Description

Technical Specifications (For Spare Parts Verification)

- Product Model: EPCDFBA#219 B2

- Manufacturer: Unknown / Proprietary (likely an internal part number from an OEM such as Siemens, Rockwell, or a machinery builder)

- System Platform: Not publicly documented; inferred to be part of a closed industrial control system

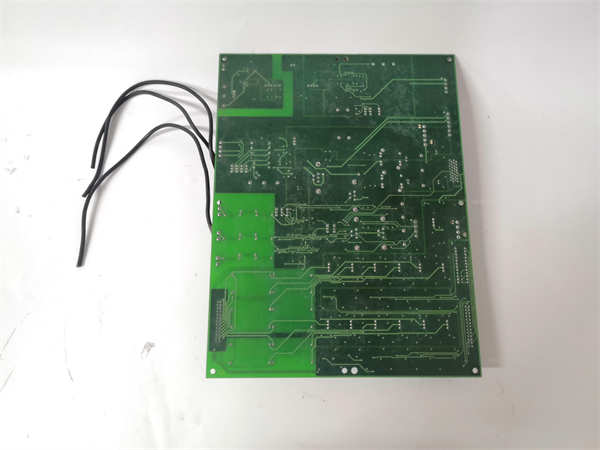

- Form Factor: Printed circuit board (PCB), revision B2 indicated by suffix

- Key Markings: “EPCDFBA#219 B2” silkscreened on board; may include unpopulated test points or JTAG headers

- Power Requirements: Undocumented; likely 5 VDC, 12 VDC, or 24 VDC based on industrial standards

- Interfaces: Unknown; possibly includes digital I/O, serial (RS-485/232), or fieldbus connections

- Programmable Elements: May contain FPGA, CPLD, or flash-based microcontroller requiring firmware image

- Operating Environment: Designed for industrial enclosure use (0–60°C typical)

- Regulatory Marks: Absence of CE, UL, or other visible certifications suggests internal-use-only design

System Role and Downtime Impact

The EPCDFBA#219 B2 appears to be a non-standard, application-specific embedded board, likely developed for a particular machine or subsystem where off-the-shelf controllers were unsuitable. Such boards are commonly found in legacy packaging lines, test rigs, or custom process skids. Its function could range from signal conditioning and protocol conversion to real-time motion sequencing.

Because it is not a catalog product, documentation and replacement paths are extremely limited. If this board fails—due to power surge, component aging, or firmware corruption—the entire host system may become inoperable. Unlike standard PLCs or I/O modules, there is no drop-in substitute. Recovery often requires either locating a verified spare (rare) or engaging in costly forensic analysis to replicate functionality. In production-critical environments, this poses a severe single-point-of-failure risk.

Reliability Analysis and Common Failure Modes

Custom embedded boards like the EPCDFBA#219 B2 often lack the rigorous design margins of commercial industrial products. Common failure mechanisms include:

- Electrolytic capacitor degradation on power rails, leading to brownouts or reset loops

- Firmware corruption in non-volatile memory due to incomplete writes or battery-backed SRAM failure

- Cold solder joints or trace cracks from thermal cycling, especially near high-power components

- ESD damage to unprotected I/O pins, particularly if used in harsh electrical environments

A critical vulnerability is the probable absence of diagnostic indicators—many custom boards omit LEDs or error codes to reduce cost. This makes troubleshooting reliant on oscilloscope-level probing or behavioral observation. Additionally, if the board contains a unique MAC address, encryption key, or calibration data stored in one-time-programmable memory, functional replication becomes significantly more complex.

Preventive recommendations include: powering the system through a clean UPS with surge protection, maintaining climate-controlled enclosures, documenting all wiring before removal, and—if possible—imaging any onboard flash memory while the unit is still operational.

EMBEDDED EPCDFBA#219 B2

Lifecycle Status and Migration Strategy

This component exhibits all hallmarks of an end-of-life proprietary module: no public datasheet, no manufacturer identification, and a part number format suggesting internal OEM use. It is almost certainly discontinued, with zero official support. Continued operation carries extreme risk—failure likely means extended downtime unless a spare exists.

Immediate actions should focus on preservation and reverse engineering:

- Secure any remaining spares in anti-static, dry storage

- Capture high-resolution images of both sides of the PCB for component mapping

- Attempt to back up firmware via JTAG or bootloader if accessible

- Consult the original equipment manufacturer (OEM) for upgrade kits—even if costly, they may offer a supported path

Long-term, the only sustainable solution is functional replacement. This typically involves:

- Reimplementing the board’s logic on a modern platform (e.g., CompactRIO, Beckhoff CX51xx, or Raspberry Pi with industrial HAT)

- Using protocol analyzers to understand its communication behavior and replicating it in software

- Rewiring field connections to a standard I/O system with equivalent response timing

While this requires upfront engineering investment, it eliminates dependency on undocumented, irreplaceable hardware and restores visibility, diagnostics, and cybersecurity compliance to the system.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: