Description

Key Technical Specifications (For Spare Parts Verification)

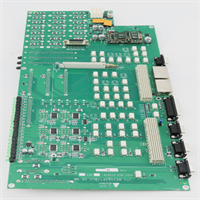

- Product Model: DPM-MC2

- Manufacturer: Eaton (formerly Cutler-Hammer)

- System Family: DPM (Digital Power Monitor) Series

- Application: Motor protection and control in MCCs and switchgear

- Protection Functions: Thermal overload, phase loss, phase reversal, ground fault, jam/stall, underload

- Current Input: 3-phase CT inputs (typically 1 A or 5 A secondary)

- Voltage Input: Optional 3-phase line voltage sensing (for power metering and undervoltage protection)

- Output Contacts: Multiple programmable relay outputs (e.g., trip, alarm, ready)

- Communication: Optional RS-485 (Modbus RTU) for remote monitoring

- Mounting: Standard 4-inch (101.6 mm) panel cutout or DIN rail adapter

- Power Supply: 120/240 VAC or 125 VDC auxiliary supply

System Role and Downtime Impact

The DPM-MC2 is typically installed as the primary protection device for critical motors in water treatment plants, HVAC systems, pumps, and compressors. It acts as the “last line of defense” between the motor starter and the driven load. If the DPM-MC2 fails—particularly in a stuck-closed or non-tripping state—the motor operates without protection. A minor fault such as single-phasing or mechanical jam can then escalate into complete stator winding failure, requiring weeks of repair and costing tens of thousands in equipment and downtime. In safety-critical applications, its failure may also violate OSHA or NFPA 70E compliance requirements for motor circuit protection. Given its role in preventing cascading damage, unplanned failure often triggers immediate operational shutdown until a verified replacement is installed.

Reliability Analysis and Common Failure Modes

The DPM-MC2, while robust for its era, exhibits age-related vulnerabilities common to early digital relays. The most frequent failure mode is power supply capacitor degradation, leading to intermittent resets, display flicker, or complete lockup. The opto-isolators on input/output circuits are also prone to drift over time, causing false tripping or failure to operate under fault conditions.

A key design limitation is the lack of modern cybersecurity features and limited self-diagnostics—unlike current-generation relays, it cannot report internal health status or log event sequences with millisecond resolution. Additionally, the display and keypad assembly often suffers from membrane fatigue or contact oxidation, making configuration changes difficult.

Recommended preventive maintenance includes: annually verifying trip settings using primary injection testing, inspecting terminal tightness and signs of overheating, checking auxiliary power stability, and ensuring firmware (if applicable) matches plant standards. Facilities should maintain at least one fully tested spare unit, stored in a dry, temperature-controlled environment to preserve internal electrolytics.

EATON DPM-MC2

Lifecycle Status and Migration Strategy

Eaton officially discontinued the DPM series in the late 2000s, with no direct drop-in replacement. Continued use poses growing risks: spare parts are scarce, technical documentation is archived, and the device lacks compatibility with modern asset management systems. Regulatory frameworks increasingly expect digital relays to support event recording and remote access—capabilities absent in the DPM-MC2.

As an interim measure, operators may source and functionally test surplus units or engage third-party services for board-level repair. However, this does not restore long-term reliability or compliance readiness.

Eaton’s recommended migration path is to replace the DPM-MC2 with the Power Xpert MC3000 or Intelligent Motor Control (IMC) series. These modern relays offer enhanced protection algorithms, built-in metering, Ethernet connectivity (Modbus TCP, IEC 61850), and integration with Eaton’s Power Xpert software for predictive maintenance. Migration requires updating the panel wiring (due to different terminal layouts) and reconfiguring protection settings, but retains the same form factor in many cases, minimizing enclosure modifications. For facilities planning broader electrical infrastructure upgrades, this transition aligns with industry best practices for resilience and digitalization.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: