Description

Technical Specifications (For Spare Part Verification)

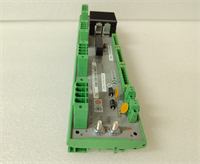

- Model: MV6100COMI

- Manufacturer: Emerson Process Management (now part of Emerson Automation Solutions)

- System Family: DeltaV Distributed Control System (DCS), M-Series I/O Platform

- Module Type: M-Bus Communication Interface for I/O Carriers

- Physical Form: DIN-rail mounted carrier module with integrated COM interface

- Compatible I/O Cards: MV6110, MV6120, MV6130, MV6140 series analog and discrete I/O modules

- Communication Protocol: Proprietary DeltaV M-bus (serial backplane)

- Power Supply: +5 V DC from I/O carrier backplane

- Diagnostic Indicators: LED status for power, communication activity, and fault

- Firmware Dependency: Requires matching firmware version with DeltaV controller and I/O cards

System Role and Downtime Impact

The MV6100COMI is not a standalone field device—it is the embedded communication engine within Emerson’s M-series I/O carriers. Each I/O carrier (e.g., 8-slot chassis) relies on one MV6100COMI to relay all input/output data between local I/O cards and the central DeltaV controller over the redundant M-bus network. If this module fails, the entire I/O carrier becomes unresponsive, causing loss of signal for up to 32 I/O points (depending on configuration). In a refinery or chemical plant, this could mean loss of critical pressure, temperature, or valve position feedback—potentially triggering safety interlocks, process shutdowns, or manual intervention. Because these carriers are often deployed in safety-instrumented or regulatory-compliant loops, unplanned failure carries operational, safety, and compliance consequences.

Reliability Analysis and Common Failure Modes

Despite its solid-state design, the MV6100COMI is vulnerable to age-related degradation common in early-2000s industrial electronics. The most frequent failure mode is communication dropout due to degraded surface-mount capacitors on the power regulation circuit, leading to intermittent resets or complete loss of M-bus synchronization. Another known weakness is sensitivity to electrical transients on the backplane—especially in systems where grounding or surge protection was not rigorously maintained during installation. Unlike newer modules, the MV6100COMI lacks advanced self-diagnostics; a “COMM FAULT” LED may illuminate, but root cause analysis often requires swapping the module or using legacy DeltaV diagnostic tools.

As a maintenance best practice, sites still operating M-series I/O should:

- Perform annual thermal imaging of I/O cabinets to detect abnormal heating on carrier modules

- Verify stable +5 V backplane voltage at the carrier connector (fluctuations >±5% accelerate component wear)

- Maintain spare carriers with pre-tested MV6100COMI modules in climate-controlled storage

- Avoid hot-swapping unless explicitly permitted by the original system documentation, as electrostatic discharge can damage the COM ASIC

Emerson MV6100COMI

Lifecycle Status and Migration Strategy

Emerson officially discontinued the MV6100COMI and the entire M-series I/O platform years ago, with last-time buy opportunities exhausted. Continued use presents significant risks: no factory warranty, no firmware updates, and increasing difficulty in verifying authenticity of secondary-market units. Counterfeit or refurbished modules without proper burn-in testing may fail prematurely, creating false economy.

In the short term, asset owners can mitigate risk by:

- Securing tested, traceable spares from reputable automation lifecycle specialists

- Implementing board-level repair programs with vendors who have original schematics and test fixtures

- Isolating M-series I/O to non-critical loops where possible

For long-term sustainability, Emerson’s recommended migration path is to transition to the DeltaV S-series I/O platform (e.g., SD6100/SD6200 carriers with SD COM modules). This upgrade preserves the DeltaV control strategy and HMI graphics but requires:

- Replacement of I/O carriers and terminal blocks

- Reconfiguration of I/O assignments in DeltaV Studio

- Recalibration of field instruments due to updated channel characteristics

While the migration involves upfront engineering effort, it eliminates obsolescence risk, improves diagnostics, and aligns the system with modern cybersecurity standards—making it a strategic investment for facilities planning 5+ years of continued operation.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: