Description

Key Technical Specifications (For Spare Verification)

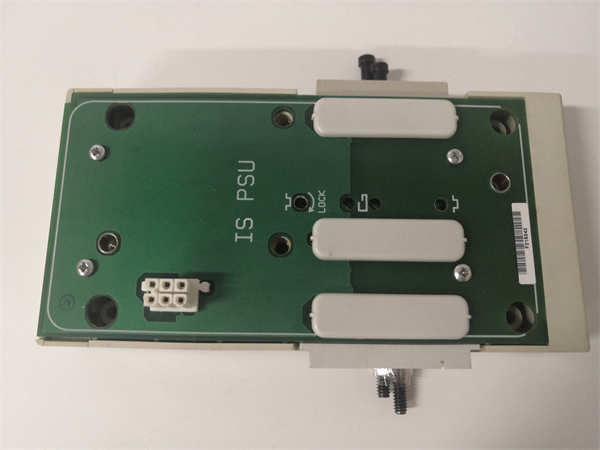

- Product Model: 8724-CA-PS

- Manufacturer: GE Power (formerly GE Energy)

- System Family: Mark VIe Turbine Control Platform

- Input Voltage: 100–240 VAC, 50/60 Hz (auto-ranging)

- Output Rating: 24 VDC ±2%, 10 A continuous (dual-redundant capable)

- Redundancy Support: Hot-swappable with parallel unit via OR-ing diodes

- Mounting Type: Backplane-mounted in Mark VIe I/O core rack (typically slot 1 or 2)

- Diagnostic Features: LED indicators for AC OK, DC OK, and fault status; communicates health via IOBUS to controller

- Connector Type: Dedicated high-density backplane connector (non-standard, proprietary to Mark VIe)

- Operating Temperature: 0°C to +60°C ambient

GE 8724-CA-PS

System Role and Downtime Impact

The GE 8724-CA-PS is a foundational power component within the Mark VIe distributed control architecture used in gas and steam turbines. It resides in the core I/O processor rack and delivers conditioned 24 VDC to all local I/O modules, terminal boards, and communication interfaces. While the system supports dual power supplies for redundancy, a single-unit failure under degraded conditions (e.g., one supply already offline) will cause a complete loss of I/O communication, leading to an automatic turbine trip per safety logic. In non-redundant configurations—still found in auxiliary or older retrofitted units—failure results in immediate control system blackout and unplanned outage. Given its role in mission-critical power generation assets, unavailability of this module directly translates to operational risk and potential revenue loss.

Reliability Analysis and Common Failure Modes

Although designed for industrial environments, the 8724-CA-PS exhibits predictable aging patterns due to its reliance on electrolytic capacitors and switching regulators. The most frequent failure mode is gradual output voltage droop caused by dried-out bulk capacitors, often manifesting as intermittent I/O faults or spontaneous reboots of connected controllers. Secondary issues include failed inrush current limiters (leading to blown fuses on startup) and corrosion on backplane connectors in high-humidity installations. A known design vulnerability is the lack of field-replaceable internal components—repair requires board-level expertise.

Preventive maintenance should focus on thermal imaging during operation to detect abnormal heating (indicative of capacitor ESR rise), periodic verification of output voltage under load using a calibrated meter, and inspection of ventilation paths around the I/O rack. Facilities with extended uptime should consider proactive replacement of units exceeding 10 years of service, even if currently functional.

GE 8724-CA-PS

Lifecycle Status and Migration Strategy

GE officially discontinued the 8724-CA-PS as part of the broader Mark VIe legacy support phase-out. No direct “drop-in” replacement exists from GE; new builds now use the Mark VIeS or Mark VIe+ platforms with updated power architectures. Continued use carries significant risks: genuine spare availability is constrained to certified surplus channels, counterfeit units have been reported in open markets, and GE no longer provides repair services or firmware updates.

As a temporary measure, operators may source tested, functionally verified units from specialized industrial asset support providers who perform full-load burn-in and output stability validation. Board-level repair by third-party specialists is possible but requires access to original schematics and component-level diagnostics.

For long-term sustainability, GE’s recommended migration path is a staged upgrade to Mark VIeS, which uses the newer 8724-DA-PS power module family. This transition necessitates rack hardware changes, I/O retermination, and partial application revalidation—but eliminates dependency on obsolete power components while enhancing cybersecurity and remote diagnostics capabilities. Until migration occurs, maintaining at least one verified spare per turbine is strongly advised.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: