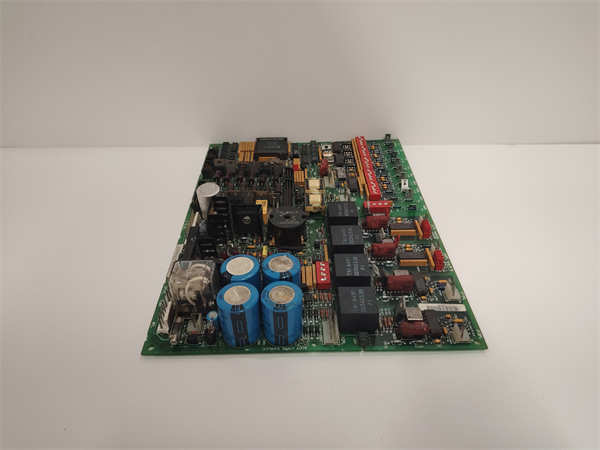

Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: DS200DCFBG1BJB

- Manufacturer: General Electric (GE)

- System Family: Mark V Turbine Control System (Triple Modular Redundant – TMR)

- Module Type: DC Feedback Board (DCFB)

- Primary Function: Conditioning and digitizing analog feedback inputs (e.g., servo position, pressure, temperature)

- Input Channels: Typically 8–16 differential analog inputs (varies by configuration)

- Signal Range: ±10 V DC standard; compatible with LVDT, RVDT, and 4–20 mA (via external shunt)

- Backplane Interface: Connects to Mark V core rack via DIN 41612 connectors

- Diagnostic Features: Onboard LEDs for power and channel activity; fault reporting via PCCA communication

- Firmware Dependency: Requires alignment with system software version (CSP/CDB)

- Operating Environment: Industrial control room (0°C to 50°C, non-condensing humidity)

System Role and Downtime Impact

The DS200DCFBG1BJB is a key analog input interface in the GE Mark V control system, responsible for acquiring real-time feedback from critical turbine actuators and sensors—such as fuel valve position, inlet guide vane angle, or bearing pressure. These signals are essential for closed-loop control during startup, loading, and speed regulation. In the TMR architecture, each DCFB operates in triplicate (one per lane), and discrepancies between lanes trigger voting faults that can escalate to turbine trips if unresolved. A failed DCFB may cause erratic control behavior (e.g., hunting servos), false alarms, or—in worst cases—loss of protective response during abnormal conditions. Because analog feedback integrity directly affects combustion stability and mechanical stress, DCFB reliability is tightly linked to both safety and asset longevity.

Reliability Analysis and Common Failure Modes

The DS200DCFBG1BJB is susceptible to several age-related failure mechanisms due to its mixed-signal design and decades-long deployment in demanding environments. Common issues include:

- Operational amplifier drift or failure in signal conditioning circuits, leading to offset errors or signal clipping

- Reference voltage instability from aging voltage regulators or capacitors, causing calibration shifts

- Connector corrosion or cold solder joints, especially on high-density backplane pins, resulting in intermittent channels

- Electromagnetic interference (EMI) susceptibility, exacerbated by degraded shielding or grounding over time

A notable design limitation is the lack of per-channel self-diagnostics; most faults are only detected when voting mismatches occur across TMR lanes. Additionally, the board relies on obsolete surface-mount components that are no longer available, complicating repairs.

Recommended preventive maintenance:

- Perform annual calibration checks using simulated inputs and compare across all three TMR lanes

- Inspect for discoloration, bulging capacitors, or burnt smell near analog front-end circuits

- Verify proper grounding of field wiring shields to minimize noise-induced errors

- Ensure consistent firmware and hardware revision levels across all DCFB modules in the rack

- Store spare units in ESD-safe, dry, climate-controlled conditions

DS200DCFBG1BJB GE

Lifecycle Status and Migration Strategy

GE has officially discontinued the DS200DCFBG1BJB as part of the Mark V platform’s end-of-life roadmap. No new units are manufactured or stocked by GE Vernova. Remaining availability is restricted to used, refurbished, or salvaged inventory—often sold at steep premiums (3–5× original cost) with no performance guarantee. Software support through GE Toolbox is minimal, and technical documentation is increasingly difficult to access.

Interim risk-mitigation options include:

- Stockpiling tested, matched spares from trusted vendors

- Partnering with specialized firms for component-level repair and recalibration

- Implementing external signal validation (e.g., redundant transmitters with independent monitoring)

The strategic path forward is migration to the Mark VIe or Mark VIeS platform, which replaces discrete I/O boards like the DCFB with modular, Ethernet-based I/O processors featuring built-in diagnostics, hot-swap capability, and compliance with modern cybersecurity standards. However, this transition requires comprehensive re-engineering of I/O wiring, logic recompilation, functional safety revalidation, and operator training—making it a major capital initiative best scheduled during planned turbine outages. Delaying migration increases exposure to unplanned downtime driven by irreplaceable hardware failures.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: