Description

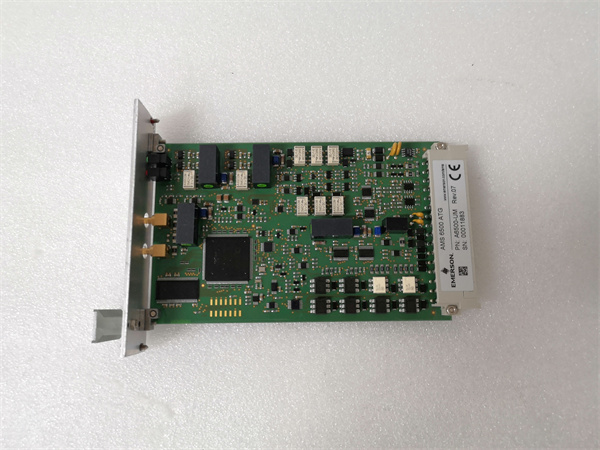

Technical Specifications (For Spare Parts Verification)

- Model: A6500-CC

- Emerson P/N: 9199-00120

- System Family: DeltaV SIS (based on original Triconex TMR architecture, rebranded under Emerson)

- Architecture: Triple-Modular Redundant (TMR) – three independent microprocessor channels with voting

- Safety Integrity Level: Certified to IEC 61508 SIL 3 and IEC 61511

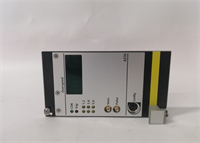

- Mounting: Designed for A6500 chassis (typically in 19″ rack with redundant power and I/O modules)

- Communication: Proprietary Triconex network (TriBus) for internal module sync; supports Modbus TCP/IP or OPC for DeltaV integration

- Diagnostic Coverage: >99% via continuous self-testing of processors, memory, and I/O paths

- Power Input: +24 VDC via redundant A6500 power supplies (e.g., A6590-PS)

- Operating Temperature: 0°C to 60°C (industrial grade)

- Firmware: Requires Triconex Toolsuite or DeltaV SIS configuration software for logic download and diagnostics

- Physical ID: Label includes “A6500-CC”, “9199-00120”, and serial number; red status LEDs indicate fault or sync status

System Role and Downtime Impact

The Emerson A6500-CC is the brain of a DeltaV SIS safety system, commonly deployed in high-hazard industries such as oil & gas, petrochemicals, and power generation. It continuously monitors critical process variables (e.g., pressure, temperature, level) and triggers predefined safety actions—like closing emergency isolation valves or tripping compressors—when thresholds are exceeded.

Because it operates independently of the basic process control system (BPCS), its reliability is paramount. A failure in the A6500-CC (e.g., due to internal channel fault or loss of synchronization) can cause:

- Spurious trip: Unplanned plant shutdown, costing hundreds of thousands per hour in lost production.

- Dangerous failure: Inability to respond to a real hazard, risking fire, explosion, or environmental release.

In non-redundant configurations (rare but possible in older installations), a single A6500-CC failure disables the entire SIF. Even in TMR systems, repeated faults may force the system into a “restricted” mode, requiring manual intervention and regulatory reporting.

Reliability Analysis and Common Failure Modes

Despite its robust TMR design, the A6500-CC is not immune to aging effects, especially in units installed before 2010.

Common failure modes include:

- Capacitor degradation on internal DC/DC converters, leading to voltage instability and channel resets.

- Memory bit errors in SRAM or flash due to cosmic rays or aging—though TMR voting usually masks single-bit faults.

- Connector corrosion on the backplane interface, causing intermittent communication with I/O modules.

- Firmware corruption after uncontrolled power cycles, particularly if backup batteries are depleted.

Design strengths include hardware-based voting and continuous diagnostics, but weaknesses include dependence on aging discrete components and limited remote troubleshooting capability without proprietary tools.

Preventive maintenance recommendations:

- Monitor SIS health logs in DeltaV for “channel mismatch” or “voter fault” warnings.

- Replace backup batteries every 5 years (even if not alarming).

- Perform annual partial stroke testing of final elements to verify end-to-end SIF integrity.

- Keep spare A6500-CC modules in climate-controlled, ESD-safe storage with firmware pre-loaded.

EMERSON A6500-CC 9199-00120

Lifecycle Status and Migration Strategy

Emerson has formally obsoleted the A6500 series, including the A6500-CC (9199-00120), and transitioned support to the DeltaV SIS Gen II platform based on updated Triconex mp (microprocessor) architecture (e.g., M5310 or M5320 controllers).

While Emerson may still offer limited repair services for existing A6500 systems under extended support contracts, no new A6500-CC units are manufactured, and firmware updates have ceased.

Short-Term Mitigation:

- Source certified refurbished A6500-CC modules from Emerson-authorized partners with full functional test reports.

- Implement cold spares with verified firmware compatibility.

- Ensure all SIF logic is fully documented for future migration.

Long-Term Migration Path:

Emerson’s recommended upgrade is to DeltaV SIS Gen II using Triconex mp-series controllers:

- Replace A6500 chassis with M5300 or M5400 carrier frames.

- Swap A6500-CC with M5310 (non-redundant) or M5320 (redundant) controllers.

- Retain existing field wiring and I/O modules where compatible (many A6500 I/O modules work with mp chassis via adapter kits).

- Reuse safety logic with minimal changes using Triconex Enhanced Diagnostic Manager (EDM) or DeltaV SIS Studio.

This migration restores access to cybersecurity patches, regulatory compliance support (e.g., IEC 62443), and integration with modern asset management systems. Although it requires engineering effort and recertification of SIFs, it eliminates obsolescence risk and ensures long-term operational safety.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: