Description

Technical Specifications (For Spare Parts Verification)

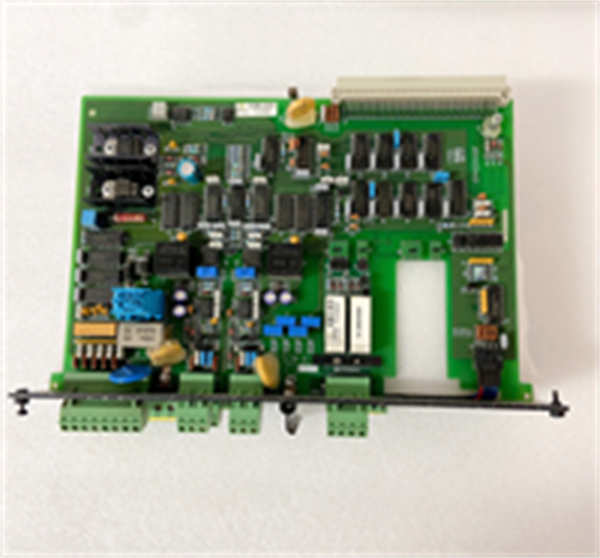

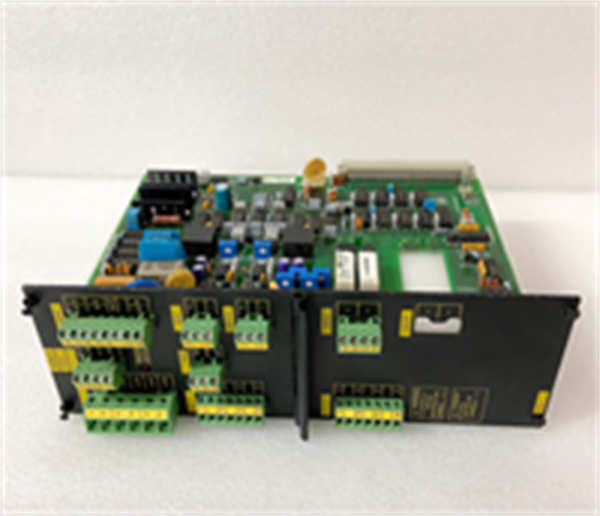

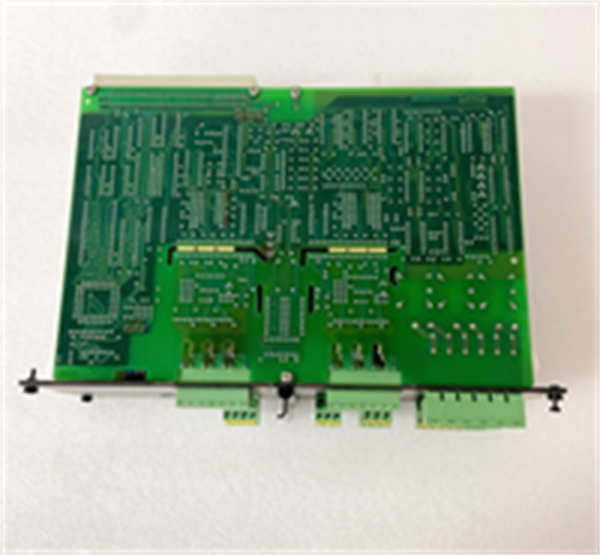

- Product Model: SCM-1

- Manufacturer: DEIF A/S

- Associated System: DEIF AGC/ASC legacy power management panels (pre-InteliSys era)

- Function Type: Synchronization and load sharing controller

- Input Signals: 3-phase voltage (PT), 3-phase current (CT), speed signal (magnetic pickup or frequency input)

- Output Relays: Sync OK, Close GCB, kW bias, kVAR bias (typically 4–6 SPDT relays)

- Control Method: Analog circuitry with potentiometer-based adjustment (no digital display)

- Mounting: Standard 19″ rack or panel mount, approx. 240 mm wide

- Power Supply: 24 VDC or 110/220 VAC (field-configurable via internal jumpers)

- Operating Temperature: -10°C to +55°C

- Compliance: IEC 60092 (marine), IEC 60255

System Role and Downtime Impact

The SCM-1 is typically installed in the control cabinet of marine vessel engine rooms or industrial standby power plants where multiple diesel generators must operate in parallel. It continuously compares voltage, frequency, and phase angle between an incoming generator and the live busbar, issuing a “Close GCB” command only when synchronization conditions are met. Simultaneously, it outputs analog bias signals to governor and AVR systems to balance real and reactive power among units. If the SCM-1 fails—due to component drift, relay contact welding, or power supply degradation—the entire paralleling sequence becomes unreliable. This can lead to either failed startups during load transfer or, worse, out-of-phase closing that causes severe mechanical torque spikes, potentially damaging crankshafts, couplings, or switchgear. On offshore platforms or passenger vessels, such a failure could result in total blackout, triggering safety-critical emergency procedures.

Reliability Analysis and Common Failure Modes

The SCM-1 relies heavily on discrete analog components—operational amplifiers, comparators, and electrolytic capacitors—which degrade predictably over time. The most common failure mode is capacitor drying-out, particularly in the timing and filtering circuits, leading to erratic sync pulses or unstable load sharing. A second frequent issue is relay contact oxidation or sticking, especially in high-humidity marine environments, causing false “Sync OK” signals or failure to issue close commands. Additionally, the internal adjustment potentiometers can develop intermittent connections due to vibration, resulting in drifting setpoints for droop or deadband.

A key design limitation is the absence of self-diagnostics or event logging. Unlike modern digital controllers, the SCM-1 provides no indication of why a sync attempt failed, forcing engineers to rely on oscilloscope measurements across test points—a time-consuming process during emergencies. Furthermore, its analog nature makes it sensitive to ground loops and EMI from nearby VFDs or radar systems.

Recommended preventive actions include:

- Annual calibration using a precision phase/frequency simulator to verify sync window accuracy

- Inspection of relay contacts for pitting or carbon buildup; clean or replace if resistance exceeds 100 mΩ

- Replacement of all electrolytic capacitors on units older than 12 years, regardless of apparent function

- Ensuring shielded cabling for PT/CT inputs with single-point grounding to minimize noise coupling

SCM-1 DEIF

Lifecycle Status and Migration Strategy

DEIF officially discontinued the SCM-1 more than 15 years ago, with full support sunset following the launch of the ASC-4 and InteliSys families. No firmware updates, repair services, or technical documentation are available from the manufacturer. Continued use exposes operators to escalating risks: untraceable spare parts, lack of compliance with modern marine regulations (e.g., IMO MEPC.1/Circ.873 on cyber resilience), and inability to integrate with fleet monitoring systems.

For vessels or plants unable to fund immediate panel replacement, two short-term options exist:

- Strategic sparing: Acquire and functionally test multiple SCM-1 units now to cover remaining operational life.

- Hybrid retrofit: Replace only the SCM-1 with a modern drop-in digital synchronizer (e.g., DEIF ASC-4 or InteliSys Basic) that mimics analog outputs, minimizing rewiring.

The recommended long-term path is a full migration to DEIF’s InteliSys N7 or Lite platform. This requires updating the generator control architecture but delivers significant benefits: automatic load sharing, blackout prevention logic, remote diagnostics via Modbus TCP, and compliance with IEC 61850-7-420 for microgrids. The migration scope should include revalidation of protection coordination and update of class society documentation (e.g., DNV, ABS, LR). Given the safety-critical nature of power management, delaying this transition increases both operational and regulatory exposure.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: