Description

Key Technical Specifications (For Spare Parts Verification)

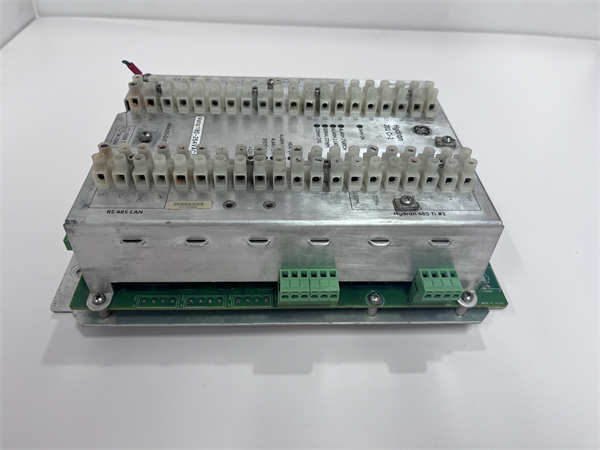

- Product Model: 201CI-1

- Manufacturer: General Electric (GE Fanuc Automation)

- System Family: GE Series One PLC

- Mounting Type: DIN rail or panel mount

- Input Power: Typically 120/240 VAC, 50/60 Hz (verify nameplate)

- I/O Capacity: Supports up to 128 I/O points via local expansion modules

- Program Memory: Battery-backed RAM (approximately 1–2 KB)

- Communication Ports: RS-232/RS-422 for programming (compatible with IC600 series interface)

- Backplane Compatibility: Requires IC600-style or Series One chassis (slot-specific)

- Physical Dimensions: Approx. 150 x 120 x 80 mm (varies by revision)

System Role and Downtime Impact

The GE 201CI-1 functions as the central processor in GE Series One control systems, commonly installed in industrial equipment from the 1980s and 1990s, including material handling, water/wastewater facilities, and batch process machinery. It scans input modules, executes ladder logic, and updates outputs in a fixed cycle. Due to the integrated architecture of the Series One platform—where the CPU, power supply, and I/O are closely interdependent—a failure of the 201CI-1 typically halts all automated functions. In continuous operations, this can lead to unplanned production stoppages lasting several days if a verified spare is not immediately available, potentially affecting safety systems, regulatory compliance, and downstream processes.

Reliability Analysis and Common Failure Modes

Many 201CI-1 units continue operating due to their rugged construction and stable installation environments. However, aging components introduce significant reliability risks. The most frequent cause of failure is loss of program memory due to depletion of the backup battery (typically lithium or Ni-Cd), which is not monitored by the system. Without periodic replacement, even brief power interruptions can erase the control logic.

Secondary failure modes include electrolytic capacitor degradation in the internal power circuitry, leading to voltage droop, intermittent resets, or complete power loss. The serial communication drivers are also vulnerable to electrical transients, especially when connected to modern programming devices without proper isolation.

Design limitations exacerbate these issues: the module lacks non-volatile flash memory, real-time clock, watchdog timers, or modern EMI protection. Recommended preventive maintenance includes:

- Replacing the backup battery every 2–3 years regardless of system uptime

- Visual inspection for swollen capacitors, PCB discoloration, or terminal corrosion

- Ensuring clean, regulated AC power with transient voltage suppression

- Storing at least one fully programmed and tested spare unit in climate-controlled conditions

GE 201CI-1

Lifecycle Status and Migration Strategy

The GE 201CI-1 has been obsolete for over two decades. General Electric exited the low-end PLC market long ago, and no official support, repairs, or new units are available. Continued use entails high operational risk: genuine spare parts are extremely scarce, often salvaged from decommissioned sites, and may have unknown service history. Secondary market prices are unstable, and misrepresentation of condition or compatibility is common.

As an interim measure, some facilities rely on specialized third-party repair vendors capable of component-level refurbishment—such as replacing aging capacitors or upgrading battery circuits. Maintaining a validated spare remains critical for business continuity.

For sustainable operation, migration to a modern platform is strongly recommended. While no direct hardware replacement exists, typical upgrade paths include:

- GE VersaMax Micro: offers similar I/O density and simplified logic conversion

- Allen-Bradley MicroLogix 1400 or Siemens S7-1200: require full reprogramming but provide enhanced features and long-term support

- Hybrid retrofits: retain existing field wiring through I/O remapping gateways while replacing only the controller

Migration involves recovering original logic (if backups exist), reverse-engineering from documentation or physical wiring, and re-implementing in a current programming environment (e.g., Logix Designer or TIA Portal). Although requiring upfront investment, this approach eliminates obsolescence exposure and enables integration with modern SCADA, historian, and IIoT infrastructure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: