Description

Key Technical Specifications (For Spare Parts Verification)

- Product Model: 3701-55

- Manufacturer: Bently Nevada (Baker Hughes)

- System Platform: 3500 Machinery Protection System

- Module Type: Rack Interface Module (RIM)

- Communication Interfaces: RS-232/422/485 (for configuration), Modbus RTU (for host integration)

- Redundancy Support: Non-redundant (single-point-of-failure in standard configurations)

- Power Management: Monitors and reports on +24 VDC and ±12 VDC backplane supplies

- Diagnostic Features: Module OK status, power fault detection, communication error logging

- Mounting: Slot 1 (leftmost) in 3500 chassis (mandatory position)

- Firmware Dependency: Requires compatible 3500 framework software version

System Role and Downtime Impact

The 3701-55 is the foundational control and communication module in the Bently Nevada 3500 system. Installed in Slot 1 of every 3500 chassis, it enables configuration, data polling, and alarm transmission to higher-level systems such as plant DCS, HMI, or historian platforms. It also monitors internal power rails and reports faults that could affect other I/O modules (e.g., vibration input cards, relay output modules). Failure of the 3701-55 renders the entire 3500 rack inaccessible and non-functional, even if all other modules are operational. This results in complete loss of machinery protection—no vibration monitoring, no trip relay activation, no alarm annunciation—posing a severe risk to rotating equipment integrity. Replacement requires system shutdown, reconfiguration via Rack Configuration Software (RCS), and validation of communication links, all of which are critically dependent on spare part availability and legacy software compatibility.

Reliability Analysis and Common Failure Modes

Despite its robust industrial design, the 3701-55 is vulnerable due to its age (commonly deployed from late 1990s to mid-2000s) and central role. The most frequent failure modes include:

- Serial communication IC degradation, leading to intermittent or complete loss of Modbus/RS-485 connectivity with the host system—often misdiagnosed as cabling issues.

- Internal EEPROM corruption, causing the module to lose its configuration or fail to boot, especially after power cycling.

- Power monitoring circuit drift, resulting in false “power fault” alarms that disable the rack unnecessarily.

- Backplane connector oxidation or solder fatigue, creating intermittent contact that causes random rack resets or communication dropouts.

A critical design limitation is the lack of redundancy in standard 3500 installations; the RIM is a single point of failure. Preventive maintenance should include periodic verification of serial communication integrity, inspection of firmware version consistency, cleaning of chassis ventilation paths, and monitoring of power supply health logs from adjacent modules.

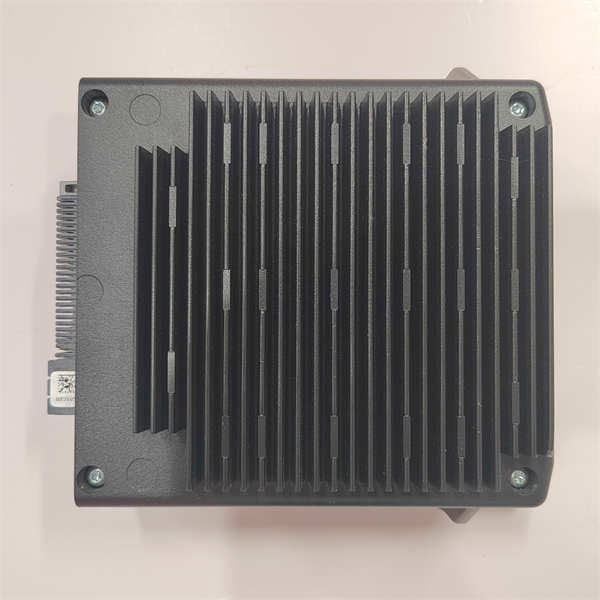

BENTLY NEVADA 3701-55

Lifecycle Status and Migration Strategy

Bently Nevada has discontinued the 3701-55 as part of the evolution toward the 3500/XXe platform (e.g., 3500/25e, 3500/45e), which features Ethernet-based communication, enhanced cybersecurity, and improved diagnostics. No new 3701-55 modules are available from the manufacturer. Continued operation carries significant risk: untested surplus units may exhibit latent firmware or hardware faults, and compatibility with modern Windows-based configuration tools (e.g., 3500 Rack Configuration Software on Windows 10/11) is increasingly problematic.

Short-term mitigation includes sourcing only from vendors providing full functional test reports—including Modbus polling validation and power fault simulation—and maintaining a verified spare in climate-controlled storage. Pre-installation testing in a bench rack is strongly advised.

The strategic long-term solution is migration to the 3500/XXe series, where the RIM function is replaced by the 3500/25e Communications Gateway or integrated into Ethernet-capable monitor modules. This upgrade enables:

- Native Ethernet (Modbus TCP, OPC UA) connectivity

- Secure remote access and firmware updates

- Seamless integration with modern asset performance management (APM) platforms

Migration typically requires chassis replacement or retrofit kits, updated configuration files, and re-commissioning of alarm/trip logic—but eliminates dependency on obsolete hardware and restores access to factory support, ensuring continued compliance with API 670 and other machinery protection standards for critical rotating assets.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: