Description

Technical Specifications (For Spare Parts Verification)

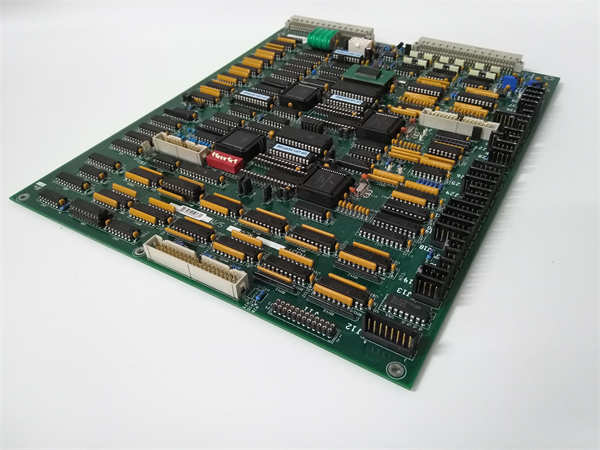

- Product Model: IB3110050

- Manufacturer: ELEMASTER S.p.A. (Italy)

- System Family: ELEMASTER modular PLC series (e.g., EM-200/300 platforms, circa 1980s–1990s)

- Input Type: Sinking (NPN-compatible), 24 VDC nominal

- Number of Channels: 16 isolated digital inputs

- Input Voltage Range: 15–30 VDC

- Input Current: Approximately 4 mA per channel at 24 VDC

- Isolation: Optical isolation between field side and internal logic

- Mounting: Slide-in or DIN-rail mounted module with removable terminal block

- Status Indication: Individual LED per channel (typically red or green)

- Backplane Communication: Proprietary parallel bus to CPU (non-standard protocol)

System Role and Downtime Impact

The IB3110050 was a standard digital input module in ELEMASTER-based control panels widely deployed in European manufacturing, packaging, and small-scale process machinery during the 1980s and 1990s. It directly connects to field devices such as door interlocks, position sensors, and emergency stop circuits, providing real-time status to the central CPU. In these legacy systems—often still operational due to robust mechanical design—the IB3110050 is typically not redundant. A failure (e.g., due to channel burnout or communication loss) can cause the PLC to read incorrect machine states, leading to incomplete cycles, safety lockouts, or uncontrolled motion. Because replacement logic hardware is unavailable, a single failed module can result in extended, unplanned downtime until a verified spare is sourced.

Reliability Analysis and Common Failure Modes

Many IB3110050 modules remain in service due to their simple, solid-state design with minimal components. However, after 30+ years of operation, several age-related failure mechanisms are common. The most frequent issue is optocoupler degradation on individual input channels, caused by repeated exposure to inductive loads without adequate flyback protection. This leads to “stuck” inputs (always ON or OFF) or intermittent signal dropout.

Secondary failure modes include terminal block corrosion (especially in humid or washdown environments) and cold solder joints on the PCB due to thermal cycling over decades. The module lacks built-in surge suppression, making it vulnerable to voltage transients from nearby motor starters or welding equipment.

A key design limitation is the proprietary backplane interface, which prevents substitution with modern I/O modules without complete system overhaul. Additionally, the absence of diagnostic data beyond basic LEDs complicates troubleshooting.

Preventive maintenance recommendations include:

- Inspecting wiring terminals for oxidation or looseness during scheduled stops

- Testing each input under load using a known-good 24 VDC source

- Verifying that all connected field devices include suppression diodes or RC snubbers

- Maintaining at least one tested spare unit in dry, temperature-controlled storage

IB3110050 ELEMASTER

Lifecycle Status and Migration Strategy

ELEMASTER as a brand ceased operations in the late 1990s, and its product lines were not formally migrated by any successor company. No official support, documentation, or new units exist. Continued use of systems containing the IB3110050 carries extreme risk: failure rates rise with age, and verified spares are increasingly scarce.

Temporary mitigation strategies include:

- Engaging specialized industrial electronics repair services for component-level restoration (e.g., optocoupler replacement)

- Building a functional clone using a modern micro-PLC (e.g., Siemens LOGO!, WAGO PFC100) to emulate input behavior—though this requires custom interfacing and validation

- Implementing external relay-based signal buffering to reduce stress on the original module

The only sustainable long-term solution is full control system replacement. Recommended migration paths include:

- Siemens SIMATIC S7-1200 with SM1221 DI 16x24VDC

- Allen-Bradley Micro850 with 1769-IA16

- AutomationDirect DirectLOGIC DL06 with D0-16ND

Such a project involves re-engineering I/O wiring, rewriting ladder logic, and revalidating safety functions—but eliminates dependency on an unsupported, high-risk platform. For heritage machinery where budget is constrained, a phased approach—starting with critical cells—is often the most pragmatic path forward.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: