Description

Key Technical Specifications (For Spare Parts Verification)

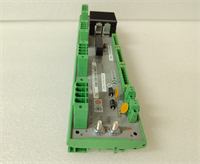

- Manufacturer Part Number: 5X00226G02

- Manufacturer: Emerson Automation Solutions

- System Family: Ovation Expert Control System

- Module Type: Analog Output (AO), 8 channels

- Output Signal: 4–20 mA, sink/source capable (typically loop-powered by field device)

- Load Drive Capability: Up to 750 Ω per channel (at 24 V DC)

- Accuracy: Typically ±0.1% of span (when new)

- Update Rate: ~100 ms per channel (system-dependent)

- Isolation: Channel-to-channel and field-to-system isolation via opto-couplers or isolation amplifiers

- Diagnostic Features: Per-channel open-circuit detection, overrange/underrange flags, module status LEDs, fault reporting to Ovation Workstation

- Mounting: Plug-in module in standard Ovation I/O carrier/backplane (e.g., in local or remote I/O chassis)

- Compatibility: Requires compatible Ovation I/O baseplate and firmware; used in Ovation systems from late 1990s through early 2010s

System Role and Downtime Impact

The Emerson 5X00226G02 is a critical interface between the Ovation controller logic and field-level final control elements. It commonly drives signals to control valve positioners, variable frequency drives (VFDs), damper actuators, and chemical dosing pumps in applications such as boiler feedwater control, combustion air modulation, or effluent pH adjustment. Failure or drift in this module can result in incorrect actuator positioning, leading to process instability (e.g., drum level swings), safety limit excursions (e.g., high furnace pressure), or environmental compliance violations (e.g., excess emissions). In non-redundant configurations—which are typical for auxiliary loops—a single module failure can disable up to eight control loops simultaneously, potentially forcing derating or shutdown of affected equipment. Replacement requires physical installation, loop calibration, and validation against control strategy setpoints, all of which are significantly delayed by spare parts scarcity and the need for skilled commissioning resources.

Reliability Analysis and Common Failure Modes

Despite robust original design, the 5X00226G02 is now subject to age-related degradation due to its likely 15–25 year service life. The most common failure modes include:

- DAC (Digital-to-Analog Converter) drift or failure, causing output offset/gain errors that manifest as persistent control bias (e.g., valve always 5% open when commanded closed).

- Degradation of output driver transistors or op-amps, leading to reduced current drive capability—especially under high loop resistance—resulting in “dropped” signals at the field device.

- Drying out of internal filtering capacitors, increasing output noise or ripple, which can cause actuator hunting or false diagnostics.

- Corrosion or oxidation on backplane connectors, creating intermittent contact and erratic output behavior that is difficult to reproduce during testing.

A key vulnerability is the lack of hot-swap capability; replacement typically requires de-energizing the I/O chassis or accepting temporary loss of control. Preventive measures include periodic loop calibration checks, monitoring output vs. feedback trends in historical data, inspecting for burnt components or bulging capacitors, and ensuring clean, dry operating environments.

EMERSON 5X00226G02

Lifecycle Status and Migration Strategy

Emerson has formally discontinued the 5X00226G02 as part of its transition to modern Ovation I/O architectures (e.g., Ovation 3.x with enhanced cybersecurity and higher channel density). No new units are available through official channels. Continued reliance on this module poses significant operational and compliance risks:

- Surplus modules may have unknown usage history, latent faults, or counterfeit components.

- Lack of factory support limits troubleshooting depth and firmware compatibility assurance.

- Regulatory audits (e.g., NERC CIP, EPA) increasingly scrutinize use of unsupported legacy hardware.

Short-Term Mitigation:

- Source only from certified vendors with full functional test reports (including load testing at 750 Ω and diagnostic verification).

- Implement pre-installation burn-in and calibration procedures.

- Maintain a small inventory of verified spares for mission-critical loops.

Long-Term Strategy:

Migrate to current-generation Ovation analog output modules, such as:

- 5X00226G03 (if pin/software compatible), or

- Newer high-density AO packs in the Ovation Smart I/O family (e.g., 5X00888-series), which offer:

- Enhanced diagnostics (HART pass-through, real-time health monitoring)

- Improved accuracy and noise immunity

- Support for modern engineering tools (Ovation Developer Studio)

- Cybersecurity features compliant with IEC 62443

While migration requires upfront investment in hardware, re-commissioning, and possible control logic updates, it eliminates obsolescence risk, improves process reliability, and ensures long-term access to vendor support—critical for operators managing essential infrastructure assets well into the 2030s and beyond.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: