Description

Key Technical Specifications (For Spare Parts Verification)

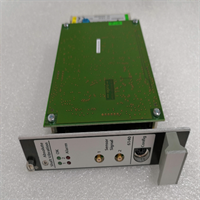

- Product Model: SE3008 KJ2005X1-SQ1

- Manufacturer: Emerson (formerly Fisher-Rosemount)

- System Family: DeltaV DCS (version 5.x–7.x era)

- Module Type: Serial Interface Card (part of the DeltaV Serial Interface family)

- Physical Form: Half-height I/O card for DeltaV M-series or S-series I/O chassis

- Communication Ports: Dual isolated RS-485 channels (DB9 connectors on terminal block adapter)

- Supported Protocols: Modbus RTU, Modbus ASCII, DF1, and custom ASCII-based protocols

- Baud Rate Range: 300 to 115.2 kbps (configurable per channel)

- Power Consumption: ~2.5 W (supplied via DeltaV backplane)

- Diagnostic Features: Per-channel TX/RX activity LEDs, fault relay output

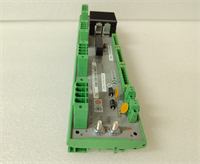

- Required Adapter: KJ2221X1-ET1 terminal block assembly (must be verified for compatibility)

System Role and Downtime Impact

The SE3008 KJ2005X1-SQ1 serves as a critical integration bridge in mid-life DeltaV systems, commonly found in oil & gas, chemical, and pharmaceutical plants commissioned between 2000 and 2010. It enables the DeltaV controller to communicate with third-party devices that lack native Foundation Fieldbus or HART support—such as gas chromatographs, legacy motor control centers, or proprietary analyzers. The module is typically installed in remote I/O cabinets near process units.

If this module fails, all serially connected devices lose communication with the DCS. While not always triggering an immediate safety shutdown, it results in loss of critical process variables (e.g., composition, pH, or flow correction factors), forcing operators into manual mode or causing regulatory compliance issues. In batch processes, missing analyzer data can invalidate entire production lots. Because these modules are often deployed without redundancy, a single point of failure can degrade operational integrity across multiple unit operations.

Reliability Analysis and Common Failure Modes

Although designed for industrial environments, the SE3008 is susceptible to long-term degradation due to its reliance on aging semiconductor components and external cabling exposure. The most common failure mode is RS-485 transceiver IC failure, often caused by ground potential differences or lightning-induced surges on field wiring—despite isolation, repeated transient events fatigue the protection circuitry. Internal electrolytic capacitors on the DC/DC converter board also degrade over time, leading to intermittent resets or complete power dropout.

A key design vulnerability is the lack of hot-swap capability and limited self-diagnostics: the module provides only basic LED indicators, making fault isolation difficult without a laptop running DeltaV Diagnostics. Additionally, configuration is stored in battery-backed SRAM; if the onboard coin-cell battery depletes (typical lifespan 7–10 years), the protocol settings are lost on power cycle, requiring re-download from the workstation.

Preventive maintenance should include: inspecting field cable shielding and grounding at both ends, verifying terminal block torque annually, monitoring serial error counters in DeltaV Diagnostics, and replacing the internal backup battery proactively every 8 years. Keeping a validated spare—pre-loaded with the correct configuration—is essential for rapid recovery.

SE3008 KJ2005X1-SQ1 12P6383X032 EMERSON

Lifecycle Status and Migration Strategy

Emerson has formally obsoleted the SE3008 series, with no direct replacement offered in current DeltaV releases. Official support ended years ago, and firmware updates are no longer issued. Continued use poses escalating risk: spare units are scarce, counterfeit modules have entered the gray market, and newer DeltaV versions (v14+) may lack full driver compatibility.

As an interim solution, facilities can source and functionally test surplus modules from reputable vendors who verify protocol operation under load. Some users implement external protocol converters (e.g., Modbus TCP-to-RTU gateways) to offload serial traffic, though this adds complexity and latency.

The strategic path is migration to modern communication standards. Emerson recommends replacing serial-dependent devices with native Fieldbus, HART, or Ethernet/IP instruments where possible. For unavoidable serial devices, the DeltaV Smart Switch (or third-party OPC UA servers) can act as a centralized protocol gateway, consolidating legacy interfaces outside the core I/O chassis. This approach reduces reliance on obsolete hardware, improves cybersecurity posture, and simplifies future upgrades. A full assessment of connected devices should precede any migration plan to prioritize high-impact replacements.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: