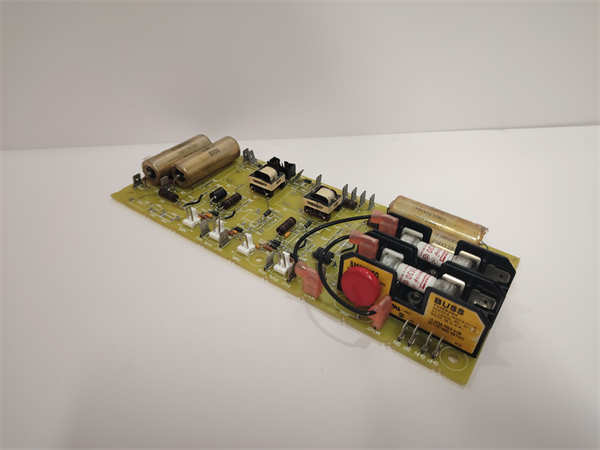

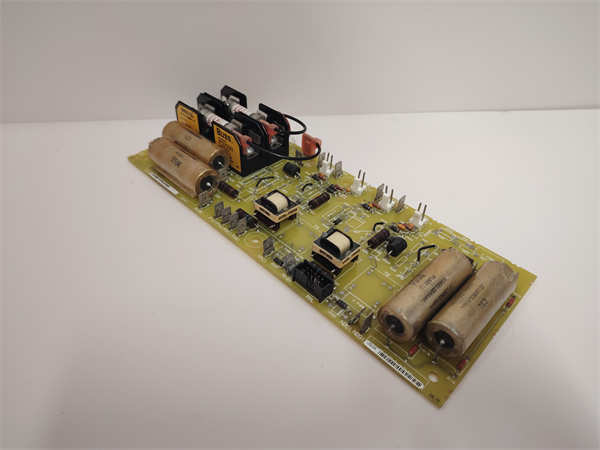

Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: DS200FSAAG2ABA

- Manufacturer: General Electric (GE Power / GE Vernova)

- System Family: Mark V Speedtronic Turbine Control System

- Board Type: Fuel Stroke Actuator Analog Output Board (FSA), G2 revision, ABA variant

- Output Channels: Typically 2–4 independent analog outputs (±10 V or 4–20 mA, depending on configuration)

- Primary Application: Drives LVDT feedback–based servo valves for liquid or gas fuel control

- Input Interface: Receives digital commands via ribbon cable from DTBC terminal board or main processor rack

- Diagnostic Features: Onboard LEDs for power and channel status; fault reporting via Mark V HMI

- Mounting: Plug-in PCB in Mark V core rack (commonly in core)

- Calibration: Requires periodic zero/span adjustment using onboard potentiometers or software offsets

- Compatibility: Mark V systems with G2-series hardware; firmware must align with turbine application code

System Role and Downtime Impact

The DS200FSAAG2ABA is a pivotal component in the fuel control loop of GE heavy-duty gas turbines operating under Mark V control. It translates high-level fuel demand signals—derived from speed, temperature, and load references—into accurate analog voltages that position fuel control valves via electro-hydraulic servos. Any malfunction (e.g., signal drift, channel failure, or output saturation) can cause unstable combustion, flameout, over-firing, or inability to synchronize to grid. In redundant configurations, a single FSA board failure may force the system into degraded mode; in non-redundant setups, it can trigger an immediate turbine trip. Replacement requires system shutdown, careful calibration against LVDT feedback, and validation through fuel stroke reference (FSR) sweeps—processes heavily dependent on spare part availability and technician expertise.

Reliability Analysis and Common Failure Modes

Despite robust industrial construction, the DS200FSAAG2ABA is susceptible to performance degradation due to its reliance on precision analog components. The most frequent failure modes include drift in digital-to-analog converter (DAC) circuits or output op-amps, leading to incorrect valve positioning and control instability. Electrolytic capacitors in the local power filtering network often degrade over time, introducing noise or ripple into the analog output—particularly problematic during transient operations like startup or load changes. Additionally, repeated thermal cycling can cause solder fatigue around high-pin-count connectors, resulting in intermittent signal loss. A known vulnerability is sensitivity to ground loops or EMI from nearby power cabling, which may induce offset errors undetectable without oscilloscope verification. Preventive maintenance should include periodic calibration checks, visual inspection for capacitor bulging, cleaning of connector contacts, and monitoring of FSR vs. actual valve position trends in historical data.

DS200FSAAG2ABA GE

Lifecycle Status and Migration Strategy

GE has officially discontinued the DS200FSAAG2ABA as part of the Mark V platform’s obsolescence roadmap. No new units are available through official distribution, and technical support is limited to legacy service contracts with diminishing engineering resources. Continued operation poses significant operational risk: untested surplus modules may exhibit latent faults, counterfeit boards may lack proper calibration, and compatibility issues with existing firmware can lead to erratic behavior. Short-term mitigation includes sourcing units from certified vendors with full functional test reports (including channel accuracy and noise performance), implementing pre-installation burn-in procedures, and maintaining a small inventory of verified spares. The strategic long-term path is migration to the Mark VIe control system, which replaces discrete analog output boards like the FSAA with integrated, high-resolution I/O modules (e.g., IO Pack-based analog outputs) managed through the unified ToolboxST environment. This transition eliminates obsolete hardware dependencies, enhances diagnostic granularity, and ensures ongoing cybersecurity and regulatory compliance—critical for asset owners seeking to extend the life of their turbine fleets while reducing lifecycle risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: