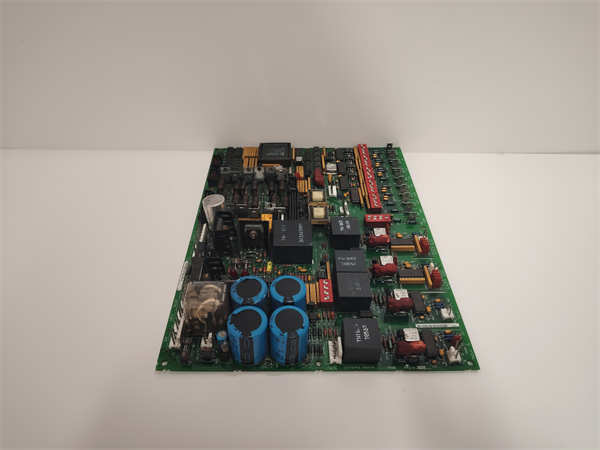

Description

Key Technical Specifications (For Spare Part Verification)

- Product Model: DS200DCFBG1BLC

- Manufacturer: General Electric (GE)

- System Family: Mark V Turbine Control System

- Board Type: DC Feedback Board (DCFB), Revision G1, Variant BLC

- Primary Function: Signal conditioning, scaling, and isolation of generator field voltage (up to ±500 V DC) and field current (via shunt)

- Output Signals: Buffered ±10 V analog outputs to VCMI or VCMA I/O boards

- Power Supply: +5 V, ±15 V DC from PCCA backplane

- Mounting: Vertical insertion in Mark V or core chassis

- Connector Types: AMPMODU backplane connector and screw-terminal block for field wiring

- Isolation: Optical and transformer-based isolation between high-voltage field side and low-voltage control side

- Calibration: Adjustable potentiometers for voltage and current gain/offset (requires precision tools)

- Compatibility: Specific to G1 revision and BLC variant; not interchangeable with DCFBG2 or other suffixes

System Role and Downtime Impact

The DS200DCFBG1BLC is a critical analog interface in the excitation feedback loop of GE heavy-duty gas or steam turbines. It ensures the Mark V control system receives precise, noise-immune measurements of generator field voltage and current—data directly used by the automatic voltage regulator (AVR) to maintain terminal voltage within tolerance. A malfunction—such as signal drift, loss of isolation, or complete failure—can cause the AVR to over- or under-excite the generator, potentially triggering protective relays (e.g., V/Hz or overvoltage trips) and resulting in an unplanned turbine shutdown. Because this board lacks redundancy in most Mark V configurations, its failure constitutes a single point of vulnerability with direct consequences for grid stability and plant revenue.

Reliability Analysis and Common Failure Modes

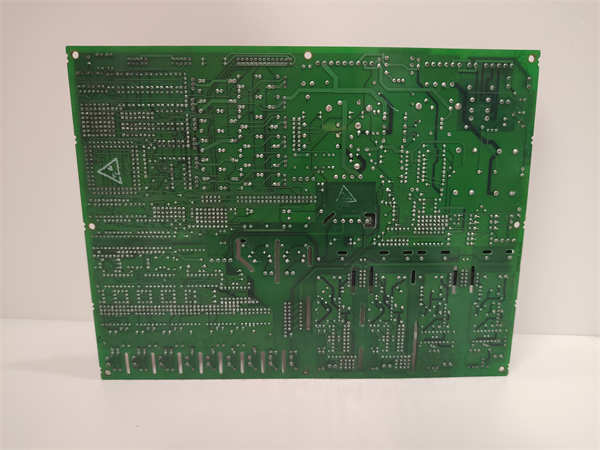

The DCFB operates under continuous exposure to high common-mode voltages and electrical transients, making it prone to long-term degradation. The most frequent failure modes include drift in precision resistor networks and instrumentation amplifiers due to thermal cycling, leading to inaccurate scaling of field signals. Electrolytic and tantalum capacitors in filtering stages often degrade after 10–15 years, introducing noise or offset errors. Additionally, the high-voltage isolation barriers (optocouplers and isolation amplifiers) can weaken over time, risking ground faults or signal corruption. Environmental stressors such as dust, humidity, and elevated cabinet temperatures accelerate component aging. Recommended preventive actions include annual calibration verification using calibrated DC sources, visual inspection for capacitor bulging or PCB discoloration, ensuring clean and secure field wiring connections, and maintaining cabinet temperature below 40°C with functional filtration.

DS200DCFBG1BLC GE

Lifecycle Status and Migration Strategy

GE has formally discontinued the DS200DCFBG1BLC as part of the Mark V platform’s end-of-life declaration. No new units are manufactured, and GE no longer provides repair services, calibration certificates, or technical documentation for this G1 revision. Continued use relies entirely on the secondary market, where available units are often untested, lack traceability, and command premium pricing. As a short-term mitigation, operators may stock “golden” spares stored in controlled environments and perform periodic bench testing. However, the only sustainable path forward is migration to a modern digital control system. GE’s strategic replacement is the Mark VIe, which replaces discrete analog boards like the DCFB with integrated, self-calibrating digital I/O modules that sample field signals directly via high-resolution ADCs. This upgrade eliminates analog drift concerns, enhances diagnostic capabilities, and supports secure remote monitoring—aligning the plant with current cybersecurity and operational excellence standards. While requiring re-engineering of control logic and I/O architecture, the transition significantly reduces long-term obsolescence risk and maintenance burden.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: