Description

Key Technical Specifications (for Spare Part Verification)

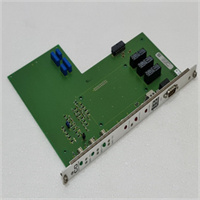

- Product Model: SC203-100A-002IR-010-01K-05

- Manufacturer: CTC / Parker Hannifin

- Product Family: SmartController™ SC200 series

- CPU Type: 32-bit RISC processor (proprietary architecture)

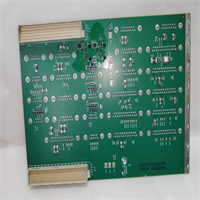

- Onboard I/O:

- 16 digital inputs (sinking/sourcing configurable)

- 8 high-speed digital outputs (typically 0.5 A @ 24 V DC)

- 2 analog inputs (0–10 V or 4–20 mA, via internal option)

- Motion Capability: Integrated stepper/servo pulse train output (PTO); supports up to 2 axes (depending on firmware)

- Communication Interfaces:

- RS-232/485 (Modbus RTU, CTC protocol)

- IR port (Infrared serial link—used for handheld programmer or legacy HMI interface; denoted by “IR” in model code)

- Memory: Battery-backed SRAM for program retention (~32 KB typical)

- Programming Software: CTC WorkShop™ (Windows-based; discontinued; incompatible with modern OS without virtualization)

- Power Supply: 24 V DC nominal input

- Mounting: DIN-rail mountable compact housing

- Real-Time Clock: Optional (often tied to battery backup)

System Role and Downtime Impact

The SC203-100A-002IR-010-01K-05 was widely deployed in mid-tier industrial machinery from the late 1990s through the early 2010s, particularly in applications requiring coordinated motion and discrete logic—such as label applicators, cartoners, fillers, and web handling systems. Its integrated design eliminated the need for separate PLC and motion controllers, reducing panel space and wiring complexity. The IR port enabled field technicians to upload/download programs or monitor status using a handheld terminal without physical cabling—a feature valued in washdown or confined environments. A failure of this unit typically results in complete machine stoppage, as it controls both sequencing logic and critical motion profiles. Because the firmware and configuration are stored in volatile memory backed by a lithium battery (with ~5–10 year life), units that lose power after battery depletion may require full reprogramming—a major challenge given the obsolescence of development tools.

Reliability Analysis and Common Failure Modes

After 10–20 years in service, the SC203 series exhibits several predictable failure mechanisms. The most critical is battery-backed SRAM corruption or loss, especially if the internal coin-cell battery was never replaced. This leads to blank programs on power-up, forcing reliance on archived backups—if available. The second common issue is degradation of the opto-isolators on digital I/O channels due to repeated inductive load switching, causing input misreads or output failures. The IR communication window can become obstructed by dust, oil film, or yellowing of the polycarbonate lens over time, rendering the infrared interface unusable. Additionally, the onboard switching regulator is prone to capacitor aging, resulting in unstable 5 V logic supply, intermittent resets, or failure to power up. Since the unit lacks modern self-diagnostics or Ethernet connectivity, fault isolation often requires substitution testing. Recommended practices include: maintaining a known-good spare with verified program backup, replacing the internal battery during preventive maintenance, cleaning the IR window annually, and storing unused units in dry, temperature-controlled environments.

-

CTC SC203-100A-002IR-010-01K-05

Lifecycle Status and Migration Strategy

CTC discontinued the SC200 series following its integration into Parker Hannifin’s automation portfolio, with no direct successor offering IR communication or identical form-fit-function. Official support, including CTC WorkShop software licenses and technical documentation, is no longer available. Continuing to operate on this platform carries significant risk: secondary market units may have unknown usage history, dead batteries, or corrupted memory; programming requires legacy Windows XP/7 systems running in isolated VMs; and cybersecurity is nonexistent. As an interim solution, users should:

- Archive all existing application files (.PRG, .CFG) using a legacy PC

- Maintain at least one fully functional spare with fresh battery

- Consider third-party reverse-engineering services to extract logic for migration

For long-term reliability, Parker Hannifin recommends transitioning to modern platforms such as the Parker PAC (Programmable Automation Controller) series or Trio Motion Controllers with CODESYS support. Alternatively, many integrators successfully migrate SC203 logic to compact PLCs like the Allen-Bradley Micro850, Siemens SIMATIC S7-1200, or Automation Direct Productivity2000, which offer superior I/O density, Ethernet/IP, data logging, and remote access. While not drop-in replacements, these solutions provide future-proofing, improved diagnostics, and compatibility with current engineering workflows. A phased migration—starting with non-critical machines—is advised to manage cost and risk.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: