repeated card insertions during maintenance can wear backplane connectors, causing intermittent contact. Recommended preventive actions include annual thermographic inspection of power traces, visual checks for capacitor leakage or bulging, verification of cabinet humidity (<60% RH), and gentle handling during removal/installation to avoid mechanical stress on connectors.

DS200PCCAG5ACB GE

Lifecycle Status and Migration Strategy

GE has officially discontinued the DS200PCCAG5ACB as part of the Mark V platform’s end-of-life declaration. No new units are available, and GE no longer provides repair services, firmware support, or replacement documentation for this revision. Continued operation relies entirely on the secondary market, where prices have risen significantly and authenticity cannot always be guaranteed. As a stopgap, some operators maintain “known-good” spares stored in climate-controlled conditions and perform periodic bench testing. However, the only sustainable path is migration to a modern control system. GE’s strategic replacement is the Mark VIe, which integrates control, protection, and sequencing into a single scalable platform with Ethernet-based I/O and enhanced cybersecurity. Migration requires full re-engineering of logic (from Ladder/State Logic to ToolboxST applications), replacement of I/O modules, and updated HMI integration—but eliminates obsolescence risk, reduces footprint, and enables remote diagnostics and predictive maintenance via GE’s OpCenter solutions.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: