Description

Key Technical Specifications (For Spare Parts Verification)

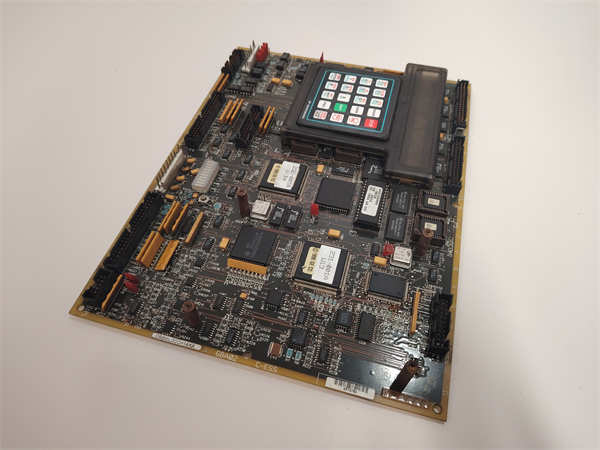

- Product Model: DS200LDCCH1AKA

- Manufacturer: General Electric

- System Family: Mark V Speedtronic™ turbine control system

- Board Type: LVDT/position feedback input interface

- Channels: Typically 4–8 differential LVDT inputs (verify via silkscreen or manual)

- Excitation Output: ~3–5 VAC RMS @ 2.5–3.5 kHz (for LVDT primary winding)

- Signal Conditioning: Built-in demodulation, filtering, and scaling to 0–10 V or 4–20 mA equivalent

- Backplane Interface: Connects to Mark V core rack via VME-style connector (DS200 backplane)

- Diagnostic Indicators: LEDs for power, channel status, and fault conditions

- Firmware/Revision: H1AKA suffix indicates specific hardware revision and calibration set

System Role and Downtime Impact

The DS200LDCCH1AKA is a critical analog input board within GE’s Mark V control architecture, widely deployed in gas and steam turbines for power generation and mechanical drive applications. It interfaces directly with Linear Variable Differential Transformers (LVDTs) mounted on fuel control valves, inlet guide vanes (IGVs), and other servo-actuated components. The board converts the AC-coupled LVDT output into a scaled DC signal representing precise mechanical position, which the Mark V controller uses for closed-loop regulation.

Because turbine control relies heavily on accurate real-time feedback, a malfunctioning LDCCH1AKA—due to signal drift, excitation loss, or internal fault—can cause unstable valve positioning, combustion anomalies, or automatic protective trips. In utility-scale operations, an unplanned turbine outage can result in revenue losses exceeding tens of thousands of dollars per hour and may affect grid reliability. Unlike digital I/O, analog feedback faults are often intermittent and difficult to diagnose without spare-board swap testing.

Reliability Analysis and Common Failure Modes

Despite robust industrial design, the DS200LDCCH1AKA is susceptible to age-related degradation due to its analog circuitry and continuous operation in high-temperature environments. The most common failure modes include:

- Excitation circuit failure: Aging oscillator components or transformer windings degrade, reducing or eliminating LVDT drive voltage—leading to “zero position” readings or erratic feedback.

- Capacitor drift: Electrolytic and film capacitors in the signal conditioning path lose tolerance over time, causing gain errors or noise susceptibility.

- Connector corrosion: The high-density backplane and terminal connectors are prone to oxidation in humid or salty environments, resulting in intermittent signals.

- Calibration shift: Factory calibration stored in potentiometers or trim networks can drift due to thermal cycling, requiring re-calibration against reference standards.

Design limitations include lack of self-diagnostics beyond basic LED indicators and no hot-swap capability. Preventive maintenance best practices include:

- Performing annual loop checks with calibrated LVDT simulators

- Verifying excitation voltage at terminal blocks during outages

- Cleaning backplane fingers and board edge connectors with contact enhancer

- Maintaining at least one fully tested spare with matching revision (H1AKA)

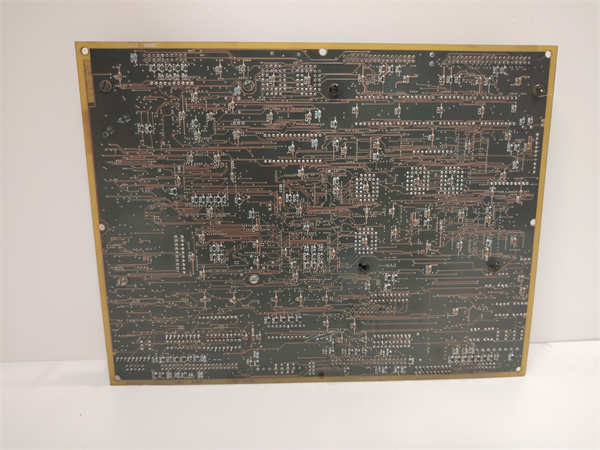

DS200LDCCH1AKA GE

Lifecycle Status and Migration Strategy

The DS200LDCCH1AKA is part of the Mark V platform, which GE has superseded with Mark VI and Mark VIe systems. While Mark V remains in service globally, GE (now part of Baker Hughes) no longer manufactures DS200-series boards. Official support is limited to extended repair services and surplus inventory, with lead times often exceeding 6–12 months for tested units.

Continued reliance on this module entails significant risk: counterfeit or misrepresented boards occasionally appear on the gray market, and untested spares may fail immediately upon installation.

Interim mitigation strategies include:

- Partnering with authorized service centers for board-level repair and recalibration

- Implementing redundant position sensing (where mechanically feasible)

- Archiving original calibration data and firmware settings

For long-term asset integrity, migration to Mark VIe is the recommended path. This involves:

- Replacing the entire control core (including I/O, controllers, and HMIs)

- Retaining existing field wiring through terminal block adapters

- Re-commissioning control logic using ToolboxST software

While costly, such upgrades deliver enhanced cybersecurity, remote diagnostics, and compatibility with modern plant-wide monitoring systems—transforming a legacy liability into a sustainable operational asset.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: