Description

Key Technical Specifications (for Spare Verification)

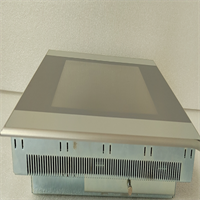

- Product Model: XVS-430-10MPI-1-10

- Manufacturer: Eaton

- Display Size: 10.4 inches

- Display Type: TFT color LCD, 640 × 480 resolution

- Touch Technology: Resistive touchscreen

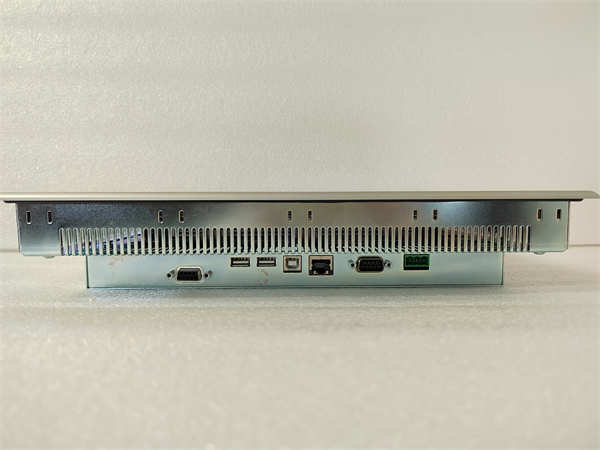

- Communication Interface: MPI (Multi-Point Interface) for direct connection to Siemens S7-300/400 CPUs

- Programming Software: Eaton XVIA Designer (based on CoDeSys environment)

- Power Supply: 24 VDC ±15%

- Operating Temperature: 0°C to +50°C

- Mounting Type: Panel mount (standard cutout dimensions required)

- Firmware Dependency: Requires matching project file compiled for XVS-430 hardware platform

System Role and Downtime Impact

The XVS-430-10MPI-1-10 serves as the central operator interface in older industrial systems built around Siemens S7-300 or S7-400 controllers, commonly found in water treatment plants, packaging lines, and material handling systems. Its MPI interface allows direct, protocol-native communication without gateways, simplifying integration but creating tight coupling to the PLC architecture. If this HMI fails—due to display burn-in, touchscreen unresponsiveness, or MPI port damage—operators lose real-time process visualization, alarm acknowledgment capability, and manual override functions. In many installations, there is no redundant HMI, making this a single point of failure that can halt production or force operation into unsafe manual bypass modes. Given its role in both efficiency and safety, unplanned downtime directly impacts operational continuity.

Reliability Analysis and Common Failure Modes

After 10–15 years of service, the XVS-430 exhibits predictable aging issues. The most frequent failures include:

- Backlight degradation or complete LCD failure due to thermal stress and component fatigue

- Resistive touchscreen wear, leading to calibration drift or dead zones from repeated use

- MPI communication chip failure, often triggered by ground loops or improper cable shielding in electrically noisy environments

- Internal power supply capacitor drying, causing spontaneous reboots or failure to power on

- Firmware corruption during unexpected power loss, especially if the unit lacks a clean shutdown sequence

The unit’s compact design limits internal airflow, making it susceptible to overheating in poorly ventilated enclosures. Additionally, the reliance on proprietary XVIA Designer software complicates recovery if the original project file is lost or incompatible with newer OS versions.

Recommended preventive actions include:

- Maintaining up-to-date backups of the HMI application project file and runtime image

- Using external cooling or cabinet air conditioning to reduce ambient temperature

- Inspecting MPI cabling for proper termination and shielding integrity

- Performing annual touchscreen calibration and display brightness checks

XVS-430-10MPI-1-10 EATON

Lifecycle Status and Migration Strategy

Eaton has discontinued the entire XVS series, with no direct replacement offered under the current product portfolio. Official technical support and software licenses for XVIA Designer are no longer available, increasing dependency on third-party specialists. Continuing to operate with this HMI carries growing risk due to hardware fragility and software obsolescence.

Short-term mitigation involves securing pre-tested, functionally verified spares that have undergone full display, touch, and MPI communication validation. Some users maintain a “hot spare” powered in standby to avoid cold-start capacitor issues.

For a sustainable solution, migration to a modern HMI platform is necessary. Recommended paths include:

- Siemens KTP700 Basic / KTP900 Comfort panels: Offer native MPI (via CP 5711 adapter) or PROFINET connectivity, with WinCC Advanced programming

- Eaton XV300 series: Current-generation HMIs supporting Modbus TCP, EtherNet/IP, and PROFINET, though MPI requires a gateway

- Open-platform HMIs (e.g., Weintek, Pro-face): Paired with an MPI-to-Ethernet converter (e.g., Helmholz NETLink PRO)

Migration requires re-engineering the visualization logic, but tools exist to partially convert XVIA projects. While this demands upfront engineering effort, it restores access to cybersecurity updates, remote diagnostics, and multi-protocol support—ensuring long-term operability and compliance with modern industrial standards.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: