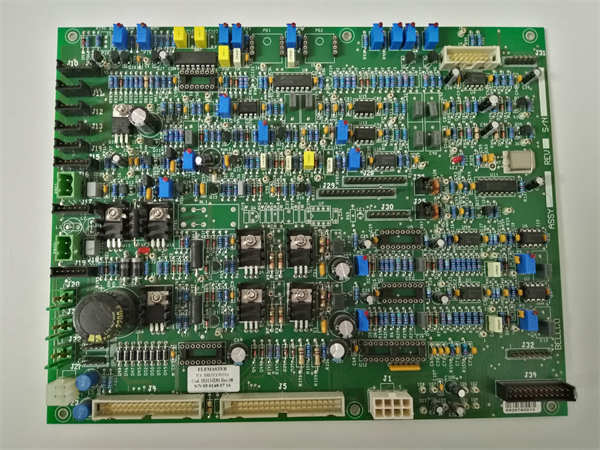

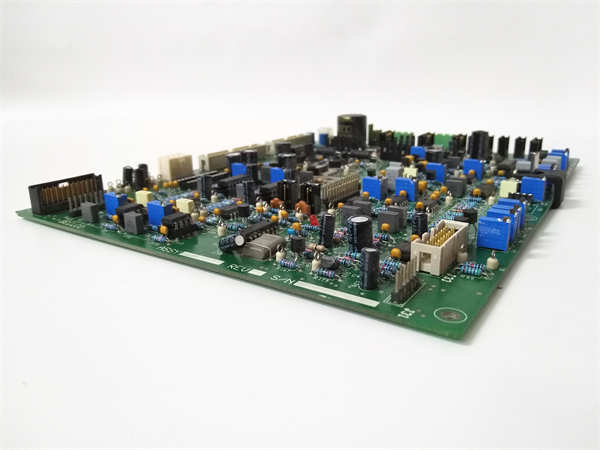

Description

Key Technical Specifications (For Spare Verification)

- Product Model: 3110250

- Manufacturer: ELEMASTER

- System Family: General industrial automation and machinery control

- Input Voltage: 85–264 VAC, 47–63 Hz (universal input range)

- Output Voltage: 24 VDC ±2%

- Rated Output Current: 10 A continuous

- Maximum Output Power: 240 W

- Inrush Current: Limited via NTC thermistor (typical <30 A at 230 VAC)

- Mounting Type: Standard 35 mm DIN rail (TS35/7.5 or TS35/15)

- Protection Features: Automatic recovery from overload, overvoltage, and short-circuit conditions

- Terminal Type: Screw-clamp terminals (typically 2.5–6 mm² wire capacity)

- Operating Temperature: -10°C to +60°C (derating required above 45°C ambient)

System Role and Downtime Impact

The ELEMASTER 3110250 typically serves as the main power source in control cabinets for packaging machines, material handling systems, and process skids installed between the late 1990s and mid-2000s. It powers multiple loads simultaneously—PLC CPUs, digital and analog I/O modules, relay banks, and solenoid valves. Due to its 10 A rating, it often supports entire sub-systems rather than single devices. In non-redundant installations, which are standard for this class of equipment, a failure leads to immediate and total loss of 24 VDC control power. This triggers emergency stops, disables safety interlocks, and halts automated sequences. Recovery time depends entirely on spare availability; without a verified replacement on hand, downtime can extend beyond 48 hours, especially in remote facilities.

Reliability Analysis and Common Failure Modes

Like most switch-mode power supplies of its era, the 3110250 relies heavily on aluminum electrolytic capacitors for output filtering and energy storage. These components degrade over time due to thermal stress, leading to increased equivalent series resistance (ESR) and reduced capacitance. The most common symptom is a gradual drop in output voltage under load, causing intermittent PLC faults or erratic actuator behavior before complete failure. Other frequent issues include:

- Open-circuit failures in the primary-side switching transistor due to voltage spikes

- Corrosion or loosening of screw terminals from vibration and thermal cycling

- Degraded varistors after repeated exposure to line surges, reducing surge immunity

A key design limitation is the absence of status signaling (e.g., DC OK relay contact), making predictive maintenance difficult. Additionally, the unit lacks active power factor correction, increasing sensitivity to poor power quality.

Recommended preventive actions include: annual thermal imaging of the unit during operation, visual inspection for bulging or leaking capacitors, torque verification of terminal screws, and periodic load testing using a dummy resistive load to confirm stable 24 VDC output at 8–10 A.

ELEMASTER IB3110250

Lifecycle Status and Migration Strategy

ELEMASTER no longer exists as an active brand in industrial power supply markets, and the 3110250 has been obsolete for more than 10 years. There is no official successor from the original manufacturer. Continuing to rely on this unit introduces significant operational risk: genuine new-old-stock is exhausted, and used units may have already surpassed their designed service life (typically 50,000 hours at 40°C). Counterfeit or reconditioned units with unverified performance are increasingly prevalent.

As a short-term measure, only functionally tested units from reputable industrial asset support providers should be considered—ideally those that perform 24-hour burn-in at full load and verify output stability across line and load variations.

For long-term reliability, direct replacement with modern equivalents is straightforward and highly recommended. Suitable drop-in alternatives include:

- Phoenix Contact QUINT-PS/1AC/24DC/10 – offers higher efficiency (>90%), built-in DC OK signaling, and superior surge immunity (up to 6 kV)

- Weidmüller PRO ECO 24V 10A – similar mechanical footprint, improved thermal performance

- Mean Well LRS-350-24 – cost-effective option, but verify depth and terminal spacing for panel fit

Migration requires only electrical and mechanical validation—no software changes or system reconfiguration. Given the low implementation effort and high risk mitigation value, proactive replacement is considered best practice for critical or high-utilization assets. Until then, maintaining at least one validated spare per site is essential for minimizing unplanned downtime.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: