Description

Key Technical Specifications (For Spare Parts Verification)

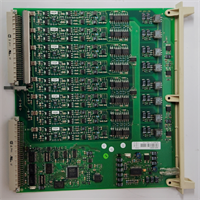

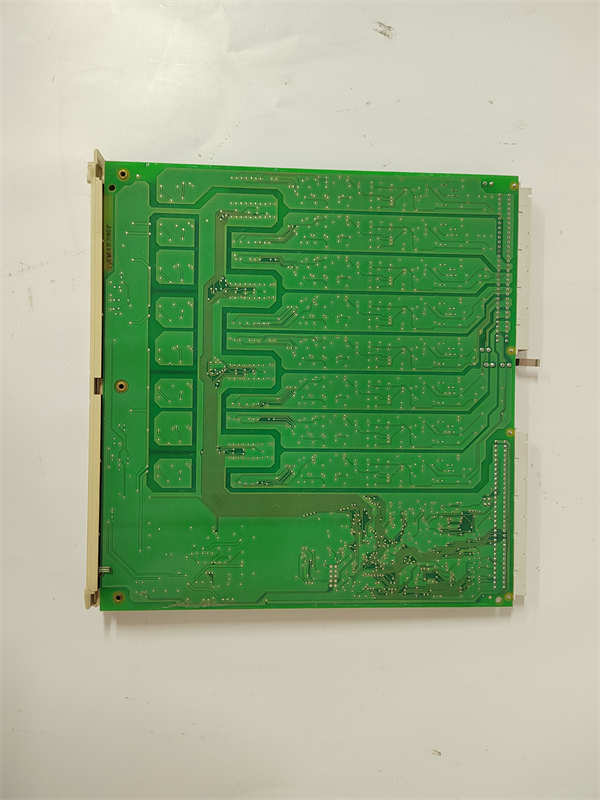

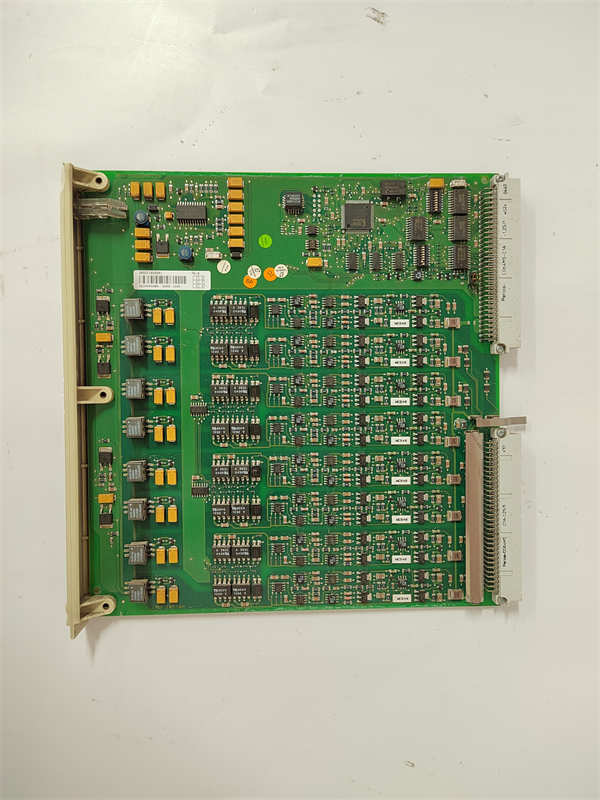

- Product Model: DSAO120A

- Order Code: 3BSE018293R1

- Manufacturer: ABB (Process Automation, now Hitachi Energy)

- System Platform: AC 800M Controller (used in Symphony Plus, Melody, and custom industrial automation systems)

- Output Channels: 8 independent analog outputs

- Signal Types: Selectable per channel – 0/4–20 mA or ±10 VDC

- Load Capability: 20 mA into 750 Ω (current mode); ±10 V into ≥ 2 kΩ (voltage mode)

- Accuracy: ±0.1% of full scale at 25°C

- Update Rate: Typically 10 ms per channel (system-dependent)

- Isolation: Channel-to-channel and field-to-logic isolation (≥ 500 VAC)

- Diagnostic Features: Per-channel open-circuit and short-circuit detection reported via Control Builder M

- Mounting: DIN rail with S800 I/O baseplate

- Operating Temperature: 0°C to +60°C

System Role and Downtime Impact

The DSAO120A is a foundational analog output interface in ABB AC 800M-based control systems deployed across power, water, mining, and chemical processing facilities. It converts digital setpoints from the controller into precise analog signals that drive critical field equipment—such as control valve positioners, variable frequency drives (VFDs), damper actuators, and generator excitation systems. Because these signals directly influence process variables like pressure, flow, temperature, and speed, any degradation or failure in the DSAO120A can lead to loss of regulatory control, process instability, or safety interlock bypass. In a boiler feedwater system, for example, a drifting or stuck output could cause drum level excursion, triggering a forced outage or, in extreme cases, equipment damage.

Reliability Analysis and Common Failure Modes

While designed for industrial environments, the DSAO120A exhibits predictable aging characteristics after 10+ years of continuous operation:

- DAC (Digital-to-Analog Converter) drift: The precision reference components in the output circuit degrade over time, causing channel offset or gain errors outside the ±0.1% specification—often undetected until calibration.

- Output driver failure: Semiconductor output stages can be damaged by sustained overloads, short circuits, or ground loops in field wiring, leading to zero output or saturation at rail voltage/current.

- Isolation barrier breakdown: Repeated exposure to high common-mode transients (e.g., from nearby motor starts) can compromise optocouplers or isolation amplifiers, risking backplane contamination.

- Connector and PCB corrosion: Humidity or chemical vapors in non-sealed cabinets accelerate oxidation on terminal blocks and PCB traces, increasing contact resistance and noise.

Recommended maintenance actions include:

- Performing annual loop calibration with documented as-found/as-left data.

- Verifying proper grounding of field device shields to avoid ground loops.

- Inspecting terminal blocks for signs of overheating or discoloration.

- Storing spare modules in dry, static-controlled environments and powering them quarterly to maintain component health.

DSAO120A 3BSE018293R1 ABB

Lifecycle Status and Migration Strategy

ABB (Hitachi Energy) has officially discontinued the DSAO120A as part of its hardware roadmap consolidation. No new units are manufactured, and OEM repair services are no longer available. Continued reliance on this module carries growing risk due to dwindling verified spares and rising costs in the secondary market.

Interim mitigation strategies:

- Procure only from vendors who perform full channel-level validation—including accuracy, load response, and diagnostic reporting—under simulated field conditions.

- Maintain calibrated spares with recent test certificates for rapid swap-out during failures.

- Consider external analog marshalling with modern signal conditioners to isolate legacy modules from harsh field loads.

Long-term migration path:

Hitachi Energy recommends replacing the DSAO120A with the DSAO122A (3BSE048712R1), a functionally equivalent module with extended lifecycle support, improved diagnostics, and enhanced noise immunity. This upgrade requires:

- Same S800 baseplate and field wiring.

- Minor configuration update in Control Builder M (module type change).

- No modification to control logic or HMI tags.

For facilities planning broader modernization, migration to the AC 900F platform or integration of remote I/O via PROFINET/Modbus TCP offers future-proofing. However, for most users, transitioning to the DSAO122A provides the most efficient path to restore reliability while preserving existing engineering investments.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: