Description

Key Technical Specifications (For Spare Parts Verification)

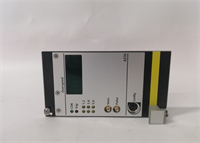

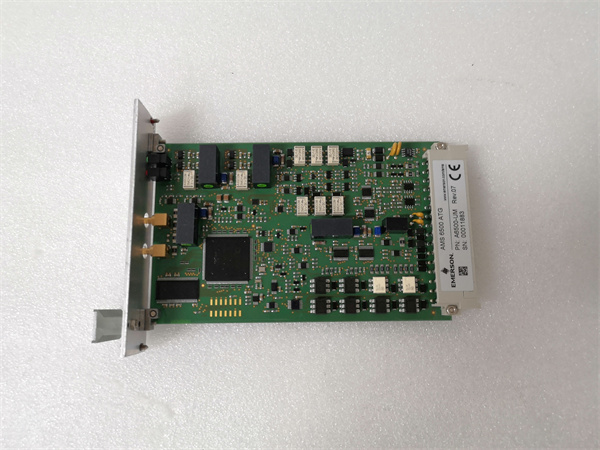

- Product Model: A6500-UM

- Manufacturer: Emerson Automation Solutions

- System Platform: DeltaV S-series (Serial Number prefix typically “S-”)

- Module Type: Universal I/O (configurable per channel via software)

- Channel Count: 8 independent channels

- Supported Signal Types:

- Analog Input: 4–20 mA, 0–10 V DC

- Analog Output: 4–20 mA

- Digital Input: 24 V DC sourcing/sinking

- Digital Output: 24 V DC, relay or solid-state (depending on terminal block)

- Isolation: 500 V AC between field and system ground

- Communication: Proprietary serial backplane to S-series controller (e.g., S1, S2)

- Configuration: Set via DeltaV Explorer during commissioning; stored in module EEPROM

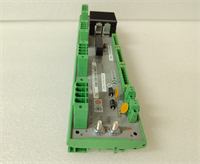

- Terminal Block: Requires specific A65xx-compatible removable terminal blocks (e.g., A6510-TB)

- Diagnostic Features: Per-channel status LEDs, open-wire detection, overrange indication

- Power: Supplied via I/O carrier backplane

System Role and Impact of Failure

The Emerson A6500-UM was a cornerstone of the DeltaV S-series architecture, deployed extensively in mid-sized process facilities from the late 1990s through the 2000s. Its key innovation was “universal” channel assignment—each of the eight channels could be independently configured as AI, AO, DI, or DO via software, reducing spare parts inventory and increasing design flexibility.

In service, this module typically interfaces with critical field devices such as control valve positioners, pressure transmitters, motor starters, and safety switches. A failure can disrupt multiple control loops or interlocks simultaneously. Because the S-series lacks full redundancy in many installations, loss of an A6500-UM often forces manual operation or partial plant derating. In batch or continuous processes—such as pharmaceutical manufacturing or chemical blending—even brief signal loss can compromise product quality or trigger safety system interventions.

Reliability Analysis and Common Failure Modes

Despite its robust design, the A6500-UM is now operating well beyond its intended lifecycle. The most common failure mechanisms include:

- EEPROM corruption: The module stores its configuration in non-volatile memory that degrades over time, especially with frequent power cycles. This can cause channels to revert to default states or become unresponsive.

- Analog front-end drift: Precision resistors and op-amps in the 4–20 mA input path age, leading to calibration shifts outside acceptable tolerances.

- Digital output driver failure: Solid-state switching components fatigue under inductive loads (e.g., solenoids), resulting in stuck-on or stuck-off states.

- Backplane connector wear: Repeated insertion/removal or thermal cycling causes fretting corrosion on the edge connector, leading to intermittent communication with the controller.

A key vulnerability is its dependency on stable field wiring practices. Ground loops or voltage transients—common in older plants—can damage input protection circuits without triggering visible faults.

Recommended preventive actions for maintenance teams:

- Perform annual loop calibration checks using a certified mA source

- Verify module configuration matches DeltaV database after any power event

- Inspect terminal blocks for discoloration or loose screws

- Monitor DeltaV diagnostic logs for “I/O module offline” or “channel fault” events

EMERSON A6500-UM

Lifecycle Status and Migration Strategy

Emerson officially discontinued the A6500-UM as part of the DeltaV S-series end-of-life announcement. No new modules are manufactured, and Emerson no longer provides repair, calibration, or technical support for S-series hardware. Continuing to operate with this module carries significant risk: unverifiable performance, no warranty, and escalating costs for scarce spares.

Short-term mitigation includes:

- Securing tested, functionally verified spares from reputable industrial surplus suppliers

- Implementing loop redundancy where process criticality justifies it

- Avoiding unnecessary module reseating to preserve backplane integrity

For long-term sustainability, Emerson’s recommended migration path is upgrading to the DeltaV M-series or DeltaV PK Controller platforms. While there is no direct drop-in replacement, the M-Series AM-2320 (8-channel universal I/O) offers equivalent functionality with modern diagnostics, cybersecurity compliance, and full vendor support. Migration requires:

- Replacement of I/O carriers and terminal blocks

- Rewiring of field connections (though often using existing cable trays)

- Reconfiguration of I/O assignments in DeltaV Studio

- Possible logic review due to timing differences

Given the age of most S-series installations, a phased migration—starting with the most critical or failure-prone I/O racks—is the most pragmatic approach to ensure operational continuity while restoring access to engineering support and future enhancements.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: