Description

Technical Specifications (For Spare Part Verification)

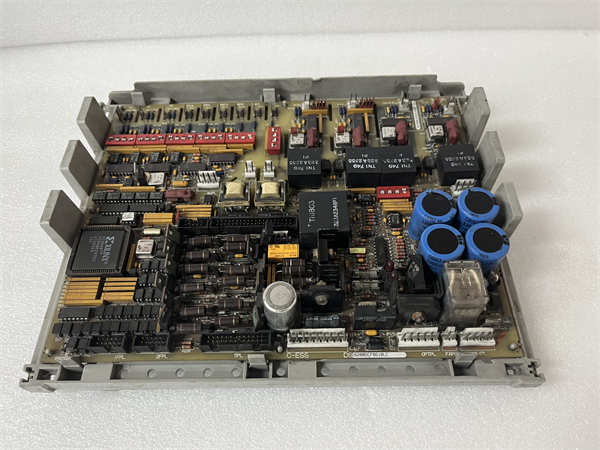

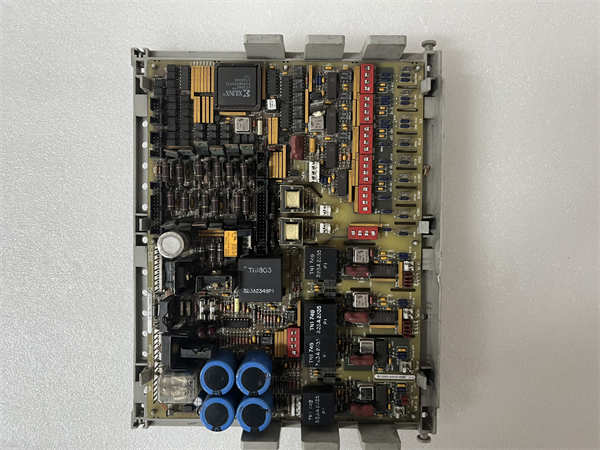

- Product Model: DS200DCFBG1BLC

- Manufacturer: General Electric

- System Family: Mark V Turbine Control System (typically for Frame 5–7 gas turbines or steam units)

- Board Type: DCFB (DC Field Bridge) interface card

- Function: Interfaces between Mark V core processors (PTBA/TCEA) and the static excitation system; provides analog output to gate drive circuits and reads back field current/voltage

- Connector Types: Multiple AMP/TE connectors for field wiring, backplane, and exciter communication

- Key Components: Includes precision op-amps, isolated analog isolators, relay drivers, and status LEDs

- Firmware/Revision: Must match existing system revision (e.g., “G1BLC” indicates specific hardware/firmware variant)

- Mounting: Slot-mounted in Mark V core rack (typically alongside TCDA, TCEA, and PTBA boards)

- Diagnostic Indicators: Onboard LEDs for power, excitation enable, and fault status

- Calibration: Requires post-installation calibration of field current feedback loop using GE Toolbox software

System Role and Downtime Impact

The DS200DCFBG1BLC is a critical analog I/O board within the GE Mark V control architecture, serving as the electrical bridge between the digital control logic and the high-power excitation system. It translates digital setpoints from the turbine controller into analog signals that regulate thyristor firing angles in the exciter, thereby controlling generator terminal voltage and VAR output.

If this board fails—due to component drift, power supply fault, or signal corruption—the excitation system may default to manual mode, lose regulation, or shut down entirely. In grid-connected operations, this typically triggers an automatic turbine trip to prevent equipment damage or instability. Because the Mark V system lacks full redundancy at the DCFB level in many legacy installations, a single board failure can force an unplanned outage. Recovery requires not only board replacement but also revalidation of the entire excitation control loop, often extending downtime by 24–72 hours.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the DS200DCFBG1BLC is susceptible to age-related degradation due to its mixed-signal architecture and exposure to electrical noise in power plant environments. The most common failure modes include:

- Drift in analog isolation amplifiers, causing inaccurate field current feedback and unstable voltage regulation

- Failure of surface-mount electrolytic capacitors in local power regulators, leading to intermittent resets or output latch-up

- Corrosion or oxidation on edge connectors, disrupting communication with the Mark V backplane

- Relay contact wear on the excitation enable/disable circuit, resulting in false trip commands

A key design vulnerability is the lack of onboard self-diagnostics for analog signal paths—errors often manifest only as process-level instability, not board-level faults. Additionally, the board is sensitive to ground loops and EMI from nearby high-current cabling, especially if shielding integrity has degraded over time.

Preventive maintenance recommendations:

- Perform annual loop calibration checks using GE’s DOS-based Toolbox software

- Inspect for bulging or leaking capacitors during routine cabinet inspections

- Verify connector seating torque and clean with contact enhancer during outages

- Monitor excitation system logs for unexplained VAR swings or manual-mode transitions

GE DS200DCFBG1BLC

Lifecycle Status and Migration Strategy

GE officially discontinued the Mark V platform over a decade ago, with the DS200DCFBG1BLC no longer in production. While some service depots retain refurbished units, these lack factory traceability and may have undergone undocumented repairs. Continued reliance on this board introduces significant operational and compliance risk, particularly under NERC PRC-002/004 requirements for protection system reliability.

As a temporary measure, operators may:

- Secure multiple tested spares with full calibration records

- Implement external excitation monitoring (e.g., standalone VAR controllers) as a backup layer

- Restrict operation to base-load conditions to minimize excitation cycling stress

For long-term sustainability, GE Vernova recommends migrating to the Mark VIe platform. The functional equivalent involves:

- Replacing the entire Mark V core with a Mark VIe controller (including I/O terminal boards)

- Integrating the existing excitation system via TMR-compatible DCFG or DCFD modules

- Recommissioning the excitation control logic in ToolboxST, which offers enhanced diagnostics and cybersecurity features

This migration requires extensive engineering, FAT/SAT testing, and coordination with grid operators. Given the DCFB’s role in generator stability, treating it as a high-priority obsolescence item—not a maintainable asset—is essential for ensuring decades-long operational continuity.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: