Description

Technical Specifications (For Spare Parts Verification)

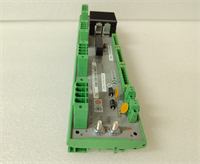

- Product Model: 1000554

- Manufacturer: Emerson (Fisher-Rosemount)

- Associated System: DeltaV Distributed Control System – M3/M5 Controller Platform (pre-v12 era)

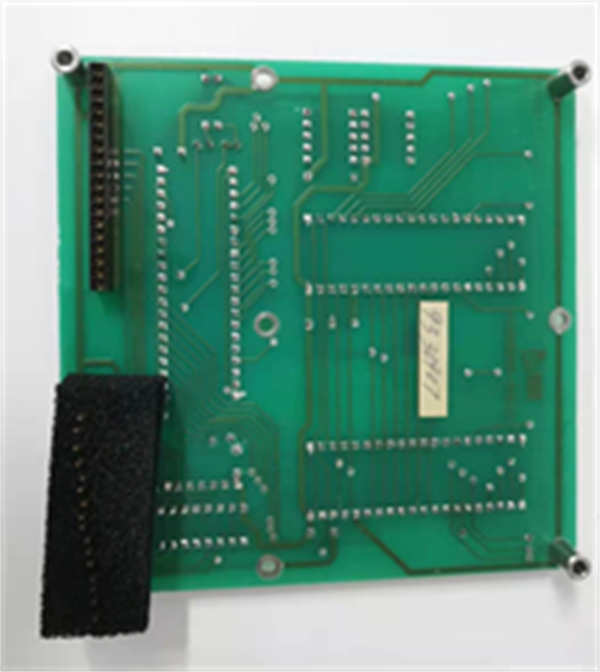

- Component Type: Masked PROM or OTP EPROM (One-Time Programmable)

- Memory Capacity: Typically 512 KB – 1 MB (exact size varies by DeltaV version)

- Package Type: 32-pin DIP or PLCC surface-mount IC

- Function: Stores low-level boot firmware, FPGA initialization sequence, and hardware ID

- Programming Method: Factory-programmed; not field-upgradable

- Compatibility: Tied to specific DeltaV controller board revision (e.g., 10005-xx series)

- Failure Symptom: Controller fails POST (Power-On Self-Test), displays “Firmware Error” or blank status LEDs

System Role and Downtime Impact

The 1000554 PROM resides on the main CPU board of early DeltaV M-series controllers and is responsible for the initial hardware bring-up sequence before the main operating system loads from flash memory. Without a valid, matching PROM image, the controller cannot initialize its communication interfaces, I/O backplane, or real-time kernel—rendering the entire control module inoperative. In a redundant DeltaV pair, failure of this chip in both primary and secondary units (e.g., due to latent manufacturing defect or ESD event) would result in a complete loss of control for that I/O domain. In continuous-process industries like refining or pharmaceuticals, this could trigger a full unit trip, leading to production losses exceeding $ 1M per day, in addition to safety and environmental reporting obligations.

Reliability Analysis and Common Failure Modes

Although solid-state, the 1000554 is susceptible to several failure mechanisms. The most common is data degradation due to charge leakage in older EPROM technology, especially in high-temperature control rooms (>40°C ambient), which can corrupt critical boot vectors over 15–20 years. A second risk is electrostatic discharge (ESD) during maintenance, which can silently damage the memory array without visible signs. Additionally, thermal stress from repeated power cycling can cause micro-cracks in solder joints beneath the PLCC package, leading to intermittent boot failures.

A key vulnerability is the lack of redundancy or error correction—these early PROMs contain no checksum validation at boot, so partial corruption may allow the controller to start but operate unpredictably. Furthermore, because the chip is soldered directly to the board, replacement requires skilled rework and access to an exact binary image, which Emerson no longer distributes.

Recommended preventive actions include:

- Maintaining strict ESD protocols during any controller handling

- Monitoring control room temperature and ensuring adequate ventilation around DeltaV cabinets

- Keeping verified spare controller boards (with known-good PROMs) in climate-controlled storage

- Documenting the exact firmware and hardware revision of all M-series controllers for future recovery

EMERSON 1000554

Lifecycle Status and Migration Strategy

Emerson discontinued the use of discrete PROMs like 1000554 with the introduction of the DeltaV v12 platform, which migrated to integrated flash memory with field-upgradable firmware. Official support for M3/M5 controllers ended years ago, and Emerson no longer provides board-level repairs or firmware images for these legacy systems.

For sites still operating this hardware, two practical approaches exist:

- Board-level sparing: Acquire multiple original M3/M5 controller boards in known-working condition as cold spares.

- Professional reprogramming: Partner with specialized industrial electronics labs capable of reading, verifying, and reprogramming compatible EPROMs using archived firmware (if legally obtainable).

The strategic path forward is migration to DeltaV S-series or M5x controllers, which offer modern cybersecurity features, virtualization support, and seamless integration with Plantweb™ digital ecosystem tools. While this requires re-commissioning of control logic and I/O verification, it eliminates dependency on unobtainable subcomponents like 1000554. Given the criticality of control system availability, proactive planning for this obsolescence is essential to avoid catastrophic, unrecoverable failures.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: