Description

Technical Specifications (For Spare Parts Verification)

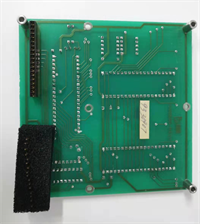

- Product Model: 5X00273G01

- Manufacturer: EMERSON Automation Solutions (Ovation DCS)

- System Family: Ovation v2 / v3 Distributed Control System

- Module Type: Analog Output (AO)

- Number of Channels: 8

- Output Signal Range: 4–20 mA (sink/source capable, depending on terminal block)

- Load Drive Capability: Up to 750 Ω per channel

- Isolation: Channel-to-backplane isolation (500 V DC typical)

- Update Rate: ~100 ms per channel (system-dependent)

- Terminal Block Compatibility: Requires Ovation-specific removable terminal blocks (e.g., 5X00166G01)

- Diagnostic Features: Basic open-circuit detection (via Ovation controller logic)

- Physical Form: Standard Ovation I/O carrier card (plugs into I/O chassis with redundant power/backplane)

System Role and Downtime Impact

The 5X00273G01 serves as the final output stage in critical control loops within Ovation-based power and water systems. It translates digital setpoints from the controller into precise 4–20 mA signals that drive actuators—such as feedwater control valves, damper positioners, or chemical dosing pumps. In a coal-fired boiler, for example, a failed AO module could disable multiple combustion air controls, triggering a master fuel trip (MFT) or forcing manual operation under strict regulatory limits. Because these modules are often deployed without per-channel redundancy, a single point failure can degrade or disable an entire functional group. Recovery requires physical replacement and re-commissioning, which in regulated environments may necessitate outage windows and compliance documentation.

Reliability Analysis and Common Failure Modes

Although designed for industrial environments, the 5X00273G01 is increasingly prone to age-related degradation due to its use of early surface-mount electronics and analog components:

- Output driver IC failure: The current-output amplifiers (typically precision op-amp + transistor circuits) drift or fail shorted/open after prolonged thermal stress, causing fixed or erratic outputs.

- Electrolytic capacitor aging: Onboard filtering capacitors lose capacitance over time, leading to increased output ripple or instability under load.

- Terminal block corrosion: Moisture ingress in non-climate-controlled I/O cabinets causes oxidation on spring-clamp terminals, increasing contact resistance and inducing signal errors.

- Backplane connector wear: Repeated insertion/removal or vibration loosens the edge connector pins, resulting in intermittent communication or power loss.

- Lack of advanced diagnostics: Unlike newer Ovation AO modules, this unit provides no per-channel health feedback—failures are only detected when field devices behave abnormally.

Recommended preventive actions:

- Perform annual loop calibration checks using a precision mA source/sink

- Inspect terminal blocks for discoloration or loose wires during scheduled outages

- Monitor output trends in Ovation Workstation for signs of drift or saturation

- Maintain spares in temperature/humidity-controlled storage to slow component aging

EMERSON 5X00273G01

Lifecycle Status and Migration Strategy

Emerson discontinued the 5X00273G01 in the mid-to-late 2000s, replacing it with higher-density, better-diagnosed modules like the 5X00473G01 (16-channel AO with HART support). Official repair services and firmware updates are no longer available. Continued operation carries escalating risks: diminishing spares availability, inability to validate performance post-failure, and growing incompatibility with cybersecurity mandates for critical infrastructure.

Interim Mitigation Measures:

- Source tested, burned-in units from certified Ovation surplus vendors

- Implement loop-level redundancy at the field device level (e.g., dual valves) where feasible

- Use external signal conditioners or isolators to protect the module from field-side transients

Recommended Migration Path:

Emerson’s strategic upgrade path involves migrating to the Ovation v4/v5 I/O architecture, which includes:

- Replacement of legacy I/O carriers with 5X004xx-series modules

- Retention of existing field wiring via compatible terminal blocks (in many cases)

- Enhanced diagnostics, higher channel density, and optional HART communication

This migration typically does not require full controller replacement but does necessitate:

- Updating I/O configuration in Ovation Engineering Studio

- Recalibrating all affected loops

- Validating control logic response times

For facilities planning long-term DCS life extension, early engagement with Emerson-certified system integrators is advised to develop a phased I/O modernization plan—reducing reliance on obsolete modules like the 5X00273G01 before an unplanned failure forces emergency procurement at premium cost.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: