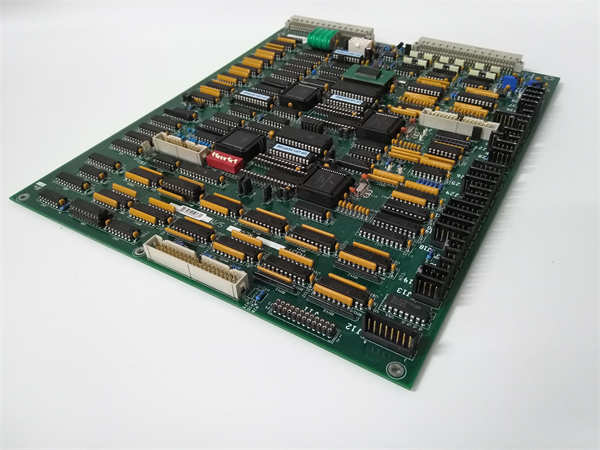

Description

Key Technical Specifications (For Spare Verification)

- Product Model: 3110050

- Manufacturer: ELEMASTER (historically associated with European industrial automation, later absorbed into broader distribution networks)

- System Family: General-purpose industrial control infrastructure

- Input Voltage: 85–264 VAC, 47–63 Hz (universal input)

- Output Voltage: 24 VDC ±2%

- Rated Output Current: 5 A continuous

- Peak Current Capability: Typically 150% for short duration (e.g., 5 seconds)

- Efficiency: Approximately 85% at full load

- Mounting Type: Standard 35 mm DIN rail (TS35/7.5 or TS35/15 compatible)

- Protection Features: Overload, overvoltage, and short-circuit protection with auto-recovery

- Terminal Type: Screw-clamp terminals for input and output

- Operating Temperature: -10°C to +60°C (derating above 45°C)

System Role and Downtime Impact

The ELEMASTER 3110050 is commonly found in mid-2000s European machinery and process control panels as the main 24 VDC power source for control logic. It typically powers PLC CPU modules, digital I/O cards, contactor coils, and safety relays. In non-redundant configurations—which represent the majority of installations—failure of this unit results in immediate loss of control voltage, causing machines to halt and safety circuits to de-energize. While not always tied to a single high-value asset, its failure can cascade across multiple stations in an assembly line or batch process, leading to unplanned downtime ranging from hours to days, depending on spare availability. Given its generic appearance, it is often misidentified as a “standard” component, delaying correct replacement.

Reliability Analysis and Common Failure Modes

This power supply follows a conventional flyback topology with electrolytic capacitors as the primary wear-out components. The most prevalent failure mode is gradual output voltage drop due to capacitor aging, especially in environments with elevated ambient temperatures or poor cabinet ventilation. This often manifests as intermittent PLC resets or erratic sensor behavior before complete shutdown. Secondary failure points include cracked solder joints on high-current terminals (from thermal cycling) and degraded varistors after repeated surge events.

A design limitation is the absence of remote monitoring or health signaling—users only detect failure after downstream devices lose power. Additionally, the unit lacks active power factor correction, making it more susceptible to instability on weak grids.

Preventive maintenance should include annual infrared thermography to identify hot spots, visual inspection for bulging capacitors or discolored PCB areas, and periodic measurement of no-load and loaded output voltage. In critical applications, adding a redundant supply (even from a different brand) with diode coupling is a cost-effective mitigation.

IB3110050 ELEMASTER

Lifecycle Status and Migration Strategy

ELEMASTER as a standalone brand is no longer active in the industrial power market, and the 3110050 has been obsolete for over a decade. No official successor exists under the original brand, and GE, Siemens, or Phoenix Contact do not list it in cross-reference databases. Continuing to operate on this unit carries clear risks: genuine new-old-stock is exhausted, and used units may have already exceeded their designed service life. Counterfeit or re-marked units are increasingly common in online channels.

As an interim solution, verified tested-and-working units from specialized industrial surplus providers can be deployed, provided they undergo full-load validation (minimum 4-hour burn-in at 80% load). For long-term reliability, direct functional replacement with modern equivalents is strongly advised. Suitable drop-in alternatives include:

- Phoenix Contact QUINT-PS/1AC/24DC/5 (offers higher efficiency, signaling contacts, and better surge immunity)

- Weidmüller PRO ECO 24V 5A (DIN rail compatible, similar footprint)

- Mean Well LRS-150-24 (cost-effective, but verify terminal spacing and depth)

Migration requires only mechanical and electrical verification—no software or configuration changes—making it one of the lowest-risk obsolescence mitigations in industrial control. Until replacement is executed, maintaining at least one validated spare per facility is essential for operational continuity.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: