Description

Key Technical Specifications (For Spare Part Verification)

- Product Model: DS200FSAAG1ABA

- Manufacturer: General Electric (GE)

- System Family: Mark V Turbine Control System

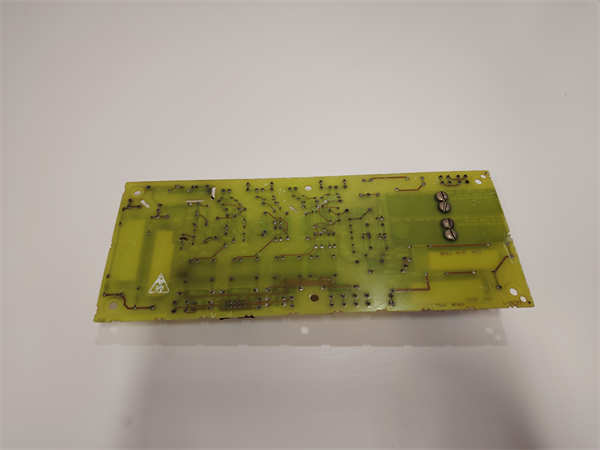

- Board Type: Field Supply Amplifier (FSAA), Revision G1, Variant ABA

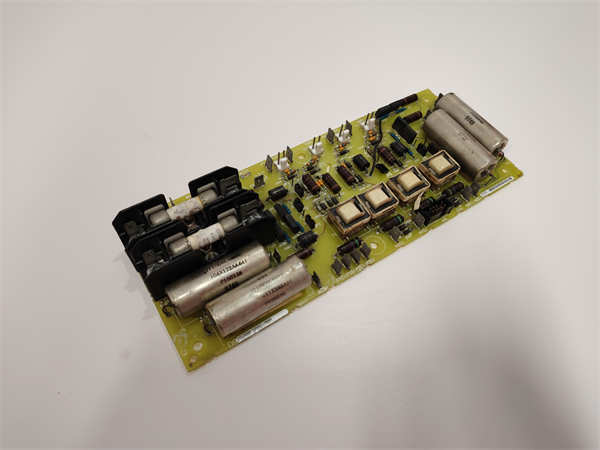

- Primary Function: Signal conditioning and isolation for generator field voltage and current feedback from the excitation system

- Input Signals: ±150 V DC field voltage, 0–10 A DC field current (via shunt or CT)

- Output Interface: Analog signals to VCMI/VCMA boards in the Mark V I/O core

- Power Supply: +5 V, ±15 V DC from PCCA backplane

- Mounting: Vertical card-cage mount in Mark V or core chassis

- Connector Types: AMPMODU backplane connector and terminal block for field wiring

- Diagnostic Features: Test points for calibration; no active LEDs on most G1 revisions

- Compatibility: Must match exact revision (G1) and suffix (ABA); not interchangeable with later FSAAG2+ variants

System Role and Downtime Impact

The DS200FSAAG1ABA is a key analog interface between the high-power excitation system and the Mark V’s digital control logic. It provides accurate, isolated measurement of generator field voltage and current—data essential for the automatic voltage regulator (AVR) function. If this board fails or drifts out of calibration, the Mark V receives incorrect field feedback, which can cause over-excitation, under-voltage trips, or unstable reactive power sharing. In grid-connected plants, such anomalies may trigger protective relays and result in a forced turbine trip. Because the FSAA is typically not redundant, its failure directly compromises excitation control integrity, often leading to an immediate unit derate or full outage until replaced.

Reliability Analysis and Common Failure Modes

The FSAA operates in a high-noise electrical environment and is subject to long-term component aging. The most common failure mechanisms include drift in precision operational amplifiers and voltage reference ICs due to thermal stress, leading to inaccurate signal scaling. Electrolytic capacitors in the filtering stages degrade over time (typically after 10–15 years), causing signal ripple or offset errors. Additionally, the analog circuitry is sensitive to ground loops or transient surges from the exciter field wiring, which can damage input protection diodes or isolation barriers. Environmental factors like dust accumulation and elevated cabinet temperature accelerate component wear. Recommended preventive maintenance includes annual calibration verification using a precision multimeter, visual inspection for capacitor leakage or discoloration, ensuring clean and tight field wiring terminations, and confirming proper grounding of the excitation system shield.

DS200FSAAG1ABA GE

Lifecycle Status and Migration Strategy

GE has discontinued the DS200FSAAG1ABA as part of the Mark V platform’s obsolescence roadmap. No new units are available, and GE no longer offers repair services, calibration support, or replacement documentation for this G1 revision. Continued reliance on this board poses significant operational risk: spare parts are scarce, often sourced from decommissioned units, and may lack traceable calibration history. As a temporary measure, facilities may retain tested spares and perform periodic bench calibration checks. However, the long-term solution is migration to a modern control architecture. GE’s recommended path is upgrading to the Mark VIe platform, which integrates field measurement directly into digital I/O modules with self-calibrating ADCs and eliminates discrete analog interface cards like the FSAA. This transition requires replacing the excitation interface hardware, updating control logic in ToolboxST, and re-commissioning AVR parameters—but delivers improved accuracy, diagnostic visibility, and compliance with modern cybersecurity standards such as IEC 62443.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: