Description

Key Technical Specifications (For Spare Part Verification)

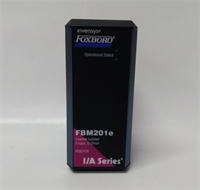

- Product Model: FBM216b

- Manufacturer: Foxboro (Schneider Electric)

- System Family: I/A Series DCS (Fieldbus Module platform)

- Input Channels: 8 differential thermocouple or millivolt inputs

- Supported Types: J, K, T, E, R, S, B, N, and user-defined mV ranges

- Cold Junction Compensation: Integrated per channel

- Isolation: 500 V DC channel-to-channel and channel-to-system

- Resolution: 16-bit A/D conversion

- Update Rate: ~200 ms per channel (configurable via FBM configuration block)

- Redundancy Support: Hot-swap capable in redundant FBM carrier configurations (e.g., with FBM201/204 baseplate)

- Revision Identifier: Lowercase “b” denotes a specific hardware/firmware iteration; not interchangeable with FBM216, FBM216a, or FBM216c without validation

- Power Consumption: ~3.5 W from FBM backplane

System Role and Downtime Impact

The FBM216b is a foundational analog input module in legacy Foxboro I/A Series installations, commonly deployed in refineries, petrochemical plants, and utilities for reactor temperature, boiler tube monitoring, and compressor bearing surveillance. It digitizes low-level thermocouple signals and transmits them via the proprietary Foxboro fieldbus to the CP (Control Processor) for logic execution and operator display.

In non-redundant configurations, failure of a single FBM216b results in complete loss of up to eight critical temperature points. In redundant systems, the backup module takes over—but only if properly configured and tested. Unnoticed degradation (e.g., cold junction drift) can cause silent measurement errors, leading to unsafe process conditions or false trips. Given its role in safety instrumented functions (SIFs), even partial failure may violate regulatory compliance (e.g., OSHA PSM, IEC 61511).

Reliability Analysis and Common Failure Modes

After 15–25 years of service, the FBM216b exhibits predictable aging patterns:

- Cold junction sensor drift: The onboard temperature reference for thermocouple compensation degrades over time, causing offset errors that mimic real process changes.

- Input channel burnout: Exposure to voltage transients (e.g., from nearby motor startups) can damage front-end amplifiers, resulting in fixed or erratic readings.

- Backplane connector fatigue: Repeated thermal cycling causes micro-cracks in solder joints at the edge connector, leading to intermittent communication or full dropout.

- Revision mismatch issues: Installing an FBM216 (no suffix) or FBM216c in place of an FBM216b may boot but exhibit timing or calibration differences that affect loop stability.

Recommended preventive actions:

- Perform annual calibration using a precision thermocouple simulator across multiple types (e.g., K and J).

- Monitor FBM diagnostic status in I/A Series Workbench for “channel fault” or “CJC error” flags.

- Verify redundancy switchover during scheduled outages.

- Store spares in climate-controlled, ESD-safe packaging with revision clearly labeled.

Foxboro FBM216b

Lifecycle Status and Migration Strategy

Schneider Electric has formally ended production of the FBM216 series. While basic technical documentation remains accessible, no new modules are available from the manufacturer, and repair services are discontinued. The secondary market is active but carries risks—many units are pulled from decommissioned sites without functional testing.

Interim risk controls:

- Procure only from vendors who provide full loop-test verification and revision confirmation.

- Maintain a minimum of one tested spare per unique application (e.g., reactor vs. flare stack).

- Implement enhanced process monitoring (e.g., inferential temperature estimation) as a temporary safeguard.

Long-term path: Schneider recommends migration to the Foxboro Evo DCS platform. Evo supports modern I/O (e.g., FTEB-based modules) with native OPC UA, but does not directly accept FBM216b. A staged approach—using gateway solutions or parallel skid control—can extend asset life while planning full replacement. Facilities operating beyond 2030 should initiate a lifecycle assessment immediately. Continued reliance on obsolete I/O like the FBM216b increases exposure to operational, safety, and compliance risk with each passing year.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: