Description

Technical Specifications (For Spare Parts Verification)

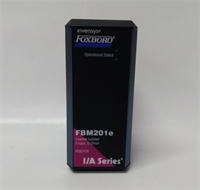

- Model: FBMSVL

- Manufacturer: The FOXBORO Company (Schneider Electric)

- System Family: I/A Series Distributed Control System (DCS)

- Module Type: Fieldbus Master Segment Interface (FF H1)

- Mounting: Designed for FBM207/208 carrier base in I/A Series I/O cabinets

- Fieldbus Standard: Foundation Fieldbus H1 per IEC 61158-2

- Communication Rate: 31.25 kbps

- Power Output: Intrinsically safe, typically 14–17 V DC at up to 350 mA per segment (FISCO-compliant)

- Isolation: Galvanic isolation between DCS backplane and fieldbus segment

- Physical Connectors: Dual M12 or screw-terminal field connections (depending on terminal block used)

- Diagnostic Indicators: LED status for power, communication, and fault conditions

- Redundancy: Supports redundant configuration when paired with dual FBM207 bases

System Role and Downtime Impact

The FOXBORO FBMSVL serves as the critical bridge between the I/A Series DCS and Foundation Fieldbus field instruments—such as pressure transmitters, valve positioners, and temperature sensors—in process industries. It supplies regulated, intrinsically safe power to the fieldbus segment while enabling bidirectional digital communication.

If the FBMSVL fails, the entire fieldbus segment it powers becomes non-operational. This can result in loss of control over multiple loops simultaneously. In a refinery or chemical plant, such a failure could trigger safety interlocks, force manual backup operations, or lead to unplanned shutdowns. Because the FBMSVL is often deployed in safety-critical or continuous-process applications, its reliability directly impacts plant availability and operational safety.

Reliability Analysis and Common Failure Modes

Although the FBMSVL contains no moving parts, its role in high-availability environments exposes it to several aging-related risks. Many units have operated for 15–20 years without replacement, increasing vulnerability to component degradation.

Common failure modes include:

- Electrolytic capacitor drying out or bulging on the internal power supply board, leading to unstable output voltage or complete power loss.

- Corrosion or oxidation on terminal blocks or backplane connectors, causing intermittent communication or signal dropouts.

- Damage to isolation barriers due to voltage surges from lightning or switching transients in the field wiring.

- Firmware corruption (in later revisions), though rare, can cause the module to hang during initialization.

Design weaknesses include dependence on aging power components with finite lifespans and limited onboard diagnostics—many faults manifest only as “segment offline” alarms without root-cause detail.

Preventive maintenance recommendations:

- Perform annual thermal imaging of the module and terminals to detect abnormal heating.

- Verify fieldbus signal quality using a Foundation Fieldbus analyzer during scheduled outages.

- Replace units proactively if installed prior to 2010, even if still functional.

- Ensure proper grounding and surge protection on fieldbus trunk cables to reduce stress on the module.

FOXBORO FBMSVL

Lifecycle Status and Migration Strategy

Schneider Electric has formally obsoleted the FBMSVL and the broader I/A Series FBM I/O architecture. Official support, including repair services and firmware updates, is no longer available. Continuing to operate systems with this module carries escalating risk: spare units are scarce, and undocumented refurbishments may compromise intrinsic safety certification.

Short-term mitigation options include:

- Sourcing tested-and-verified spares from certified industrial surplus vendors with full functional reports.

- Implementing segment-level redundancy (if not already in place) to tolerate single-module failure.

- Isolating critical loops onto separate fieldbus segments to limit blast radius.

For sustainable operation, migration to a modern DCS is necessary. Schneider Electric’s recommended path is transition to the EcoStruxure Foxboro DCS (formerly I/A Series G3). This involves:

- Replacing legacy FBM I/O carriers and modules with new Smart I/O (e.g., FBM248 for analog, FBM242 for discrete).

- Upgrading controllers to CP60 or CP80 platforms running updated system software.

- Retaining existing field wiring where possible by using compatible terminal blocks.

- Leveraging migration tools to convert control logic, though some re-engineering is typically required.

While migration requires capital investment, it restores access to vendor support, enhances cybersecurity, and enables integration with asset performance management (APM) and cloud analytics via OPC UA and MQTT. A staged approach—beginning with non-critical units—allows organizations to manage risk while modernizing infrastructure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: