Description

Key Technical Specifications (For Spare Part Verification)

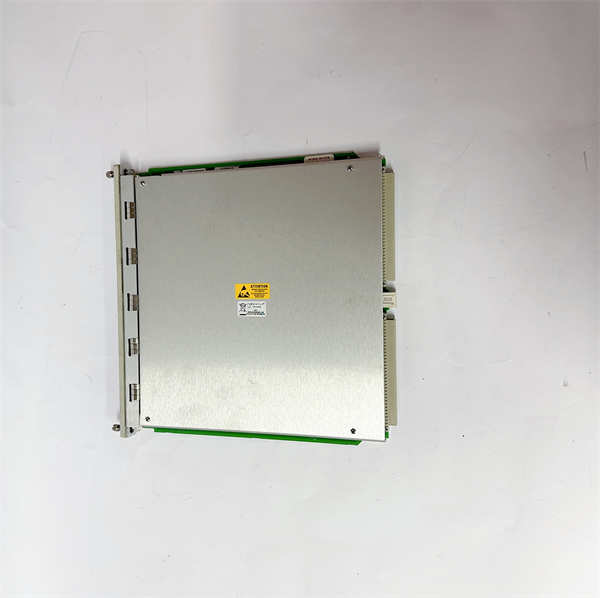

- Product Model: 3500/42M

- Manufacturer Part Number: 176449-02T

- Manufacturer: Bently Nevada (Baker Hughes)

- Product Family: 3500 Monitoring System

- Input Channels: 4 independent channels

- Sensor Compatibility: Bently Nevada proximity probes (e.g., 3300 XL), velocity sensors, or accelerometer inputs (with appropriate conditioner)

- Measurement Types: Radial vibration, axial thrust position, differential expansion, case expansion

- Output Options: Configurable alarm/trip relay logic, 4–20 mA analog outputs (per channel, if enabled)

- Frequency Range: DC to 1 kHz (standard); up to 2 kHz with high-frequency option

- Mounting: 3500 chassis backplane (4-slot height)

- Operating Temperature: 0°C to +65°C

- Compliance: CSA, CE, IEC 61010, API 670 compliant (as originally certified)

System Role and Downtime Impact

The 3500/42M is a foundational module in Bently Nevada’s 3500 machinery protection architecture, widely deployed in oil & gas, power generation, and petrochemical facilities. It continuously monitors dynamic mechanical behavior of high-value rotating assets and triggers protective actions—such as alarms or automatic shutdowns—when vibration or position thresholds are exceeded.

In critical service (e.g., a main boiler feed pump or a gas turbine driver), loss of this module can disable multiple protection loops simultaneously. If the system lacks redundancy or voting logic, failure may result in either a spurious trip (causing unplanned downtime) or, more dangerously, a failure-to-trip during an actual mechanical fault—risking catastrophic equipment damage, safety incidents, or environmental releases. Given its integration into plant-wide ESD systems, module unavailability often delays return-to-service after maintenance outages.

Reliability Analysis and Common Failure Modes

Despite rugged industrial design, units operating beyond 15–20 years show predictable degradation. The most frequent failure mode is drift in signal conditioning circuitry, particularly in the front-end amplifier stages that process low-level proximity probe signals (typically -2 to -18 V DC). This leads to false high-vibration readings or loss of valid data.

Other common issues include:

- Failing onboard EEPROM or configuration memory, causing loss of user settings after power cycle

- Degradation of internal power regulators, resulting in intermittent operation or module reset under load

- Corrosion or fretting on backplane connector pins, exacerbated by thermal cycling in non-climate-controlled panels

Design limitations include the absence of per-channel health diagnostics and reliance on manual configuration via DIP switches or software—making troubleshooting time-consuming. Additionally, the module lacks native digital communication (e.g., HART or Ethernet), limiting remote visibility.

Recommended preventive actions:

- Perform annual calibration using a precision simulator (e.g., Bently Nevada 9306)

- Verify alarm/trip setpoints and relay logic during scheduled outages

- Inspect for discoloration or bulging capacitors on the PCB

- Ensure proper grounding of the 3500 rack to minimize noise-induced errors

BENTLY NEVADA 3500/42M 176449-02T

Lifecycle Status and Migration Strategy

Bently Nevada has officially discontinued the 3500/42M (176449-02T). While some legacy 3500 systems remain operational globally, no new modules are manufactured, and factory repair services are no longer offered. Spare parts are sourced exclusively through third-party vendors, often at prices exceeding $4,000 per unit, with authenticity and performance reliability concerns.

As an interim measure, facilities may:

- Maintain a strategic spare inventory with periodic functional testing

- Use external signal duplication (e.g., feeding probe signals to a secondary monitor) to reduce single-point risk

- Engage specialized firms for board-level reconditioning (capacitor replacement, memory refresh)

For long-term sustainability, migration to the Bently Nevada 3500/42M Enhanced (if still available under limited support) or, preferably, the Guardian platform is recommended. Guardian offers:

- Integrated diagnostics and remote health monitoring

- Native OPC UA and Modbus TCP for seamless SCADA integration

- Compliance with IEC 61508/61511 for functional safety applications

Migration requires re-engineering I/O wiring, updating protection logic, and re-validating trip setpoints—but delivers improved reliability, cybersecurity readiness, and extended vendor support lifecycle. For plants with multiple aging 3500 racks, a phased transition plan aligned with major overhauls is the most cost-effective approach.

Tel:

Tel:  Email:

Email:  WhatsApp:

WhatsApp: