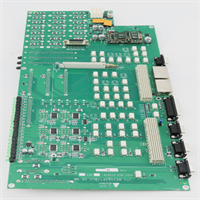

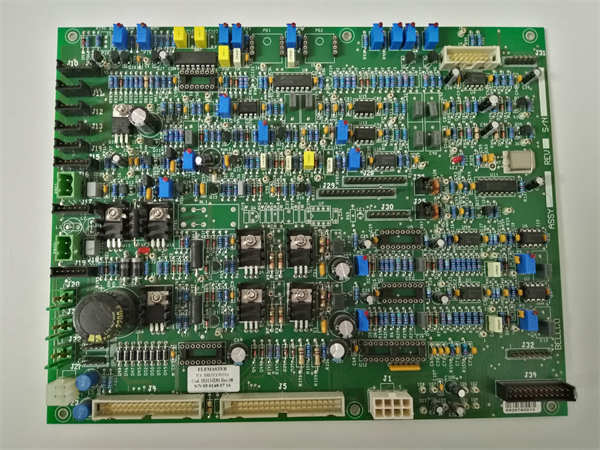

Description

Technical Specifications (For Spare Parts Verification)

- Product Model: IB3110250

- Manufacturer: ELEMASTER S.p.A. (Italy)

- System Family: ELEMASTER EM-200/300 modular PLC series (1980s–1990s)

- Input Type: Differential or single-ended analog inputs

- Number of Channels: Typically 4 or 8 (verify via label or original documentation)

- Supported Signal Ranges:

- 4–20 mA (most common, loop-powered or externally powered)

- 0–20 mA

- 0–10 VDC (less common, depends on variant)

- Input Impedance: ~250 Ω for current inputs

- Resolution: Likely 12-bit (typical for era)

- Isolation: Channel-to-backplane isolation via optocouplers or isolation amplifiers

- Mounting: Slide-in module with removable screw-terminal block

- Status Indication: Power LED; no per-channel diagnostics

- Backplane Interface: Proprietary parallel bus to CPU (non-standard protocol)

System Role and Downtime Impact

The IB3110250 was a foundational component in ELEMASTER-based process control panels used across European light industry, HVAC, water treatment, and small-scale manufacturing. It digitizes analog signals from transmitters—such as pressure sensors, RTDs with transducers, or flow meters—and delivers them to the PLC for closed-loop control or monitoring. In these aging systems, the module is rarely duplicated or redundant. A failure (e.g., due to ADC drift, channel burnout, or communication loss) results in invalid or frozen process values, which can cause:

- PID loops to saturate or oscillate

- Safety interlocks to trigger falsely (e.g., “high pressure” fault from open circuit)

- Batch processes to deviate from recipe specifications

Because the system lacks modern diagnostic capabilities, such failures may go undetected until quality or safety incidents occur.

Reliability Analysis and Common Failure Modes

After 30+ years in service, the IB3110250 is highly susceptible to component aging. The most common failure mode is analog front-end degradation, particularly in the precision resistors and isolation amplifiers that condition the 4–20 mA signal. This leads to gain drift, offset errors, or complete channel dropout.

Other frequent issues include:

- Electrolytic capacitor drying in power filtering circuits, causing noise or instability

- Cold solder joints on high-impedance analog traces, resulting in intermittent readings

- Lightning or surge damage from unprotected field wiring—especially problematic as the module lacks built-in transient suppression

A key design limitation is the absence of per-channel diagnostics or calibration memory. Calibration—if performed—was typically done manually via potentiometers or software offsets in the (now obsolete) programming environment. Additionally, the proprietary backplane interface prevents substitution with modern analog I/O without full system replacement.

Preventive maintenance recommendations include:

- Periodically injecting known test signals (e.g., 4 mA, 12 mA, 20 mA) and verifying PLC readings

- Inspecting terminal blocks for corrosion, especially in humid environments

- Ensuring all field transmitters are properly grounded and shielded

- Storing a verified spare unit with documented calibration data (if possible)

ELEMASTER IB3110250

Lifecycle Status and Migration Strategy

ELEMASTER ceased operations in the late 1990s, and no successor company maintains support for its hardware. The IB3110250 has been obsolete for over two decades, with no new units, firmware, or official documentation available. Continued use poses significant operational and compliance risks, particularly in regulated industries.

Short-term mitigation options include:

- Engaging specialized industrial repair services for board-level restoration and recalibration

- Installing external signal conditioners or isolators to protect the aging module

- Using a modern micro-PLC (e.g., Siemens LOGO! AM2, WAGO 750-460) as a “shadow” analog acquisition unit, feeding data via discrete emulation or serial link (complex but feasible for critical points)

Long-term, a full migration to a contemporary control platform is essential. Recommended replacements include:

- Siemens SIMATIC S7-1200 with SM1231 AI 4×13-bit (for 4–20 mA)

- Allen-Bradley Micro850 with 1769-IF4

- AutomationDirect DirectLOGIC DL06 with D0-04AD

- WAGO PFC100 with 750-460 4-channel analog input modules

Migration requires re-engineering field wiring, updating control logic, and revalidating process responses—but delivers improved accuracy, diagnostics, cybersecurity, and long-term supportability. For facilities managing multiple legacy lines, prioritizing systems with safety-critical analog inputs ensures maximum risk reduction per investment.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: