Description

Key Technical Specifications (For Spare Part Verification)

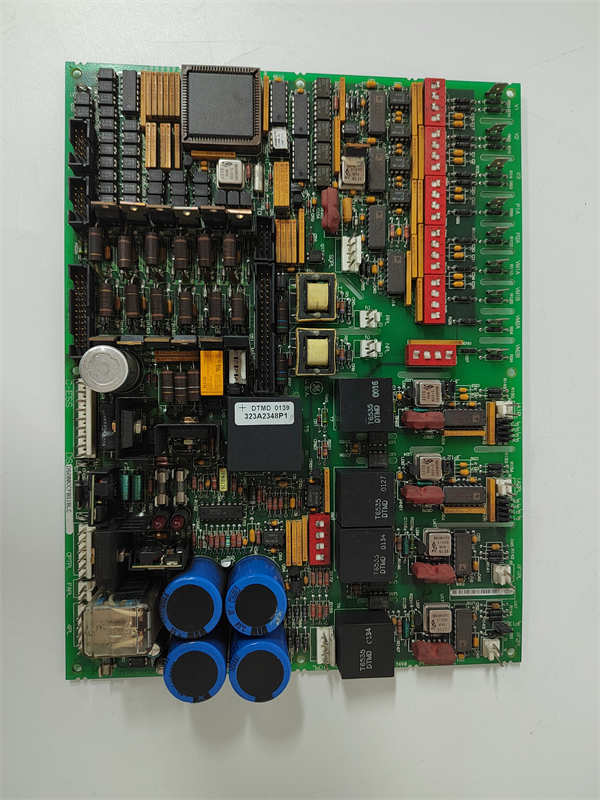

- Product Model: DS200DCFBG1BLC

- Manufacturer: General Electric (GE Power / GE Digital)

- System Family: Mark V / Mark VI Turbine Control System

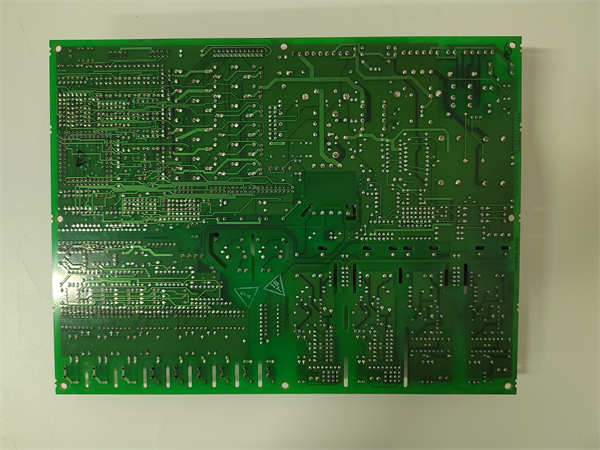

- Board Type: Printed Circuit Assembly (PCA) – plug-in module for core control rack

- Primary Functions:

- Distribution of ±15V, +24V, and +5V DC power rails to I/O modules

- Interface to field devices (relays, contactors, solenoids)

- Excitation system enable/disable signaling

- Breaker close/trip command handling

- Status feedback from auxiliary systems

- Connectors: Multiple high-density ribbon and terminal connectors for backplane and external wiring

- Indicators: LEDs for power status, fuse faults, and output activity

- Redundancy: Typically used in triple-redundant Mark V configurations (R, S, T cores)

- Firmware/Config: Hardware-configured via jumpers and DIP switches; no onboard software

System Role and Downtime Impact

The DS200DCFBG1BLC is a foundational hardware interface in GE’s Mark V distributed control system—widely deployed in gas and steam turbines for power generation since the 1990s. It acts as the bridge between the central control processors (e.g., TCEA/TCEB cards) and critical field equipment such as generator breakers, excitation systems, lube oil pumps, and fuel valves.

In a triple-modular redundant (TMR) Mark V architecture, three identical DCFB boards operate in parallel—one per control core. While redundancy provides fault tolerance, failure of all three (or degradation in two) can lead to loss of turbine control, forcing an emergency shutdown or preventing startup. Even a single failed DCFB can trigger alarms, degrade redundancy, and complicate troubleshooting during outages.

Because this board handles high-current relay drivers and power distribution, its failure often cascades—causing blown fuses, damaged field devices, or misoperation of safety interlocks. In plants still operating on Mark V (common in emerging markets or legacy fleets), unplanned DCFB failure can result in days or weeks of downtime due to scarce spares and complex diagnostics.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the DS200DCFBG1BLC is vulnerable to several age-related issues:

- Electrolytic capacitor degradation: Causes voltage ripple, power instability, or complete loss of DC rails—especially on ±15V lines powering analog I/O.

- Relay driver transistor failure: Due to inductive kickback from field coils without adequate snubbing, leading to stuck outputs or open circuits.

- Connector corrosion or cold solder joints: Exacerbated by thermal cycling in turbine control rooms; results in intermittent signals or communication errors.

- Fuse holder fatigue: Repeated thermal expansion can loosen fuse contacts, causing high-resistance faults that mimic field device failures.

- PCB trace delamination: From prolonged exposure to heat or moisture, particularly near power regulators.

Preventive measures include:

- Regular infrared thermography of the board during operation

- Verifying DC rail voltages under load

- Inspecting fuse integrity and connector seating

- Maintaining clean, dry, and temperature-controlled control enclosures

GE DS200DCFBG1BLC

Lifecycle Status and Migration Strategy

GE has discontinued the Mark V platform, including the DS200DCFBG1BLC, with official support now limited to extended service agreements through Baker Hughes (which acquired GE’s legacy turbine business). Genuine new-old-stock (NOS) units are virtually unavailable; most spares come from decommissioned turbines or third-party refurbishers—often without full functional testing.

Continued reliance on this hardware carries significant operational risk. The recommended long-term strategy is migration to Mark VIe or Mark VIe X, GE’s modern turbine control platform based on PACSystems RX3i controllers and IEC 61850 networking. This upgrade involves:

- Replacing the entire control core (including DCFB, TCEA, IO cards)

- Rewiring field connections to new I/O modules

- Recompiling or re-engineering control logic in Proficy Machine Edition

- Retraining operations and maintenance staff

While capital-intensive, migration eliminates obsolescence risk, improves cybersecurity posture, enables remote diagnostics, and extends turbine life by 15–20 years. For facilities not ready for full replacement, strategic sparing (acquiring 2–3 tested units) and board-level repair contracts with specialized vendors offer interim mitigation—but do not address underlying architectural limitations.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: