Description

Technical Specifications (For Spare Parts Verification)

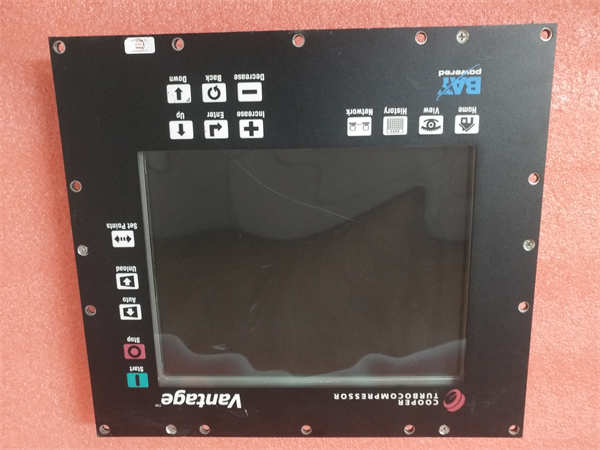

- Product Model: P3798102-00010 CN-UIM2

- Manufacturer: Cooper Power Systems (Eaton)

- Compatible Relay Families: CSPS, CEP, or early SEL-integrated platforms

- Form Factor: Plug-in module or DIN-rail mounted unit with removable connectors

- Primary Interface: RS-485 (Modbus RTU, DNP3.0) or 10BASE-T Ethernet (early TCP/IP stack)

- Baud Rate / Network Settings: Configurable via DIP switches or proprietary configuration software

- Power Supply: Typically 24–48 VDC or 120 VAC derived from relay auxiliary supply

- Diagnostic Indicators: LEDs for power, TX/RX activity, link status

- Mounting: Integrated into relay chassis or external enclosure

- Firmware Version: Fixed or upgradable via legacy PC tool (e.g., Cooper Relay Assistant)

- Physical Connectors: Screw terminals or RJ45/DB9 depending on variant

System Role and Downtime Impact

The CN-UIM2 module is typically installed within or adjacent to a protective relay panel in medium- or high-voltage substations, serving as the sole communication path between the relay and the central SCADA or substation automation system. It transmits critical data such as fault records, breaker status, metering values, and alarm flags. If this module fails, the relay continues to provide local protection but becomes “invisible” to operators—preventing remote tripping, masking developing faults, and delaying outage restoration. In unattended substations, this can lead to cascading failures or extended downtime during grid disturbances. Regulatory compliance (e.g., NERC CIP) may also be impacted due to loss of telemetry.

Reliability Analysis and Common Failure Modes

After 10–20 years of service in electrically noisy environments, the CN-UIM2 is prone to several failure mechanisms:

- Isolation barrier breakdown: Optocouplers or isolation transformers degrade, leading to ground loops or signal corruption on communication lines.

- Ethernet PHY chip failure: Early 10BASE-T components suffer from thermal stress or ESD damage, causing link drops or complete network loss.

- Configuration memory loss: Battery-backed SRAM or EEPROM corruption results in default or invalid IP/serial settings after power cycles.

- Connector corrosion: Terminal blocks or RJ45 jacks oxidize in humid environments, increasing contact resistance and causing intermittent comms.

A key design limitation is the dependency on obsolete PC-based configuration tools that are incompatible with modern Windows operating systems, complicating recovery if settings are lost. Additionally, many units lack surge protection on communication ports, making them vulnerable to lightning-induced transients on long cable runs.

Preventive maintenance should include:

- Verifying communication integrity during routine substation testing using protocol analyzers.

- Inspecting for discoloration or burnt smell near power regulation components.

- Backing up configuration files (if accessible) and documenting DIP switch settings.

- Installing external surge suppressors on all communication lines entering the substation.

Cooper P3798102-00010 CN-UIM2

Lifecycle Status and Migration Strategy

Eaton no longer manufactures or supports the CN-UIM2 module. While some third-party vendors offer refurbished units, their functional lifespan is uncertain, and firmware recovery options are extremely limited. Continued use poses operational and compliance risks, especially in regulated utility environments.

As a temporary measure:

- Identify and test all available spares using loopback diagnostics.

- Document physical and logical wiring to enable rapid swap-out.

- Consider external protocol gateways (e.g., Moxa, Westermo) to bridge legacy serial relays to modern Ethernet networks if the native UIM fails.

For long-term reliability, Eaton’s recommended migration path is upgrading to the Eaton IntelliRupter® PulseCloser® or Power Xpert® Protection Relays (e.g., PXM series), which feature:

- Native IEC 61850, Modbus TCP, and DNP3 over Ethernet

- Cybersecurity features (ACLs, TLS, user authentication)

- Web-based configuration and remote access

This transition typically requires relay replacement, re-engineering of I/O wiring, and SCADA database updates—but eliminates dependency on obsolete hardware and aligns the substation with modern grid automation standards. Facilities planning to operate beyond 2027 should initiate this upgrade during scheduled maintenance outages.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: