Description

Key Technical Specifications (For Spare Parts Verification)

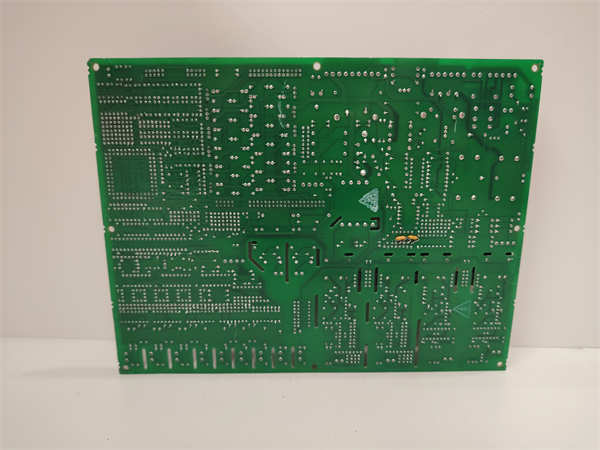

- Product Model: DS200DCFBG1BNC

- Manufacturer: General Electric (GE Power / GE Vernova)

- System Family: Mark V Speedtronic Turbine Control System

- Board Type: DC Feedback Board (DCFB), G1 revision, BNC variant

- Input Types: Supports multiple analog input types per channel—typically LVDT (AC-excited position sensors), RTD (Pt100), and 4–20 mA current loops

- Channel Count: Usually 8–12 channels, configurable via jumpers or firmware

- Signal Conditioning: Onboard excitation for LVDTs, precision amplification, filtering, and A/D conversion

- Output Interface: Digital data transmitted via ribbon cable to DTBC terminal board and main processors

- Diagnostic Features: Channel-level fault detection (open circuit, short, out-of-range); status LEDs

- Mounting: Plug-in PCB in Mark V core rack (commonly in or core)

- Calibration: Requires periodic zero/span adjustments using onboard potentiometers or software offsets

- Compatibility: Mark V systems with G1-series hardware; must match application-specific PROM/firmware

System Role and Downtime Impact

The DS200DCFBG1BNC serves as a primary analog input gateway in the GE Mark V control system, converting raw field sensor signals into digitized data used for real-time turbine control and protection. It commonly processes feedback from critical components such as inlet guide vanes (IGVs), fuel valve positions (via LVDTs), bearing temperatures (via RTDs), and lube oil pressure transmitters. Loss or corruption of these signals can lead to incorrect control actions—such as improper IGV scheduling, false high-exhaust-temperature trips, or undetected bearing overheating. In safety-critical loops, a failed DCFB channel may trigger a turbine trip or prevent startup. Because the board is not hot-swappable and often lacks full channel redundancy, replacement typically requires a controlled shutdown, followed by recalibration and loop validation—processes significantly delayed by spare parts scarcity.

Reliability Analysis and Common Failure Modes

The DS200DCFBG1BNC relies on precision analog circuitry that is vulnerable to long-term degradation. The most common failure modes include drift in instrumentation amplifiers or reference voltage sources, leading to inaccurate signal scaling—particularly problematic for LVDT feedback where small errors affect fuel positioning. Electrolytic capacitors in power and signal paths frequently dry out after 20+ years of service, introducing noise or causing intermittent channel dropouts. Additionally, the board’s LVDT excitation circuitry is sensitive to load imbalances or wiring faults, which can overload driver components and cause cascading failures. A design limitation is the shared excitation source across multiple LVDT channels; a short in one field device can disable several inputs. For preventive maintenance, technicians should perform periodic loop checks, verify excitation voltage levels, inspect for capacitor bulging, clean dust from ventilation areas, and monitor diagnostic logs for recurring “minor faults” that may indicate early component stress.

GE DS200DCFBG1BNC

Lifecycle Status and Migration Strategy

GE has formally discontinued the DS200DCFBG1BNC as part of the Mark V platform’s end-of-life cycle. No new units are available through official channels, and engineering support is restricted to legacy service agreements with minimal troubleshooting depth. Continued use entails substantial operational risk: untested surplus modules may fail under load, counterfeit units may lack proper calibration traceability, and firmware mismatches can cause signal interpretation errors. Short-term mitigation includes sourcing boards from certified vendors with full functional test reports (including LVDT simulation and RTD accuracy verification), implementing pre-installation burn-in testing, and maintaining a small inventory of verified spares. The strategic long-term solution is migration to the Mark VIe control platform, which replaces discrete boards like the DCFB with modular, high-density I/O packs featuring built-in diagnostics, digital sensor support (e.g., HART, Foundation Fieldbus), and seamless integration with ToolboxST. This transition eliminates obsolete hardware dependencies, improves measurement accuracy, and ensures ongoing access to cybersecurity updates and regulatory compliance support—critical for extending the reliable service life of aging turbine assets.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: