Description

Key Technical Specifications (For Spare Part Verification)

- Product Model: FEM100

- Manufacturer: Foxboro / Schneider Electric

- Order Code: P0973CA

- System Compatibility: Foxboro I/A Series DCS (e.g., CP60, CP80 stations with FBMI/FBME modules)

- Fieldbus Standard: Foundation Fieldbus H1 (IEC 61158)

- Communication Rate: 31.25 kbit/s

- Segment Capacity: Supports up to 32 field devices per H1 segment (power-limited)

- Redundancy Support: Yes – when used in pairs with redundant FBM24x/25x interface cards

- Power Supply: Powered via I/A Series backplane; provides intrinsically safe or non-IS power to field segment (via external power conditioner)

- Mounting: DIN-rail or rack-mounted in I/A Series I/O chassis

- Diagnostic Features: LEDs for module status, segment activity, fault, and redundancy state

System Role and Downtime Impact

The FEM100 serves as the critical bridge between the Foxboro I/A Series DCS and Foundation Fieldbus-enabled field devices. It handles protocol conversion, device scheduling, and real-time data exchange for pressure, temperature, flow, and valve control loops. In redundant configurations, a failed primary FEM100 should transfer responsibility to its standby unit—but if both fail, or redundancy is not implemented, all devices on the affected H1 segment become unreachable. This results in loss of process measurements, inability to command control valves, and potential loop failures. In continuous-process industries like refining or chemicals, this can trigger partial or full plant shutdowns, safety system overrides, or regulatory reporting events due to data loss.

Reliability Analysis and Common Failure Modes

Despite its industrial design, the FEM100 is susceptible to component aging typical of early-2000s communication modules. The most common failure mode is power regulation circuit degradation, particularly in the DC-DC converters that supply internal logic and segment isolation—leading to intermittent resets or complete dropout. Isolation barrier capacitor wear can compromise galvanic separation, increasing susceptibility to ground loops or surge damage from field wiring. Additionally, firmware corruption after unexpected power loss may render the module unresponsive, requiring reconfiguration or replacement.

A key vulnerability is its dependence on stable fieldbus power conditioners; voltage sags or overloads on the H1 segment can reflect back and damage the FEM100’s output stage. Units in high-humidity environments also show increased risk of PCB corrosion near terminal blocks.

Recommended preventive actions include:

- Monitoring I/A Series Station History for “FEM communication fault” or “segment offline” alarms

- Verifying redundancy handover during scheduled maintenance

- Ensuring proper grounding and surge protection on fieldbus trunk cables

- Maintaining spare FEM100 units with matching firmware and configuration backups

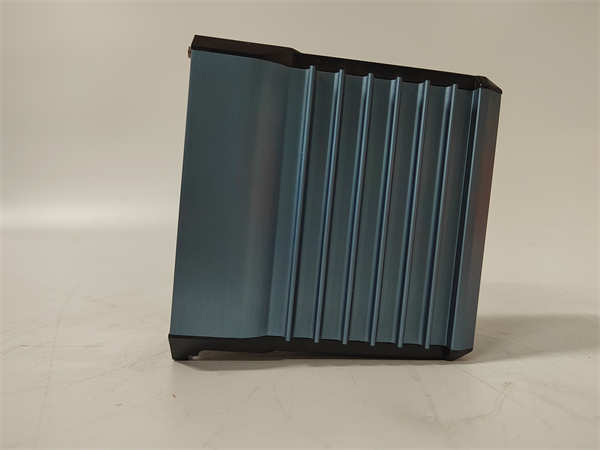

FOXBORO FEM100 P0973CA

Lifecycle Status and Migration Strategy

Schneider Electric has officially obsoleted the FEM100 as part of the legacy I/A Series product lifecycle plan. No new modules are manufactured, and factory repair or technical support is no longer available. Continued use increases exposure to extended downtime due to spare unavailability and declining expertise.

Short-term mitigation includes:

- Securing multiple tested spares with identical order codes and firmware revisions

- Validating full segment restore procedures using I/A Series Engineering Tools

- Documenting fieldbus device tags, VFD schedules, and segment topology

For long-term sustainability, Schneider Electric recommends migration to the Foxboro Evo DCS platform. While Evo does not natively support legacy FEM100 hardware, it offers modern alternatives such as:

- Integration of Foundation Fieldbus via FF-800 or FF-810 interface modules in Evo I/O architecture

- Use of protocol gateways to retain existing FF segments while connecting to Evo controllers

- Gradual replacement of FF devices with HART-over-Ethernet or WirelessHART instruments

Migration typically involves re-engineering the control strategy in Evo Control Studio, revalidating loop performance, and updating cybersecurity policies. Although capital-intensive, this path restores access to vendor support, software updates, and compliance with modern industrial standards—essential for facilities operating beyond 2030. A staged, segment-by-segment approach minimizes operational disruption while managing risk and cost.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: