Description

Technical Specifications (For Spare Parts Verification)

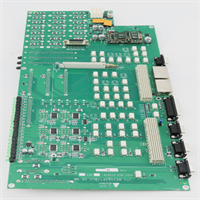

- Product Model: EPCPCRA#136 B5

- Manufacturer: Unknown / Proprietary (common in OEM-built skids, packaging machines, or test systems)

- Revision: B5 (indicating at least five design iterations—suggests long field use and possible reliability tuning)

- Form Factor: Industrial PCB, likely DIN-rail mountable or panel-mounted within an enclosure

- Key Markings: Silkscreen label “EPCPCRA#136 B5”; may include unmarked ICs, FPGA/CPLD, or microcontroller

- Power Input: Estimated 24 VDC (standard for industrial embedded boards), possibly with onboard regulation to 5 V/3.3 V

- Interfaces (Inferred):

- Digital I/O (TTL or 24 V)

- Serial ports (RS-232/485)

- Possible CANopen, Profibus, or Modbus RTU for field communication

- May feature Ethernet PHY for TCP/IP if used as a gateway

- Programmable Elements: Likely contains flash memory or FPGA requiring firmware image for full restoration

- Operating Environment: Designed for 0°C to +60°C, non-condensing, typical of factory automation enclosures

System Role and Downtime Impact

The EPCPCRA#136 B5 is almost certainly a custom-designed board developed for a specific machine or subsystem where commercial controllers were either too costly, too slow, or lacked required integration features. Common applications include:

- High-speed packaging line coordinators

- Test bench sequencers in automotive/aerospace

- Custom robotics or material handling logic

- Legacy retrofit interfaces between modern HMIs and older PLCs

Because it is not a standard product, no direct replacement exists. If the board fails due to power surge, component aging, or firmware corruption, the host system may become completely inoperable. Unlike modular PLC systems, there is no catalog-based substitute—making this a single point of failure with potentially severe production consequences.

Reliability Analysis and Common Failure Modes

Custom embedded boards often prioritize function over long-term serviceability. Expected failure modes include:

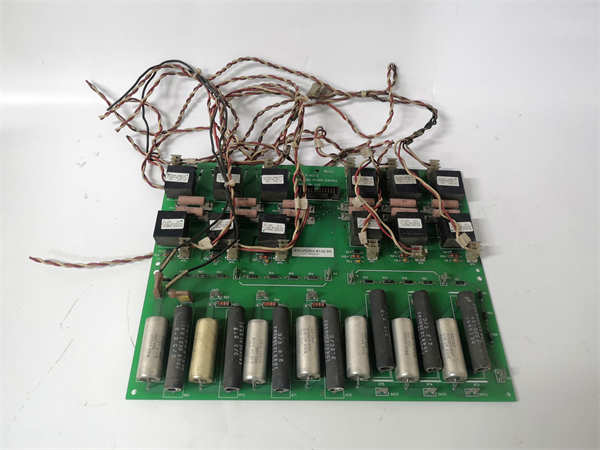

- Capacitor aging: Electrolytic capacitors on power rails dry out over time, causing voltage instability or brownouts

- Firmware loss: Battery-backed SRAM or flash memory corruption can brick the unit if calibration or boot code is lost

- Thermal fatigue: Repeated heating/cooling cycles crack solder joints—especially under large ICs or connectors

- I/O overvoltage: Lack of robust transient protection on field lines leads to damaged input buffers or communication transceivers

- Obsolescence lock-in: Use of discontinued ICs (e.g., legacy FPGAs or ASICs) makes board-level repair impractical

A major challenge is the lack of diagnostics—many such boards omit status LEDs or error logging to reduce cost. Troubleshooting often requires oscilloscope probing or behavioral inference.

🔧 Preventive Recommendations:

- Power via isolated 24 VDC supply with surge suppression

- Maintain ambient temperature <45°C to extend component life

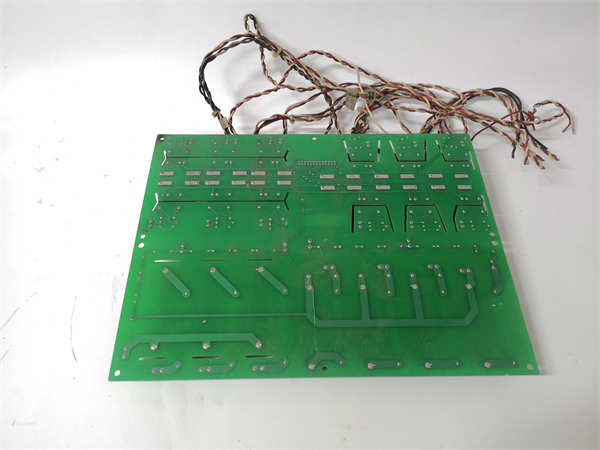

- Document all wiring before removal

- If operational, attempt to back up firmware via JTAG/SWD if headers are accessible

EMBEDDED EPCPCRA#136 B5

Lifecycle Status and Migration Strategy

This board exhibits classic signs of end-of-life proprietary hardware:

- No public datasheet or manufacturer support

- Part number format suggests internal OEM use (e.g., “EPC” = Embedded PC, “PRA” = possibly “Protocol Relay Adapter”)

- Revision “B5” implies prior reliability issues were addressed—but newer revisions are unavailable

Immediate Actions:

- Secure existing spares in ESD-safe, dry, temperature-controlled storage

- Photograph both sides of the PCB at high resolution for future reverse engineering

- Contact the original OEM—even if the machine is old, they may offer an upgrade kit or migration path

Long-Term Strategy: Functional Replacement

Since replication at the component level is rarely feasible, focus on functional equivalence:

- Analyze behavior: Use protocol analyzers (e.g., on RS-485 or CAN lines) to understand communication patterns

- Select modern platform: Replace with a flexible embedded controller such as:

- Beckhoff CX51xx (with TwinCAT)

- NI CompactRIO (with LabVIEW FPGA)

- Siemens SIMATIC IPC227E + S7-1200

- Raspberry Pi + industrial I/O HAT (for non-safety applications)

- Reimplement logic: Translate observed behavior into structured text (ST), ladder logic, or Python/C++

- Rewire field connections: Map original I/O to new terminals using terminal blocks or relays as needed

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: