Description

Key Technical Specifications (For Spare Part Verification)

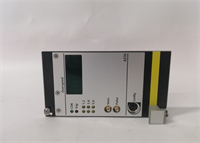

- Product Model: 5X00790G01

- Manufacturer: EMERSON

- System Family: Ovation™ Distributed Control System (DCS)

- Module Type: Digital Input (DI) Module, 16 channels, isolated

- Input Voltage Range: 24 V DC nominal (typically 18–30 V DC acceptable)

- Input Type: Sink or source configurable (depending on terminal block wiring)

- Isolation: Channel-to-channel and channel-to-backplane isolation (typically >500 V RMS)

- Backplane Interface: Connects to Ovation I/O carrier card (e.g., 5X00144Gxx series) via DIN rail-mounted base

- Diagnostic Features: Per-channel LED indicators for signal status; module-level fault indication

- Mounting: DIN rail mount within Ovation I/O cabinet

- Form Factor: Standard Ovation I/O module width (~35 mm)

- Compatibility: Requires specific firmware version in Ovation controller; G01 revision may not be replaceable with G02+ without configuration updates

System Role and Downtime Impact

The 5X00790G01 is a foundational I/O component in Ovation-based power plants, refineries, and industrial facilities. It digitizes critical binary field signals—such as turbine trip flags, pump running status, or fire detection contacts—and delivers them to the Ovation controller for logic execution. A failure of this module results in loss of visibility for up to 16 process points, which can disable interlocks, cause false alarms, or prevent automatic sequences from executing. In safety-critical applications (e.g., boiler protection or emergency shutdown systems), such a failure may force operators into manual mode or trigger a controlled plant derate. Because Ovation systems often lack per-module redundancy at the I/O level, this board represents a single point of failure for its assigned signals.

Reliability Analysis and Common Failure Modes

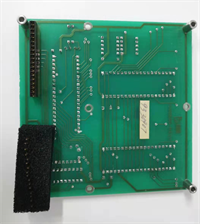

Despite robust industrial design, the 5X00790G01 is susceptible to long-term degradation due to electrical stress and environmental exposure. The most common failure mode is optocoupler degradation in the input isolation circuitry, leading to signal dropout or intermittent contact—especially on channels frequently switched or exposed to voltage transients. Electrolytic capacitors on the internal DC/DC converter stage (used for isolation power) dry out after 10–15 years, causing unstable logic levels or complete module reset. Additionally, corrosion on terminal block screws or PCB traces—accelerated by high humidity or sulfur-rich atmospheres—can increase contact resistance and cause false “open” readings. Recommended preventive actions include annual verification of input signal integrity using a calibrated simulator, thermal imaging of terminal blocks for hot spots, ensuring cabinet humidity remains below 60% RH, and applying conformal coating during refurbishment if operating in harsh environments.

EMERSON 5X00790G01

Lifecycle Status and Migration Strategy

Emerson has discontinued the 5X00790G01 as part of its product lifecycle management for early Ovation I/O modules. No new units are available through official channels, and Emerson no longer provides repair services or replacement documentation for the G01 revision. Continued operation relies on surplus inventory or third-party rebuilders, often without performance validation. As a short-term measure, sites may implement strategic sparing with periodic functional testing or consolidate low-priority signals onto newer, supported DI modules where possible. However, the sustainable path is migration to current-generation Ovation I/O hardware, such as the 5X00790G02 or G03 variants, which offer enhanced diagnostics, better noise immunity, and extended lifecycle support. This upgrade typically requires updating the I/O configuration in Ovation Engineering Studio and may involve terminal block rewiring. For greenfield or major modernization projects, Emerson recommends transitioning to the Ovation Expert platform with Ethernet-based I/O (e.g., DeltaV I/O on CHARON), enabling tighter integration with asset management and predictive maintenance tools while reducing long-term obsolescence risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: