Description

Key Technical Specifications (For Spare Part Verification)

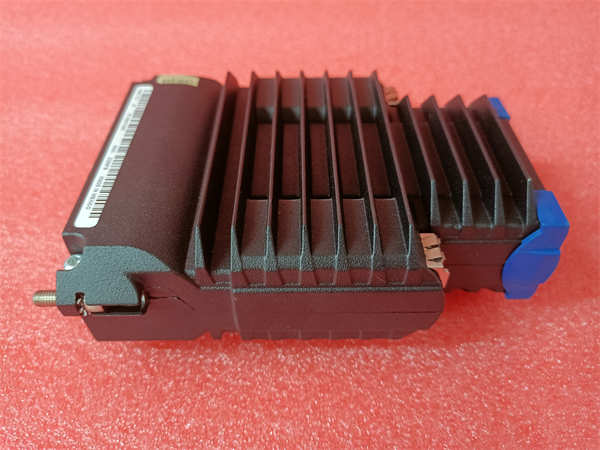

- Product Model: FCP270

- Manufacturer: Foxboro (Schneider Electric)

- System Compatibility: Foxboro I/A Series (Classic architecture, pre-DCS Evolution)

- Module Type: Fieldbus Communication Processor

- Part Number: P0917YZ (revision-specific identifier)

- Redundancy Support: Yes – supports 1:1 hot standby with a second FCP270 in the same node

- Fieldbus Capacity: Supports up to 8 Fieldbus Modules (FBMs) per FCP270

- Communication Interfaces: Dual redundant I/A Series process buses (proprietary coaxial or twisted-pair)

- Power Consumption: Approx. 5–7 W (from backplane)

- Mounting: DIN-rail mounted within I/A Series node cabinet, slot-specific (typically slots 1 and 2 for redundant pair)

- Diagnostic Indicators: LED status for power, active/standby, bus activity, and fault

System Role and Downtime Impact

The FCP270 serves as the critical bridge between the I/A Series operator stations/network and the field-level I/O (via FBMs such as FBM201, FBM207, etc.). It handles real-time polling, data buffering, and protocol translation for all connected I/O modules within its node. In a redundant configuration, one FCP270 operates as primary while the other remains in hot standby. If the active unit fails and redundancy is properly configured, switchover occurs automatically—but if both units fail, or if redundancy is not implemented, all I/O in that node becomes inaccessible. This can disable control loops, safety interlocks, and monitoring functions for an entire process skid or production area. In continuous-process industries like chemicals, oil refining, or power generation, such a failure may trigger emergency shutdowns with significant financial and safety implications.

Reliability Analysis and Common Failure Modes

The FCP270 is generally robust but exhibits predictable aging-related failures due to its early-2000s (or earlier) design era. The most common failure mode is capacitor degradation on the internal DC-DC converter or logic power rails, leading to intermittent resets, communication timeouts, or complete power-up failure. Backplane connector corrosion—especially in high-humidity environments—can cause poor contact, resulting in erratic bus errors or module dropout. Additionally, the custom ASICs or PROMs used for fieldbus protocol handling may suffer from bit rot or latch-up under electrical stress, particularly if the plant experiences frequent power sags or surges.

A key vulnerability is the reliance on battery-backed SRAM (in some revisions) for configuration retention. If the onboard battery depletes (typical lifespan: 5–10 years), the module may lose its node address or bus parameters, requiring reconfiguration via I/A Series engineering tools—a process that demands legacy software and expertise.

Recommended preventive actions include:

- Monitoring FCP270 diagnostic LEDs for “BUS FAULT” or “COMM ERROR” indications during routine rounds

- Verifying redundant pair synchronization status in the I/A Series system health display

- Replacing units proactively if installed over 15 years ago, even if currently functional

- Ensuring clean, stable 24 VDC power to the node cabinet to minimize stress on internal regulators

FCP270 P0917YZ FOXBORO

Lifecycle Status and Migration Strategy

Schneider Electric has formally obsoleted the FCP270 as part of the I/A Series Classic platform end-of-life roadmap. Official support is limited to break-fix scenarios, and no factory-new units are available. Continuing to operate systems with FCP270 modules carries escalating risks: diminishing spare availability, loss of in-house expertise, and increasing mean time to repair (MTTR).

Short-term risk mitigation includes:

- Securing multiple tested, matched-pair spares with verified redundancy handover capability

- Performing functional validation of each spare in a test rack before storage

- Documenting node configurations and bus termination settings for rapid recovery

For long-term sustainability, Schneider Electric’s recommended path is migration to the I/A Series DCS Evolution platform (e.g., using AC 900F or Symphony Plus controllers). This involves:

- Replacing FCP270/FBM racks with modern I/O subsystems (e.g., CI854-based)

- Retaining existing field wiring via terminal block adapters where possible

- Reusing or converting control logic through automated translation tools (with manual validation)

- Upgrading operator stations to modern Windows/Linux-based consoles

Such a migration typically requires 6–18 months of planning but eliminates single-point-of-failure risks associated with aging FCP270 hardware. Engineering assessment is essential to scope the effort based on system size and regulatory requirements.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: