Description

Key Technical Specifications (For Spare Parts Verification)

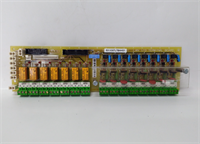

- Product Model: DS200PCCAG1ACB

- Manufacturer: General Electric (GE)

- System Family: Mark V Turbine Control System (Triple Modular Redundant – TMR)

- Module Type: Primary Control Card A (PCCA)

- Function: Handles I/O processing, serial communications (to HMI, EEPROM, TCQA), and co-processor coordination

- Form Factor: Plug-in PCB module for Mark V core rack

- Firmware Dependency: Requires matching PROM/EPROM version aligned with system software (e.g., CSP, CDB)

- Connector Type: Dual 96-pin DIN backplane connectors

- Diagnostic Indicators: Onboard LEDs for power, CPU activity, and fault status

- Operating Environment: Designed for industrial control room conditions (typically 0–50°C, non-condensing)

System Role and Downtime Impact

The DS200PCCAG1ACB is a foundational component of the GE Mark V turbine control system, which governs startup, synchronization, load control, and emergency shutdown for gas and steam turbines. As one of three primary control cards (PCCA, PCCB, PCCC) in the TMR architecture, it participates in continuous voting to ensure fault tolerance. While the Mark V can tolerate a single PCC failure, loss of a second card forces a turbine trip. The PCCA specifically manages critical I/O channels and serves as the main communication gateway to the operator interface (HMI) and engineering tools. If this module fails unexpectedly—especially in a degraded (already one-failed) system—it can trigger an immediate, uncontrolled turbine shutdown. In power generation or mechanical drive applications, such an event may result in lost revenue, grid instability, or mechanical stress on rotating equipment.

Reliability Analysis and Common Failure Modes

Despite its ruggedized design, the DS200PCCAG1ACB is prone to age-related failures due to decades of service in high-availability environments. Common issues include:

- EPROM/EEPROM corruption after repeated power cycles or battery backup depletion

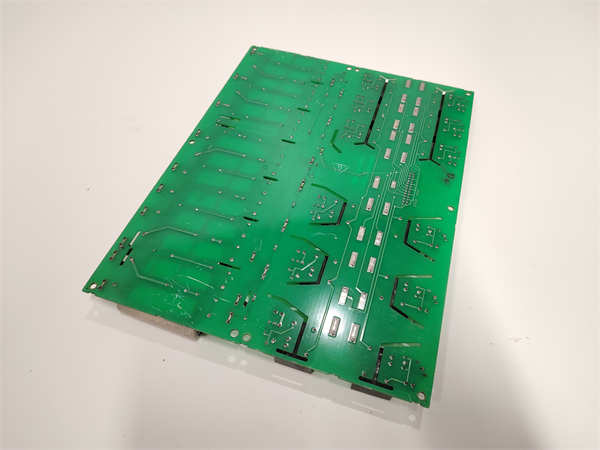

- Solder joint fatigue on high-pin-count connectors due to thermal cycling

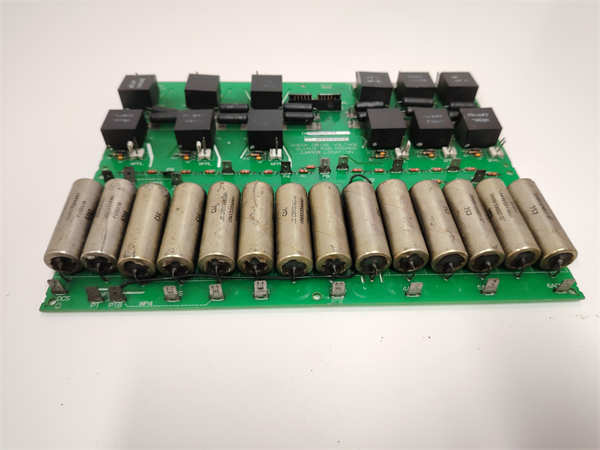

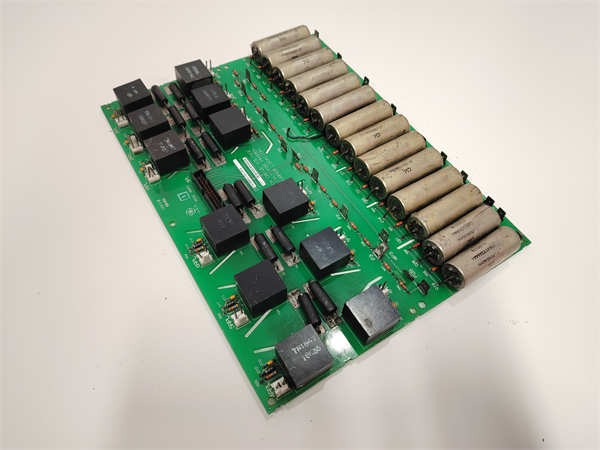

- Capacitor aging on the analog and power regulation sections, leading to voltage instability

- Serial communication chip degradation, causing intermittent loss of HMI link or EEPROM sync errors

A key vulnerability is its dependence on legacy components (e.g., discrete logic ICs, through-hole capacitors) that are no longer manufactured. Additionally, the board lacks modern ESD or surge protection on field wiring interfaces, making it sensitive to grounding issues or transient events.

Recommended preventive actions:

- Monitor battery voltage on the associated TCQA or TCEA boards (backup for configuration memory)

- Perform periodic “cold start” validation during outages to verify boot integrity

- Inspect connector pins for oxidation or bent contacts during maintenance windows

- Maintain consistent firmware versions across all PCC modules to avoid mismatch faults

- Store spares in anti-static, dry, temperature-controlled environments

GE DS200PCCAG1ACB

Lifecycle Status and Migration Strategy

GE has formally discontinued the DS200PCCAG1ACB as part of the broader Mark V end-of-life strategy. No new units are available from GE Vernova. Remaining supply exists only through third-party refurbishers or decommissioned sites, often at 3–6× original list price, with no warranty or functional guarantee. GE’s official support for Mark V is now limited to extended service contracts, and software tools (e.g., Toolbox) receive no updates.

Short-term mitigation includes:

- Securing multiple tested spares from reputable vendors

- Implementing board-level repair programs with specialized electronics firms

- Isolating the Mark V from modern networks to reduce cybersecurity exposure

The long-term solution is migration to Mark VIe or Mark VIeS, GE’s current-generation control platforms. This transition offers enhanced diagnostics, Ethernet-based I/O, compliance with IEC 62443, and integration with Predix or other digital asset performance tools. However, migration requires full re-engineering of control logic, I/O rewiring, recertification of protection functions, and operator retraining—making it a multi-month capital project best executed during major overhauls. Proactive planning is essential to avoid forced outages due to unrecoverable hardware failure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: