Description

Key Technical Specifications (For Spare Verification)

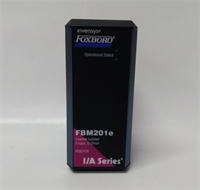

- Product Model: FBM222

- Terminal Unit: P0926TL

- Manufacturer: FOXBORO / Schneider Electric

- System Family: I/A Series DCS (Classic architecture, pre-System Platform)

- Input Channels: 16 differential analog inputs

- Supported Signal: 4–20 mA (sink configuration), with optional HART pass-through

- Input Impedance: ~250 Ω per channel

- Isolation: Channel-to-channel and field-to-system isolation via terminal unit

- Resolution: 16-bit A/D conversion

- Update Rate: Configurable, typically 100 ms to 2 seconds per channel

- Mounting: Plugs into FBM carrier backplane in I/O compartment

- Diagnostic Features: Module-level OK LED; open-circuit detection reported to controller

- Power: Supplied via backplane (±15 VDC, +5 VDC)

System Role and Downtime Impact

The FBM222, paired with the P0926TL terminal block, is a foundational analog input module in legacy FOXBORO I/A Series installations across oil & gas, power, and chemical plants. It digitizes critical process measurements—such as boiler drum level, compressor suction pressure, or reactor temperature—and delivers them to the controller for regulation and safety logic.

A failed FBM222 typically causes all 16 channels to go “bad quality” in the DCS, which may force affected control loops into manual mode or trigger high/low alarm cascades. In safety-instrumented functions (where used), this could initiate a partial or full plant trip. While some systems employ redundant I/O, most FBM222 deployments are single-channel, making spare availability essential for rapid recovery. Replacement requires system access during maintenance windows, and incorrect module revision can lead to communication faults or calibration errors.

Reliability Analysis and Common Failure Modes

The FBM222 is generally robust but exhibits predictable aging patterns. The most common failure modes include:

- Degraded analog front-end components (e.g., precision resistors, op-amps) leading to channel drift or offset errors

- Corrosion or loosening of the edge connector pins due to humidity or repeated insertion cycles

- Failed DC/DC converters on the board, causing partial or total loss of isolated power to input channels

- Damage to the P0926TL terminal unit from over-torqued screws or field wiring errors (e.g., voltage spikes)

A known vulnerability is sensitivity to ground loops if field wiring shielding is improperly grounded—a frequent cause of intermittent noise or channel saturation. Additionally, older revisions lack advanced diagnostics, making fault localization difficult without loop testing.

Recommended preventive actions include: periodic calibration verification using a precision current source, infrared inspection of terminal blocks for hot spots, and visual checks for PCB discoloration or capacitor leakage (though the module uses mostly solid-state components). Keeping the I/O cabinet clean and climate-controlled significantly extends service life.

FBM222 P0926TL FOXBORO

Lifecycle Status and Migration Strategy

Schneider Electric has formally obsoleted the classic I/A Series FBM222 as part of its transition to the modern Foxboro Evo and EcoStruxure™ Foxboro DCS platforms. No new units are manufactured, and official repair services are no longer offered. Continuing to operate on this hardware introduces significant risks: spares are increasingly scarce, prices are volatile, and counterfeit or misrepresented units are common in open markets.

As a short-term strategy, only functionally tested modules with verified compatibility (matching FBM and P0926TL revisions) should be deployed. Testing must include full-channel accuracy validation under load and communication handshake with the FBM carrier.

Schneider’s recommended long-term path is migration to Foxboro Evo, which uses the FTEB-based I/O architecture with modern equivalents such as the FCM222 (analog input module). This upgrade requires:

- Replacement of I/O carriers and terminal assemblies

- Retranslation of control logic (though much can be auto-converted)

- Recalibration of field loops

Alternatively, third-party solutions like PLC-based I/O gateways can bridge legacy 4–20 mA signals to newer control systems, though this adds integration complexity. Until a full migration is executed, maintaining at least one verified FBM222/P0926TL set per critical process area is essential for operational resilience.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: