Description

Key Technical Specifications (For Spare Parts Verification)

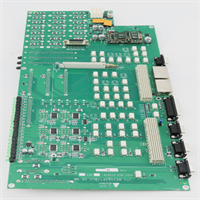

- Product Model: S20360-SRS

- Manufacturer: Danaher Motion

- Series: S200 Digital Servo Drive

- Continuous Current Output: 3.6 A

- Peak Current Output: Typically 7.2 A (2x continuous, duty-cycle dependent)

- Input Voltage Range: 20–80 VDC

- Feedback Interface: Supports incremental encoder (differential or single-ended)

- Communication Protocol: RS-485 (proprietary S200 command set)

- Control Modes: Torque, velocity, and position (via external motion controller)

- Mounting: Panel mount with heatsink requirement

- Firmware Version Dependency: Operation depends on specific firmware revision; mismatch can cause commutation errors

System Role and Impact of Failure

The S20360-SRS serves as the power and control interface between a motion controller (e.g., Danaher MV-series or third-party PLC with motion module) and a servo motor in applications such as packaging, printing, or material handling equipment. It interprets motion commands over RS-485 and delivers precisely timed current to the motor windings based on real-time encoder feedback. If this drive fails—due to power surge, overheating, or internal component degradation—the associated axis becomes inoperable. In tightly synchronized multi-axis machines (e.g., rotary fillers or web handling systems), a single drive fault often forces a complete line stoppage. Additionally, because the S200 series lacks modern safety protocols (e.g., STO), failure modes may not be safely contained, increasing mechanical or operator risk.

Reliability Analysis and Common Failure Modes

Many S20360-SRS units remain in service due to the long life of industrial machinery, but their age exposes several reliability concerns.

Common failure modes include:

- Failure of electrolytic capacitors in the DC bus circuit, leading to voltage ripple, erratic behavior, or complete shutdown.

- Burnout of output MOSFETs due to repeated overloads, short circuits, or inadequate heatsinking.

- Corrosion or cold solder joints on the PCB, especially around high-current traces, causing intermittent operation.

- Loss of encoder signal integrity due to degraded optocouplers or EMI susceptibility in older designs.

Design weaknesses include:

- Dependence on a single RS-485 communication link with no redundancy.

- Lack of built-in safe torque off (STO) or functional safety features.

- Firmware stored in non-volatile memory that can degrade over time, leading to boot failures.

- Sensitivity to supply voltage transients due to minimal input filtering.

Preventive maintenance recommendations:

- Inspect and clean heatsinks quarterly; verify ambient temperature stays below 45°C.

- Monitor DC bus voltage stability during operation using an oscilloscope to detect capacitor aging.

- Back up drive configuration parameters (gain settings, current limits) using legacy Danaher software (e.g., S200 Setup Tool).

- Maintain at least one tested spare drive with matching firmware version; power it up every 12 months to refresh components.

DANAHER S20360-SRS

Lifecycle Status and Migration Strategy

Danaher discontinued the S200 series in the mid-2000s. Official technical support, firmware updates, and repair services are no longer available. Continued use poses risks: inability to source reliable replacements, lack of cybersecurity or safety compliance for new installations, and growing difficulty in integrating with modern control architectures.

As a short-term measure, facilities can source used or refurbished S20360-SRS units, but each must be functionally tested under load and verified for firmware compatibility with the existing motion controller.

The recommended migration path is to replace the S20360-SRS with a Kollmorgen AKD-NB00306 or S300-3.6A drive, both of which offer:

- Equivalent or higher current rating in a compact form factor

- Support for EtherCAT, CANopen, or analog ±10V interfaces

- Integrated STO (Safe Torque Off) per IEC 61800-5-2

- Compatibility with modern motion controllers and HMI ecosystems

Migration requires:

- Replacing motor feedback cables if switching from incremental encoder to absolute (optional)

- Updating motion program logic to accommodate new drive command structure

- Re-tuning PID gains due to differences in current loop bandwidth

For cost-sensitive retrofits where full replacement is not feasible, third-party “form-fit-function” replacement drives with S200 protocol emulation are available from specialized motion integrators, though long-term support should be carefully evaluated.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: