Description

Technical Specifications (For Spare Parts Verification)

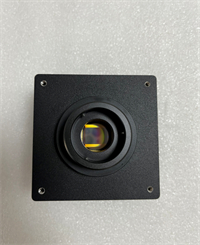

- Product Model: IB3110551

- Manufacturer: ELEMASTER S.p.A. (Italy)

- System Family: ELEMASTER EM-200/300 modular PLC series (1980s–1990s)

- Output Type: Sourcing (PNP-style), 24 VDC nominal

- Number of Channels: 16 isolated outputs

- Output Voltage Range: 20–30 VDC (derived from external 24 VDC supply)

- Output Current per Channel: Typically 0.5 A max (verify with original documentation)

- Isolation: Optical isolation between logic and field sides

- Mounting: Slide-in module with removable screw-terminal block

- Status Indication: Per-channel LED (usually red or green)

- Backplane Interface: Proprietary parallel bus to CPU (non-standard, system-specific)

System Role and Downtime Impact

The IB3110551 served as a key output module in ELEMASTER-based control panels across European industrial sectors, including packaging, textile machinery, and small assembly lines. It directly energizes field actuators such as pilot relays, solenoid valves, and motor contactor coils. In these legacy systems—often kept running due to mechanical longevity—the output module is rarely redundant. A failure (e.g., shorted transistor, open driver, or loss of backplane communication) results in loss of control over critical functions: a valve may not open, a conveyor may not start, or an alarm may remain silent during a fault. Because no new hardware is available and software tools are obsolete, recovery depends entirely on spare part availability, making this module a single point of failure with high operational risk.

Reliability Analysis and Common Failure Modes

Although built with industrial-grade components, the IB3110551 is now well beyond its intended service life. The most prevalent failure mode is output transistor burnout, often caused by inductive kickback from unshielded solenoids or relays lacking flyback diodes. This can result in a permanently “ON” or “OFF” state, or complete channel failure.

Additional issues include PCB trace corrosion near high-current paths, degraded optocouplers leading to logic-field decoupling, and terminal block loosening due to thermal expansion cycles over decades. The module provides no short-circuit protection per channel, so a single field fault can cascade into multiple output failures.

A fundamental design constraint is the lack of diagnostic feedback—beyond basic LEDs—making it difficult to distinguish between a module fault and a field wiring issue. Moreover, the proprietary backplane protocol prevents integration with modern I/O systems without full controller replacement.

Preventive maintenance guidance includes:

- Verifying that all connected inductive loads have suppression diodes installed

- Measuring output voltage under load during routine checks to detect droop or instability

- Inspecting terminal blocks for signs of arcing, discoloration, or oxidation

- Maintaining at least one fully tested spare unit with matching hardware revision

ELEMASTER IB3110551

Lifecycle Status and Migration Strategy

ELEMASTER ceased operations in the late 1990s, and no formal migration path exists for its hardware. The IB3110551 has been out of production for over 25 years, with no official support, firmware, or documentation from any successor entity. Continued reliance on this module represents a significant operational vulnerability.

Short-term risk mitigation options include:

- Commissioning board-level repair by specialized industrial electronics labs (e.g., replacing failed transistors or optocouplers)

- Installing external interposing relays to isolate the aging output stage from inductive loads

- Creating a functional replica using a modern micro-PLC with discrete outputs, wired in parallel to emulate original behavior (requires careful validation)

For sustainable operation, a full control system upgrade is strongly advised. Industry-standard replacements include:

- Siemens SIMATIC S7-1200 with SM1222 DO 16x24VDC/0.5A

- Allen-Bradley Micro850 with 1769-OB16

- WAGO PFC100 with 750-517 digital output modules

Migration entails re-engineering I/O wiring, rewriting control logic, and revalidating safety circuits—but eliminates dependency on an unsupported platform and enhances long-term maintainability, diagnostics, and cybersecurity posture. For facilities with budget constraints, prioritizing replacement on highest-risk machines offers a balanced approach to obsolescence management.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: