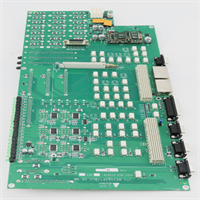

Description

Technical Specifications (For Spare Part Verification)

- Product Model: IB3111500

- Manufacturer: ELEMASTER

- System Compatibility: Designed as a third-party replacement for certain Triconex or legacy PLC I/O systems (exact compatibility must be verified per chassis and backplane protocol)

- Input Type: 16 channels, sinking (NPN-type), 24 VDC nominal

- Input Voltage Range: 15–30 VDC (ON state), <5 VDC (OFF state)

- Input Current: Approx. 7 mA per channel at 24 VDC

- Isolation: Channel-to-backplane isolation (typically 500 VDC, but varies by batch)

- Response Time: <5 ms (typical)

- Mounting: DIN rail or rack-mounted; physical dimensions: 120 mm H × 35 mm W × 100 mm D (verify against existing slot)

- Indicators: One LED per channel (green = active), one power/status LED

- Certification: May carry CE marking; original SIL certification (if any) is not transferable due to third-party origin

System Role and Downtime Impact

The ELEMASTER IB3111500 functions as a discrete input interface in industrial control or safety systems, commonly deployed in oil & gas, power, or chemical facilities where it reads binary signals from field devices such as shutdown valves, fire detectors, or motor status contacts. Although not part of a native TMR architecture like Triconex’s own modules, it is often found in hybrid or retrofitted systems where cost-driven I/O expansion was implemented using compatible third-party units.

If this module fails—due to input circuit damage, power loss, or communication dropout—the controller may lose visibility into critical process states. In a safety context, this could lead to an undetected fault condition (e.g., a valve reported as closed when it is actually open), potentially compromising a Safety Instrumented Function (SIF). In non-safety applications, it typically causes process alarms, automatic trips, or forced manual operation, often resulting in partial or full unit shutdown until the I/O is restored and signal integrity confirmed.

Reliability Analysis and Common Failure Modes

As a third-party I/O module from a now-inactive supplier, the IB3111500 lacks the rigorous design margins of OEM safety components. The most frequent failure mode is input optocoupler degradation, leading to intermittent signal dropout or complete channel failure—especially in high-EMI environments or when exposed to voltage transients from unshielded field wiring.

A key design weakness is the absence of robust surge suppression on individual channels. Unlike certified safety I/O, many IB3111500 units rely solely on basic TVS diodes, making them vulnerable to lightning-induced surges or inductive kickback from nearby solenoids. Additionally, the power regulation circuitry on older batches tends to use electrolytic capacitors that dry out over time, causing brownout resets or erratic behavior after 10+ years of service.

Preventive maintenance recommendations include:

- Inspecting terminal blocks for corrosion or loose connections, which can cause false OFF states

- Verifying that all field sources are sourcing-type (PNP) to match the module’s sinking input requirement

- Installing external surge protection (e.g., Phoenix Contact VAL-MB/T1+) on multi-wire trunk cables

- Monitoring channel LEDs during routine rounds for flickering or dim illumination, indicating early optocoupler wear

ELEMASTER IB3111500

Lifecycle Status and Migration Strategy

ELEMASTER ceased operations years ago, and the IB3111500 has been obsolete for over a decade. No official support, firmware updates, or manufacturing data exist. Remaining units are exclusively from surplus or broker inventories, with no guarantee of authenticity, burn-in testing, or prior usage history. Using such modules in safety-critical roles introduces unquantifiable risk and may violate IEC 61511 compliance requirements.

Short-term mitigation options include:

- Acquiring multiple verified units now for strategic spares, accompanied by full functional test reports

- Implementing redundant signal paths where feasible (e.g., dual-channel voting via logic solver)

- Restricting use to non-SIL, non-critical monitoring functions only

For sustainable operation, migration to a supported platform is strongly advised. Recommended paths include:

- Replacing the entire I/O subsystem with Triconex 3503E (16-channel isolated digital input, SIL 3 certified) if operating within a Tricon system

- Migrating to Rockwell GuardLogix 5580 with 1756-IB16I modules for integrated safety and standard control

- Adopting Schneider Electric Modicon X80 with TM3DI16L for cost-effective discrete I/O in non-safety applications

Any migration requires re-engineering of wiring, updating of logic programs, and re-validation of affected functions. Given the age and origin of the IB3111500, treating it as a temporary liability—not a long-term solution—is essential for operational integrity.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: