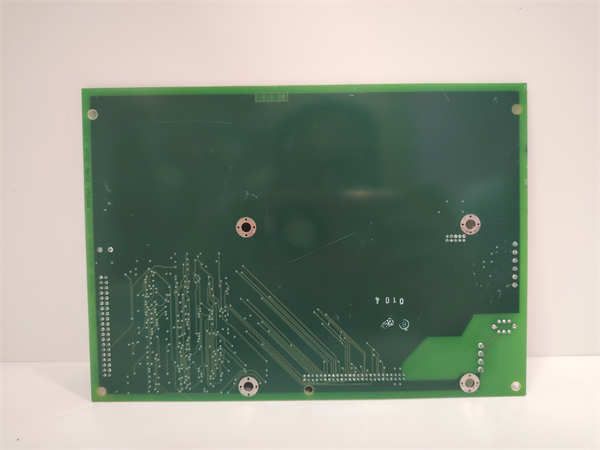

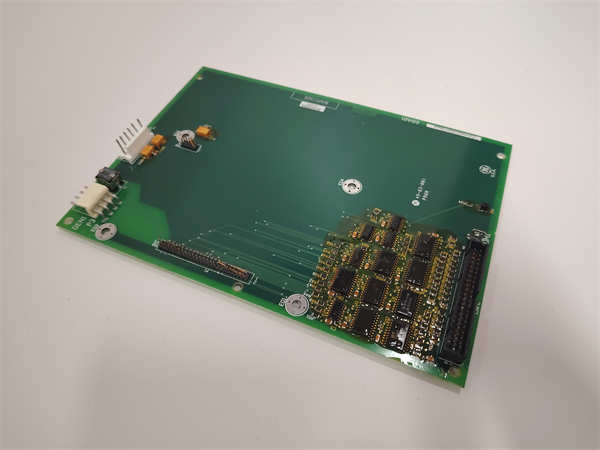

Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: DS200ADGIH1AAA

- Manufacturer: General Electric (GE Power / GE Vernova)

- System Family: Mark V Speedtronic Turbine Control System

- Board Type: Analog/Digital Gateway Interface (ADGI), H1 revision, AAA variant

- I/O Types Supported: Mixed-signal—includes 4–20 mA, thermocouples, RTDs, contact inputs, and low-voltage digital signals

- Channel Capacity: Typically 16–24 channels, configurable via hardware jumpers or software mapping

- Signal Conditioning: Onboard filtering, isolation, amplification, and A/D conversion for analog inputs; debounce and opto-isolation for digital inputs

- Communication Interface: Connects to DTBC terminal boards and main processor racks via multi-conductor ribbon cables

- Diagnostic Features: Channel fault detection (open circuit, short, out-of-range), status LEDs, error reporting to Mark V HMI

- Mounting: Plug-in PCB module in Mark V core rack (commonly in or core)

- Power Supply: +5 V, ±15 V from Mark V backplane

- Compatibility: Mark V systems with H1-series hardware; requires alignment with application-specific firmware

System Role and Downtime Impact

The DS200ADGIH1AAA functions as a versatile I/O concentrator in the GE Mark V architecture, bridging diverse field instruments—such as lube oil pressure transmitters, bearing temperature sensors, auxiliary pump status contacts, and fire detection switches—to the triple-modular redundant control cores. It ensures signal fidelity before data is processed by the main controllers for logic execution, alarming, or protective actions. Failure of this board can result in loss of multiple non-redundant I/O points simultaneously, potentially disabling critical alarms, causing false trips, or masking developing equipment faults (e.g., rising bearing temperature). While not always part of the primary fuel or speed control loop, its role in auxiliary and protection systems makes it essential for safe, compliant operation. Replacement requires system de-energization, re-mapping of I/O assignments, and comprehensive loop checks—activities heavily constrained by spare parts availability and calibration complexity.

Reliability Analysis and Common Failure Modes

The DS200ADGIH1AAA integrates both analog and digital circuitry, exposing it to multiple failure vectors over time. The most prevalent issues include degradation of precision resistors and op-amps in analog input paths, leading to signal offset or gain errors—particularly noticeable in temperature or pressure readings. Electrolytic capacitors in local power regulation circuits commonly dry out after decades of service, causing intermittent resets or noisy outputs. On the digital side, optocouplers used for contact isolation may fail open or short, resulting in stuck-on or stuck-off states that mimic field device faults. Additionally, repeated thermal cycling can induce micro-cracks in solder joints around high-density connectors, creating intermittent communication with the DTBC interface. A design limitation is the lack of per-channel redundancy; a single component failure can disable an entire I/O group. Preventive maintenance should include periodic calibration verification, visual inspection for capacitor leakage or bulging, cleaning of edge connectors, and trend analysis of I/O values for early drift detection.

GE DS200ADGIH1AAA

Lifecycle Status and Migration Strategy

GE has officially discontinued the DS200ADGIH1AAA as part of the broader obsolescence of the Mark V platform. No new units are available through authorized channels, and technical support is limited to legacy service contracts with minimal engineering depth. Continued reliance on this hardware carries significant risk: untested surplus modules may exhibit latent faults under load, counterfeit units may lack proper isolation ratings, and firmware mismatches can cause I/O misinterpretation. Short-term mitigation includes sourcing from certified vendors with full functional test documentation (including analog accuracy and digital state validation), implementing pre-installation burn-in procedures, and maintaining a small inventory of verified spares. The strategic long-term path is migration to the Mark VIe control system, which replaces discrete gateway boards like the ADGI with scalable, intelligent I/O packs featuring built-in diagnostics, digital communication (e.g., HART over 4–20 mA), and seamless integration with the unified ToolboxST engineering environment. This transition eliminates obsolete component dependencies, enhances data reliability, and ensures ongoing access to cybersecurity updates and regulatory compliance support—essential for operators managing aging turbine fleets in a modern operational landscape.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: